Polyvinyl alcohol crosslinked hyaluronic acid gel and preparation method thereof

A technology of hyaluronic acid and polyvinyl alcohol, applied in the field of polyvinyl alcohol-crosslinked hyaluronic acid gel and its preparation, can solve the problems of insufficient transparency, reduced purity, hidden safety hazards and the like, and achieve high purity and less impurities , the effect of low impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

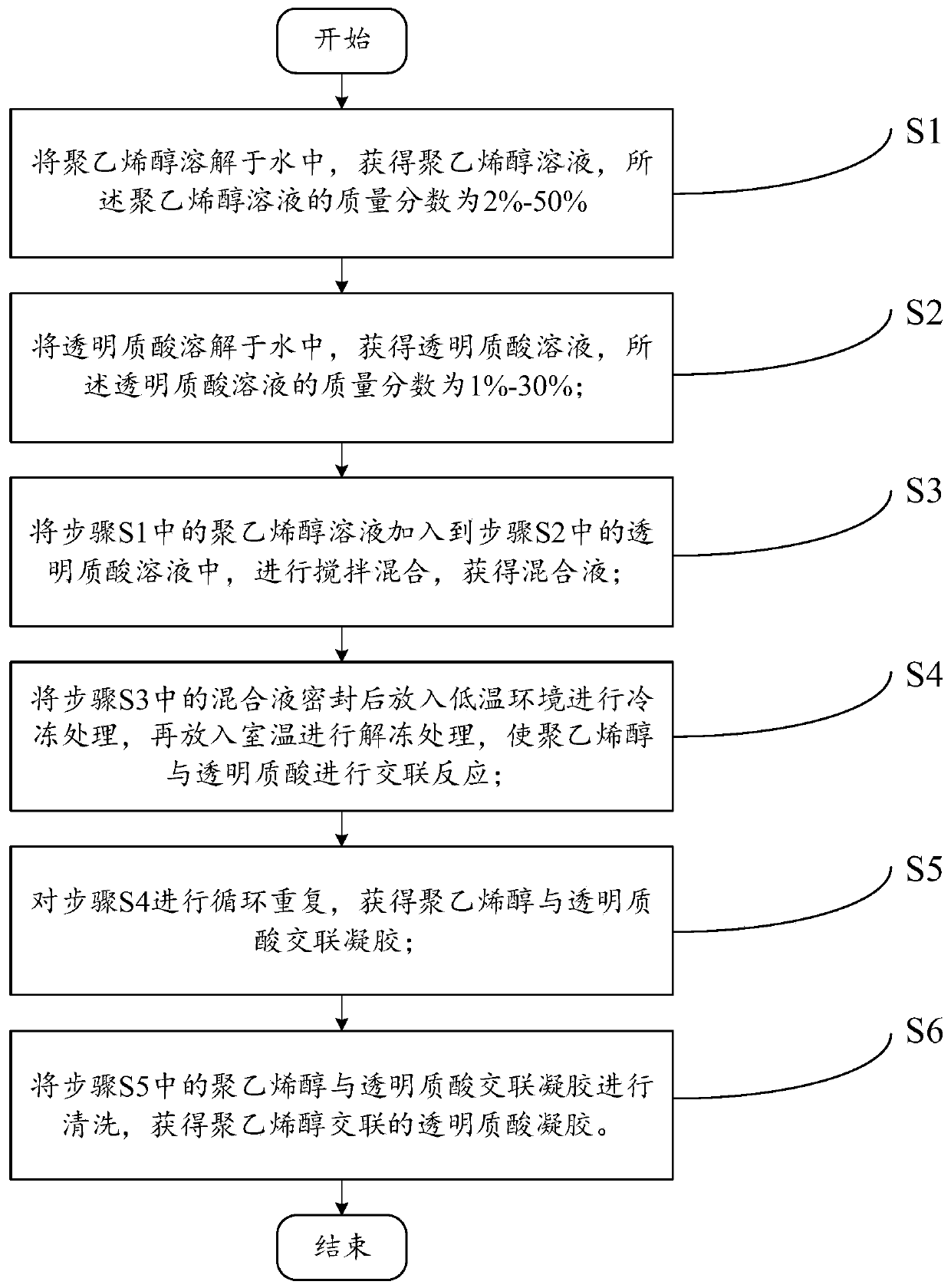

[0024] The present embodiment provides the preparation method of polyvinyl alcohol cross-linked hyaluronic acid gel, comprising the following steps:

[0025] S1, dissolving polyvinyl alcohol in water to obtain a polyvinyl alcohol solution, the mass fraction of the polyvinyl alcohol solution is 50%, wherein the molecular weight of hyaluronic acid is 20,000 Daltons;

[0026] S2, dissolving hyaluronic acid in water to obtain a hyaluronic acid solution, the mass fraction of the hyaluronic acid solution is 1%, and the molecular weight of polyvinyl alcohol is 2 million Daltons;

[0027] S3, adding the polyvinyl alcohol solution in step S1 to the hyaluronic acid solution in step S2, stirring and mixing according to the mass ratio of the hyaluronic acid solution and the polyvinyl alcohol solution being 1:1, to obtain a mixed solution;

[0028] S4, after sealing the mixed solution in step S3, put it into freezing treatment at 0° C. for 24 hours, and then put it into room temperature fo...

Embodiment 2

[0033] The present embodiment provides the preparation method of polyvinyl alcohol cross-linked hyaluronic acid gel, comprising the following steps:

[0034] S1, dissolving polyvinyl alcohol in water to obtain a polyvinyl alcohol solution, the mass fraction of the polyvinyl alcohol solution is 2%, wherein the molecular weight of hyaluronic acid is 10,000 Daltons;

[0035] S2, dissolving hyaluronic acid in water to obtain a hyaluronic acid solution, the mass fraction of the hyaluronic acid solution is 30%, wherein the molecular weight of polyvinyl alcohol is 300,000 Daltons;

[0036] S3, adding the polyvinyl alcohol solution in step S1 to the hyaluronic acid solution in step S2, stirring and mixing according to the mass ratio of the hyaluronic acid solution and the polyvinyl alcohol solution being 100:1, to obtain a mixed solution;

[0037] S4, after sealing the mixed solution in step S3, put it into freezing treatment at -60°C for 1 hour, and then put it into room temperature ...

Embodiment 3

[0042] The present embodiment provides the preparation method of polyvinyl alcohol cross-linked hyaluronic acid gel, comprising the following steps:

[0043] S1, dissolving polyvinyl alcohol in water to obtain a polyvinyl alcohol solution, the mass fraction of the polyvinyl alcohol solution is 25%, wherein the molecular weight of hyaluronic acid is 150,000 daltons;

[0044] S2, dissolving hyaluronic acid in water to obtain a hyaluronic acid solution, the mass fraction of the hyaluronic acid solution is 15%, wherein the molecular weight of polyvinyl alcohol is 1 million Daltons;

[0045] S3, adding the polyvinyl alcohol solution in step S1 to the hyaluronic acid solution in step S2, stirring and mixing according to the mass ratio of the hyaluronic acid solution and the polyvinyl alcohol solution being 50:1, to obtain a mixed solution;

[0046] S4, after sealing the mixed solution in step S3, put it into freezing treatment at -30°C for 12 hours, and then put it into room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com