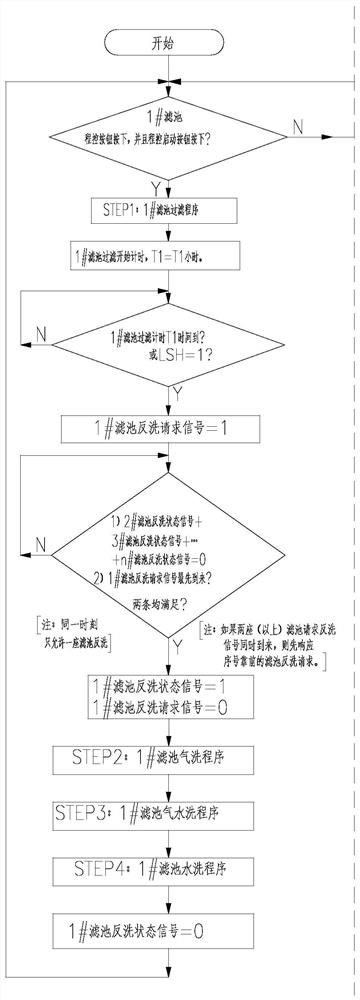

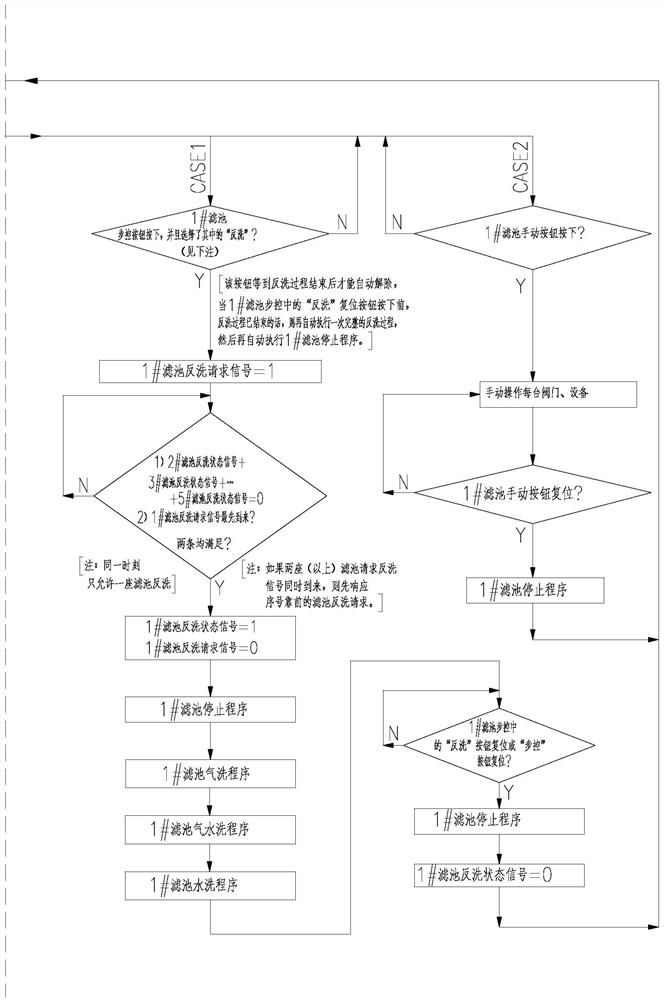

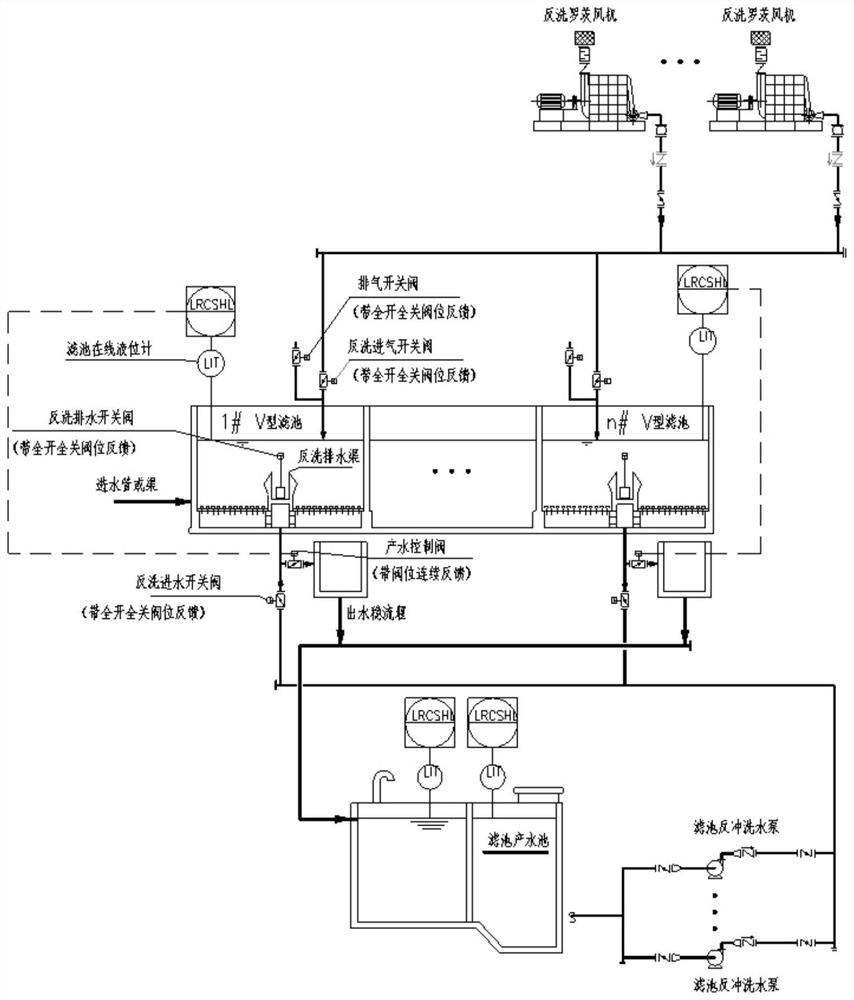

Sequence Control Configuration Method of Water Treatment System

A technology of water treatment system and control method, which is applied in the direction of program control and electrical program control in the sequence/logic controller, and can solve the problems of low degree of automation, poor robustness, waste of energy and time of operators in the central control room, etc. , to achieve the effect of improving convenience, increasing flexibility and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0198] Example 1: The V-shaped filter system of Yili Xintian coal-to-natural gas project sewage treatment and sewage reuse device (coal chemical industry zero discharge project) adopts the sequential control configuration method of this application.

Embodiment 2

[0199] Example 2: The biological aerated filter system of Yili Xintian coal-to-natural gas project sewage treatment and sewage reuse device (coal chemical industry zero discharge project) adopts the sequential control configuration method of this application.

Embodiment 3

[0200] Example 3: The ultrafiltration system of the Yili Xintian coal-to-natural gas project sewage treatment and sewage reuse device (coal chemical industry zero discharge project) adopts the sequential control configuration method of this application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com