Vertical pre-perforation device in cubic original rock sample borehole and pre-perforation processing method

A technology in a cube and a borehole, which is applied to the vertical pre-perforation device and the pre-perforation processing field in the borehole of the original rock sample of the cube, and can solve the problems of difficulty in making the original rock sample and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

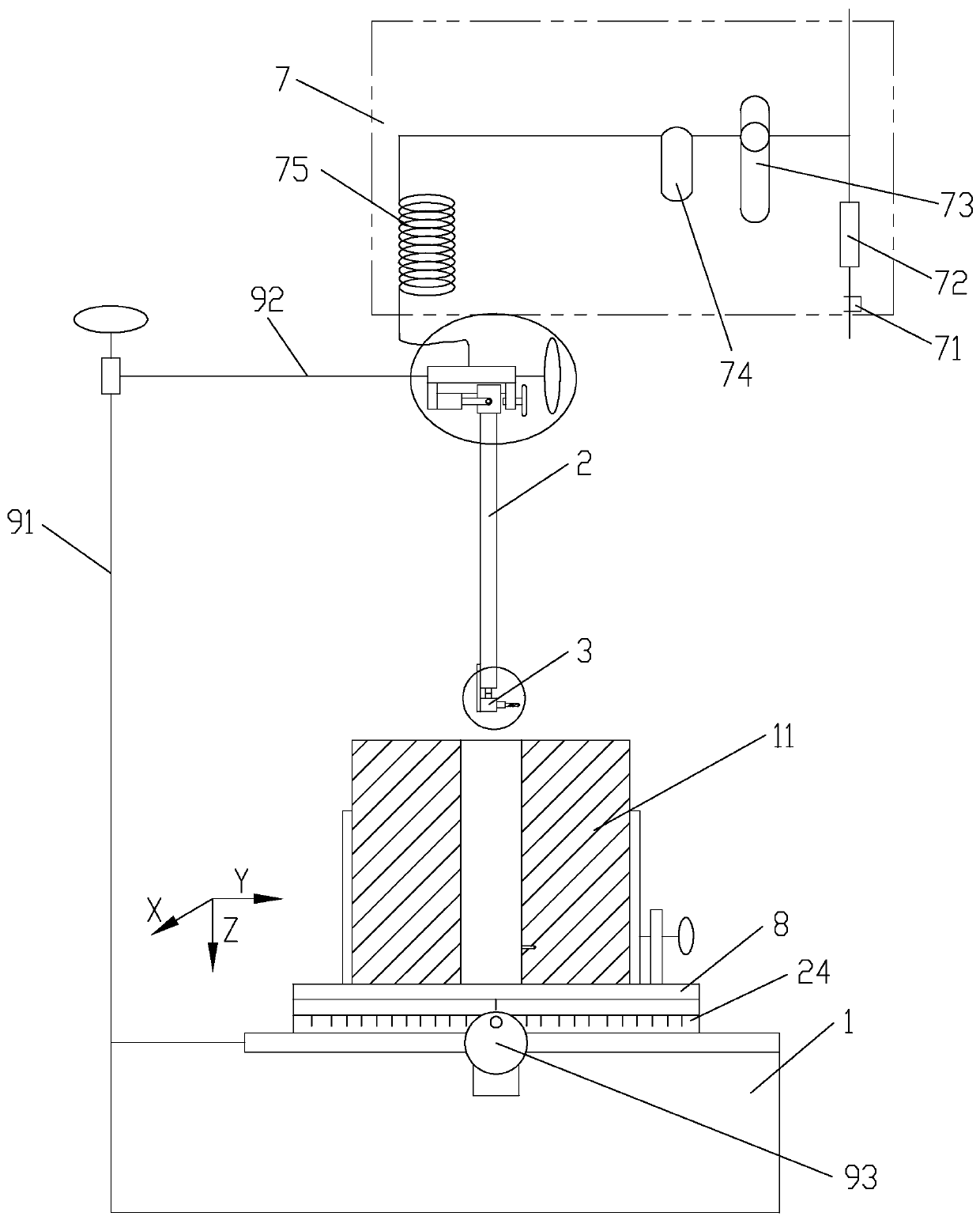

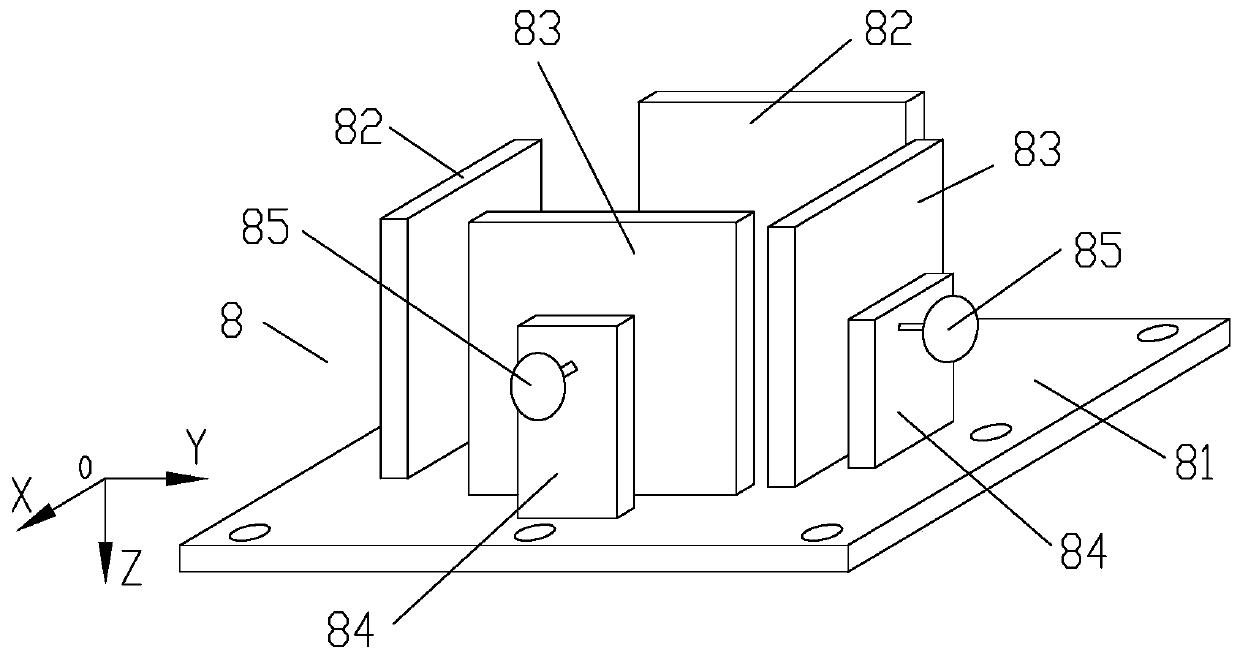

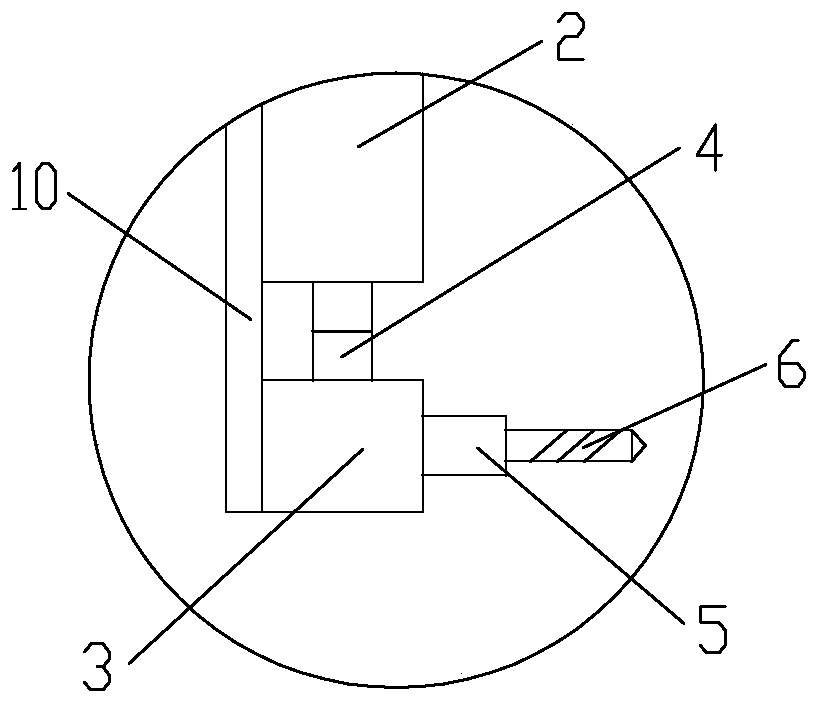

[0047] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , a vertical pre-perforation device in a cube original rock sample borehole, comprising a base platform 1, an air drill, a sample holder 8, an air pressure control device 7 and a position adjustment device; the air drill and the sample holder All devices 8 are connected to the base platform 1 through a position adjustment device; the sample holder 8 is set on the base platform 1 so that it can move horizontally and laterally; the air drill can be vertically lifted and horizontally moved The ground is arranged above the base platform 1; the air drill is also connected with a pressure gas source through the air pressure control device 7; The output end of the pneumatic motor 2 is connected with a right-angle steering transmission device 3, and the housing of the right-angle steering transmission device 3 and the housing of the miniature pneumatic motor 2 are connected through a connecting block 10 to form a rel...

Embodiment 2

[0052] Example 2, combined with figure 1 , figure 2 , image 3 , Figure 4 , a vertical pre-perforation processing method in the borehole of a cubic protorock sample, implemented based on the device of embodiment 1, comprising the steps of:

[0053] The first step is to determine the perforation diameter of the vertical perforation in the through hole in the middle of the cube rough sample, and select the drill bit in the diamond tool 6 of the same diameter, and fix the drill bit on the drill rod 5 by clamping;

[0054] In the second step, fix the prefabricated 300mm × 300mm × 300mm cubic protorock sample 11 with a through hole formed in the middle part on the sample holder 8 according to the vertical mode of the central through hole axis of the sample, and The position of the sample is roughly adjusted by the position adjustment device, so that the central axis of the through hole in the upper middle of the cubic protorock sample 11 is basically located on the axis moving...

Embodiment 3

[0065] Embodiment 3, a vertical pre-perforation processing method in the drilling hole of a cubic proto-rock sample, the difference between this method and embodiment 2 is that the pre-perforation section trimming is performed in the following steps: S21 in the cubic proto-rock of the seventh step After the pre-perforation at different heights in any of the same phases in the upper middle of the sample 11 is completed, the drill bit is lifted above the cubic original rock sample, and the drill bit is replaced with a grinding head; S22 repeats the fifth and sixth steps The first step is to modify the shape of the pre-perforation sections at different heights in the same phase in sequence; S23 retreats the air drill and lifts it above the cubic original rock sample 11 to prepare for the next group of pre-perforation drillers. pieces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com