Preparation method of polyester

A technology of polyester and polyester, applied in the field of organic polymer materials, can solve the problems of fast catalysis speed and controllable molecular weight, and achieve the effects of fast catalysis speed, controllable molecular weight and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] In a 10 mL polymerization tube, add D-lactide (0.432 g, 3 mmol), compound (9) (0.109 g, 0.3 mmol), DMAP (13.5 μL, 0.1 mmol), pentaerythritol (9.7 μL, 0.1 mmol), Stir magnetically at 140°C for 4 hours, stop the reaction, add a small amount of dichloromethane dropwise to the resulting mixture to dissolve, then slowly drop the resulting solution into cold methanol, a white polymer precipitates, centrifuge and vacuum dry to obtain 0.28g of the product , the conversion rate was 97.2%, the number-average molecular weight Mn of poly-D-lactide was 4610 g / mol, and the molecular weight distribution PDI was 1.21.

Embodiment 2

[0066] In a 10 mL polymerization tube, add d-lactide (0.0432 g, 0.3 mmol), compound (3) (0.115 g, 0.3 mmol), DBU (15.0 μL, 0.1 mmol), pentaerythritol (9.7 μL, 0.1 mmol) , Stir magnetically for 5 hours at 40°C, stop the reaction, add a small amount of dichloromethane dropwise to the resulting mixture to dissolve, then slowly drop the resulting solution into cold methanol, a white polymer is precipitated, and the product 0.03 is obtained by centrifugation and vacuum drying. g, the conversion rate is 97.6%, the number average molecular weight M of poly d-lactide n It is 500 g / mol, and the molecular weight distribution PDI is 1.11.

Embodiment 3

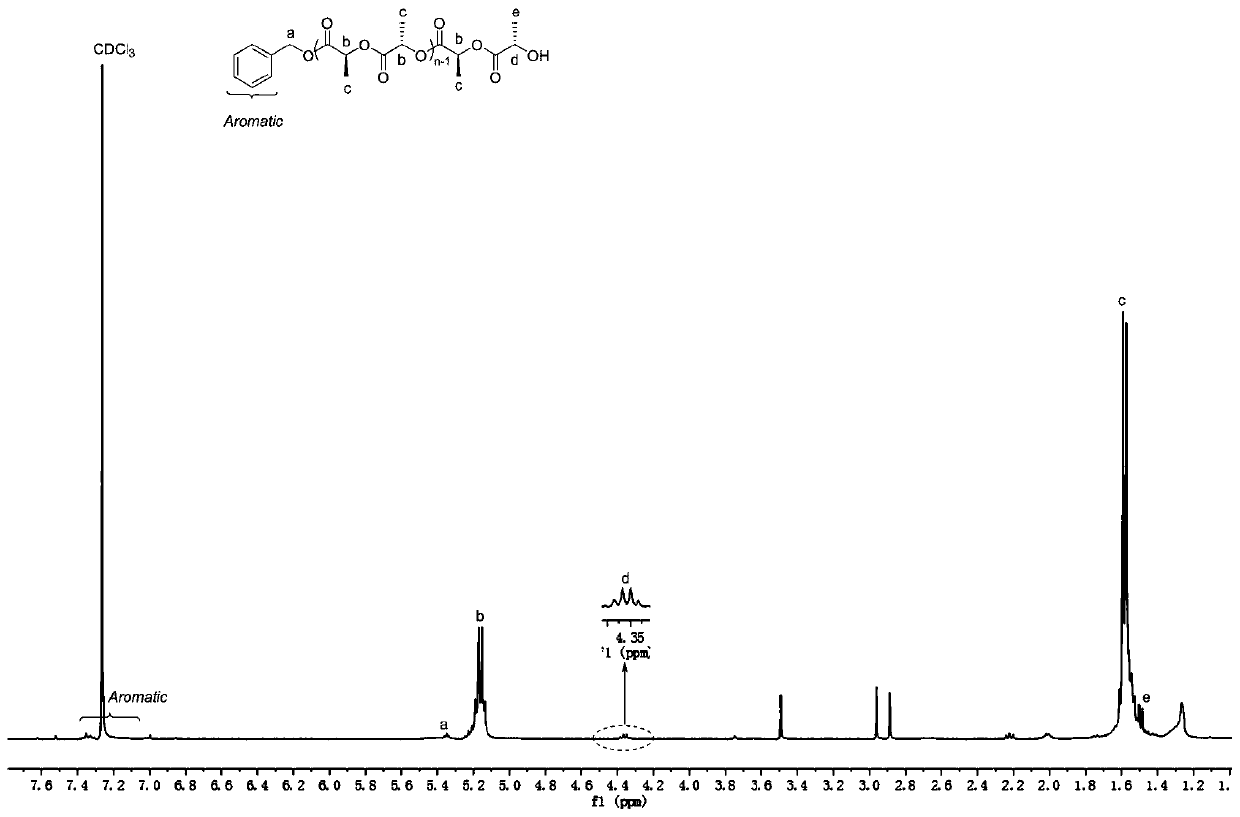

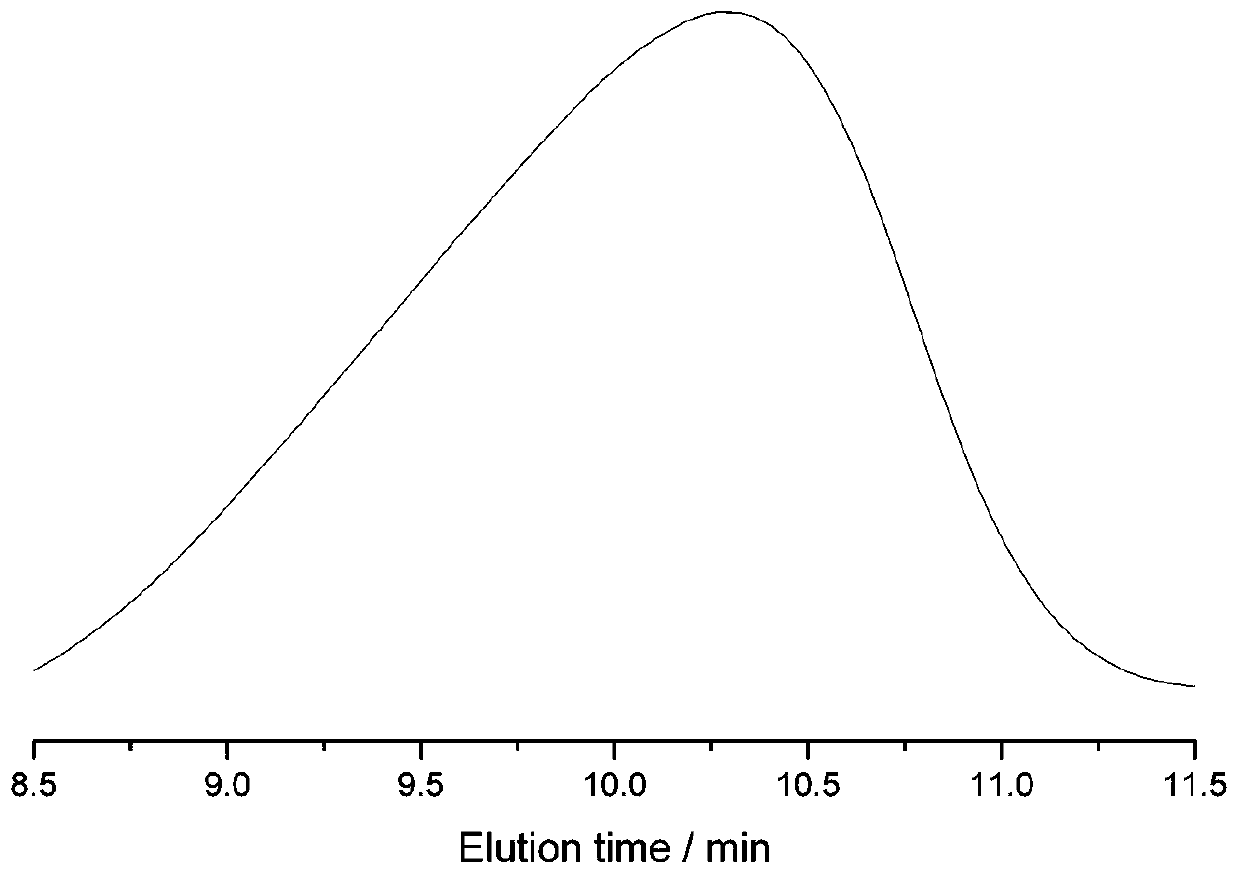

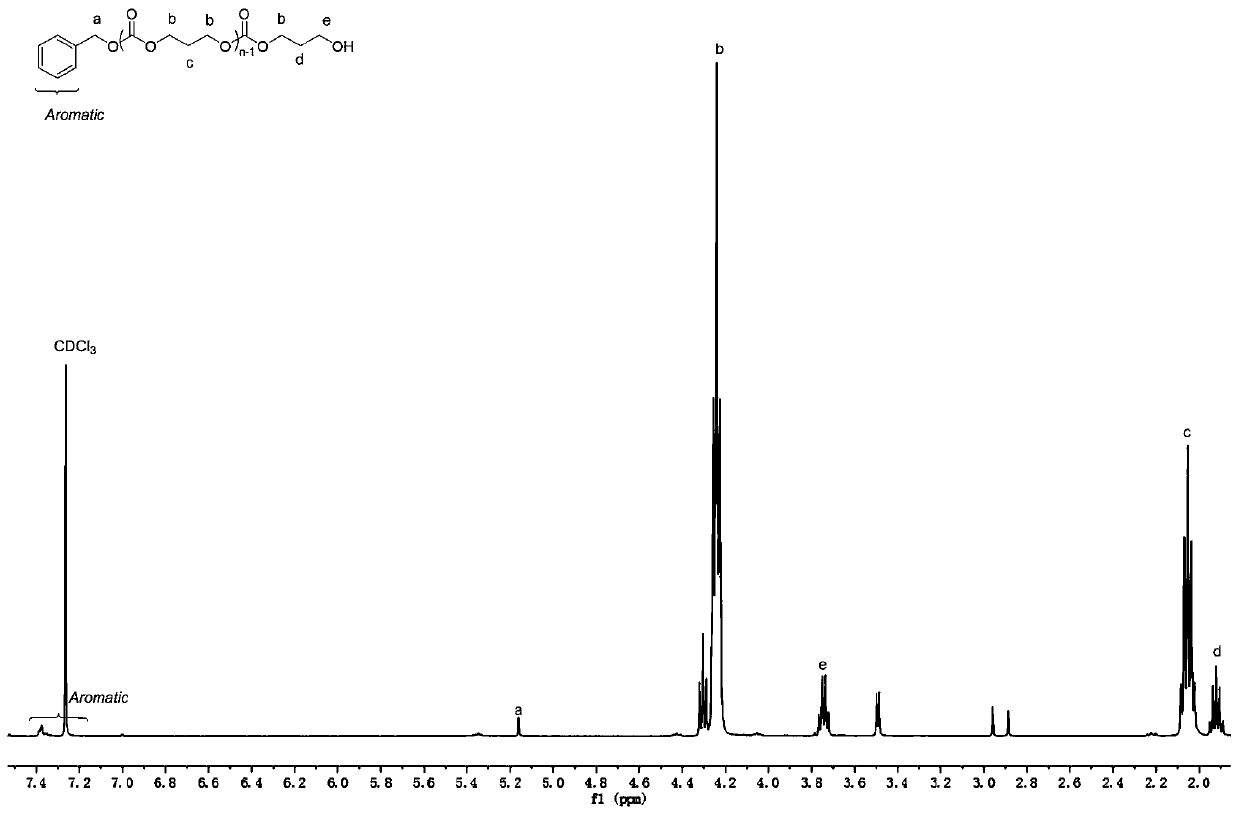

[0068] In a 10 mL polymerization tube, add l-lactide (0.432 g, 3 mmol), compound (4) (0.109 g, 0.3 mmol), DBU (15.0 μL, 0.1 mmol), benzyl alcohol (10.0 μL, 0.1 mmol) , Stir magnetically for 1.5 hours at 130°C, stop the reaction, add a small amount of dichloromethane dropwise to the resulting mixture to dissolve, then slowly drop the resulting solution into cold methanol, a white polymer is precipitated, and the product 0.36 is obtained by centrifugation and vacuum drying. g, the conversion rate is 99.5%, the number average molecular weight M of poly-l-lactide n It is 5389 g / mol, and the molecular weight distribution PDI is 1.19. (attached figure 1 , 2 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com