A Radiation Hardened Outboard Orthogonal Bridge for Aerospace Vehicles

An anti-radiation reinforcement and aircraft technology, applied in the fields of aviation and aerospace communications, can solve problems such as inability to apply aerospace vehicles, inability to meet the requirements of aerospace appearance and size, and inability to apply, and achieve the effect of improving anti-irradiation capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

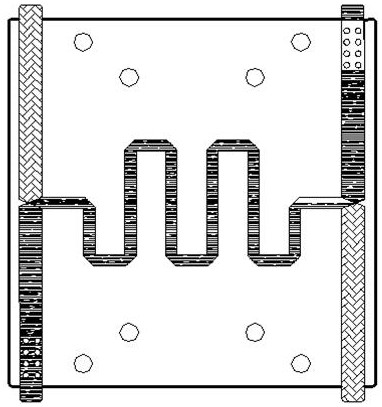

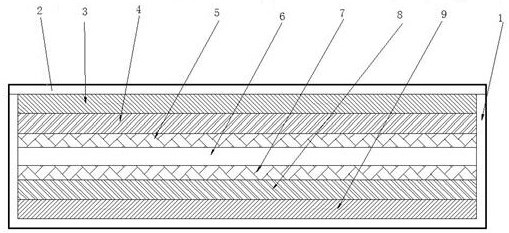

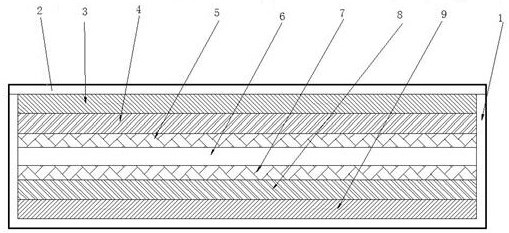

[0022] see figure 2 , a kind of anti-radiation reinforced aerospace vehicle exterior orthogonal bridge, comprising a cavity 1, an orthogonal bridge circuit in the cavity 1 and a cover plate 2 on the top of the cavity, the orthogonal bridge The bridge circuit includes an upper stainless steel plate 3, an upper lead plate 4, a top circuit board 5, a central circuit board 6, a bottom circuit board 7, a lower lead plate 8 and a lower stainless steel plate 9, and the above components are symmetrical with the center circuit board 6 as the center. arrangement;

[0023] In this embodiment, the thicknesses of the upper stainless steel plate 3 and the lower stainless steel plate 9 are the same, both being 0.5mm;

[0024] The thickness of the upper lead plate 4 is the same as that of the lower lead plate 8, which is 0.1mm;

[0025] The cavity 1 and the cover plate 2 are both made of aluminum, with a thickness of 4.0mm;

[0026] The circuit materials, that is, the top circuit board 5 ...

Embodiment 2

[0031] In this example,

[0032] The upper stainless steel plate 3 has the same thickness as the lower stainless steel plate 9, which is 0.5mm;

[0033] The thickness of the upper lead plate 4 is the same as that of the lower lead plate 8, which is 0.5mm;

[0034] The cavity 1 and the cover plate 2 are both made of aluminum, with a thickness of 4.0 mm, and the rest of the structure is the same as that of Embodiment 1;

[0035] The orthogonal electric bridge of the present embodiment adopting the above-mentioned structure, anti-radiation ability is:

[0036] Anti-irradiation radiation dose: 25Mrad (Si) / metering rate: 2 ~ 50rad / Si / s conditions;

[0037] Reduce the protective volume by more than 35%, and reduce the protective weight by about 40% (about 25g).

Embodiment 3

[0039] In this example,

[0040] The upper stainless steel plate 3 has the same thickness as the lower stainless steel plate 9, both of which are 1.0mm;

[0041] The thickness of the upper lead plate 4 is the same as that of the lower lead plate 8, which is 0.5mm;

[0042] The cavity 1 and the cover plate 2 are both made of aluminum, with a thickness of 4.0mm; the rest of the structure is the same as in Example 1

[0043] The orthogonal electric bridge of the present embodiment adopting the above-mentioned structure, anti-radiation ability is:

[0044] Anti-irradiation radiation dose: 50Mrad (Si) / metering rate: 2 ~ 50rad / Si / s conditions;

[0045] Reduce the protective volume by more than 25%, and reduce the protective weight by about 35% (about 15g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com