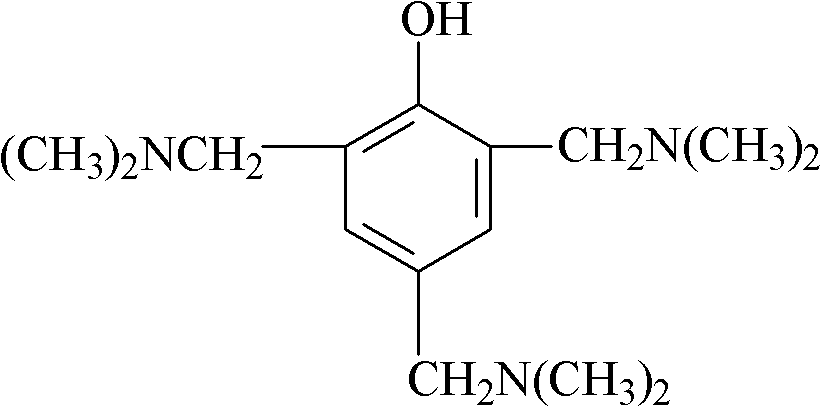

DMP-30 (dimethyl phthalate-30) closing method and application of DMP-30 in epoxy adhesive

A DMP-30, weight percentage technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of short operation time, too fast gel, etc., and achieve the effect of easy operation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

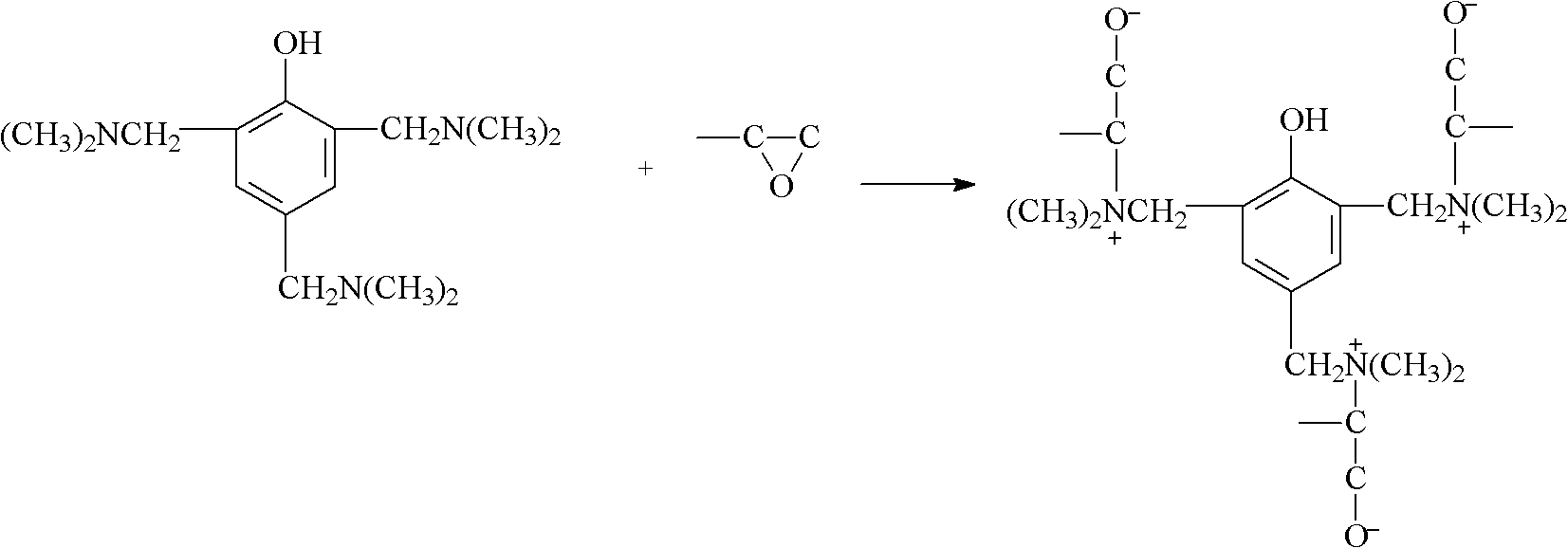

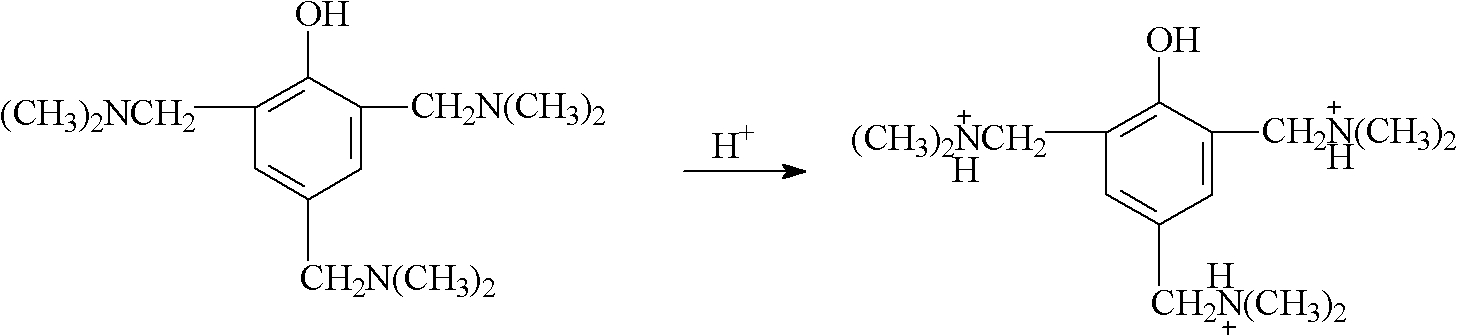

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Accurately weigh each raw material according to the following weight percentages, the amount of DMP-30 is 90%, and phosphorous acid is 10%. Through the simple physical mixing of the two, after mixing evenly, the pH value of the formed mixture is 7.1, and the mixture is kept at room temperature for use. Its application in epoxy adhesive consists of the following raw materials: 30% of 828EL epoxy resin, 2% of tert-butyl carbonate glycidyl ether diluent, 30% of Nanjing Huayuan silicon powder NF110, sealed DMP- 30 38%. Put the above components into the double planetary power mixing mixer in turn, evacuate until the vacuum degree is -0.08 ~ -0.05MPa, stir at 500 rpm for 2 hours, and stir evenly.

Embodiment 2

[0027] Accurately weigh each raw material according to the following weight percentages, the amount of DMP-30 is 80%, and the amount of citric acid is 20%. Through the simple physical mixing of the two, after mixing evenly, the pH value of the formed mixture is 9.8, and the mixture is kept at room temperature for use. Its application in epoxy adhesive consists of the following raw materials: E51 epoxy resin 25%, H8 diluent 5%, 600 mesh silica powder filler 54%, KH560 coupling agent 1%, sealed DMP-30 15 %. Put the above components into the double planetary power mixing mixer in turn, evacuate until the vacuum degree is -0.08 ~ -0.05MPa, stir at 500 rpm for 2 hours, and stir evenly.

Embodiment 3

[0029] Accurately weigh each raw material according to the following percentages by weight, the amount of DMP-30 is 60%, and the amount of oleic acid is 40%. Through the simple physical mixing of the two, after mixing evenly, the pH value of the formed mixture is 8.3, and the mixture is kept at room temperature for use. Its application in epoxy adhesives consists of the following raw materials: 8240 epoxy resin 44%, 1,4 butanediol glycidyl ether diluent 1%, 600 mesh silica powder filler 29%, KH560 coupling agent 1% , DMP-30 after sealing 25%. Put the above components into the double planetary power mixing mixer in turn, evacuate until the vacuum degree is -0.08~-0.05MPa, stir at 500 rpm for 2 hours, and stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com