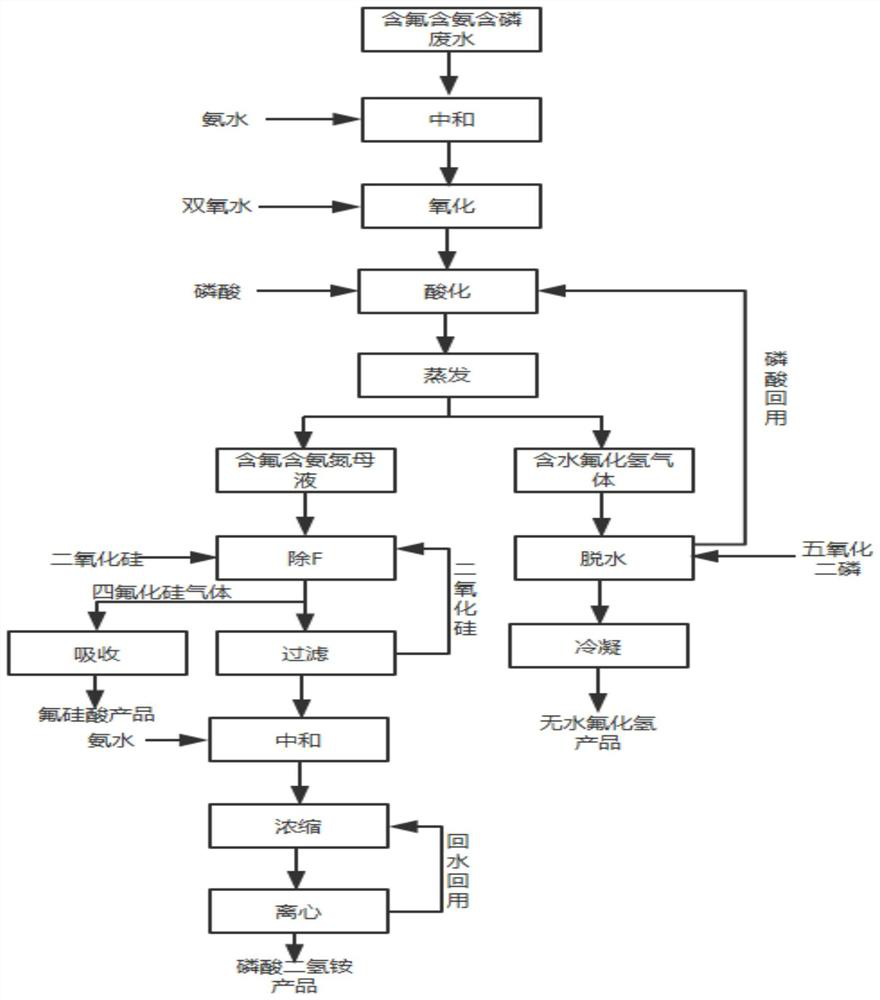

A treatment method for wastewater containing fluorine, ammonia, nitrogen and phosphorus

A treatment method and wastewater technology, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve problems such as large limitations, large lime dosage, and calcium easily exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the fluorine-containing ammonia nitrogen-containing phosphorus wastewater, the fluorine content is 40 g / L, the ammonia nitrogen content is 15 g / L, and the phosphorous and hypophosphorous content is 0.5 g / L. Pour 2 tons of waste water containing fluorine, ammonia, nitrogen, and phosphorus into the reactor, add ammonia water to adjust the pH to 8.0, start stirring, slowly add 100 L of hydrogen peroxide, and raise the temperature to 40°C for 1 hour. Add 200L of concentrated phosphoric acid, evaporate at 120°C, 0.09MPa, dry the gas through the pipeline at 60°C with phosphorus pentoxide, and condense at 5°C to obtain anhydrous hydrogen fluoride. After measuring the fluorine content of the mother liquor, transfer it to another reactor, add 1.1 times the theoretical amount of silicon dioxide and stir for 1 hour to remove fluorine. The content of fluosilicic acid in the spray liquid of the spray tower was measured to be 20 wt%, and the water in the spray tower was changed. ...

Embodiment 2

[0027] In the fluorine-containing ammonia nitrogen-containing phosphorus wastewater, the fluorine content is 45 g / L, the ammonia nitrogen content is 17.5 g / L, and the phosphorous and hypophosphorous content is 0.75 g / L. Pour 2 tons of waste water containing fluorine, ammonia, nitrogen, and phosphorus into the reactor, add ammonia water to adjust the pH to 8.5, start stirring, slowly add 150 L of hydrogen peroxide, and raise the temperature to 50°C for 1.5 hours. Add 220L of concentrated phosphoric acid and evaporate at 125°C and 0.095MPa. The gas passes through the pipeline and is dried by phosphorus pentoxide at 70°C. After condensation at 8°C, anhydrous hydrogen fluoride is obtained. After measuring the fluorine content of the mother liquor, transfer it to another reactor, add 1.15 times the theoretical amount of silicon dioxide and stir for 1.5 hours to remove fluorine. The content of fluosilicic acid in the spray liquid of the spray tower was measured to be 23 wt%, and the...

Embodiment 3

[0029] In the fluorine-containing ammonia nitrogen-containing phosphorus wastewater, the fluorine content is 50 g / L, the ammonia nitrogen content is 20 g / L, and the phosphorous and hypophosphorous content is 1 g / L. Pour 2 tons of waste water containing fluorine, ammonia, nitrogen, and phosphorus into the reactor, add ammonia water to adjust the pH to 9, start stirring, slowly add 200 L of hydrogen peroxide, and heat up to 60°C for 2 hours. Add 240L of concentrated phosphoric acid, evaporate at 130°C, 0.1MPa, dry the gas through the pipeline at 80°C with phosphorus pentoxide, and condense at 10°C to obtain anhydrous hydrogen fluoride. After measuring the fluorine content of the mother liquor, transfer it to another reactor, add 1.2 times the theoretical amount of silicon dioxide and stir for 2 hours to remove fluorine, and press filter to collect the silicon dioxide for reuse in the next F removal. The content of fluosilicic acid in the spray liquid of the spray tower was measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com