Method and device for continuous production of polyols for polyester

A technology of polyols and polyesters, applied in chemical instruments and methods, preparation of organic compounds, carbon-based compounds, etc., can solve the problem of difficult to achieve tens of thousands of tons of production scale, unrestricted expansion of reactors, and influence on product quality Stability and other issues, to achieve the effect of inhibiting various side reactions, reducing sewage discharge, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

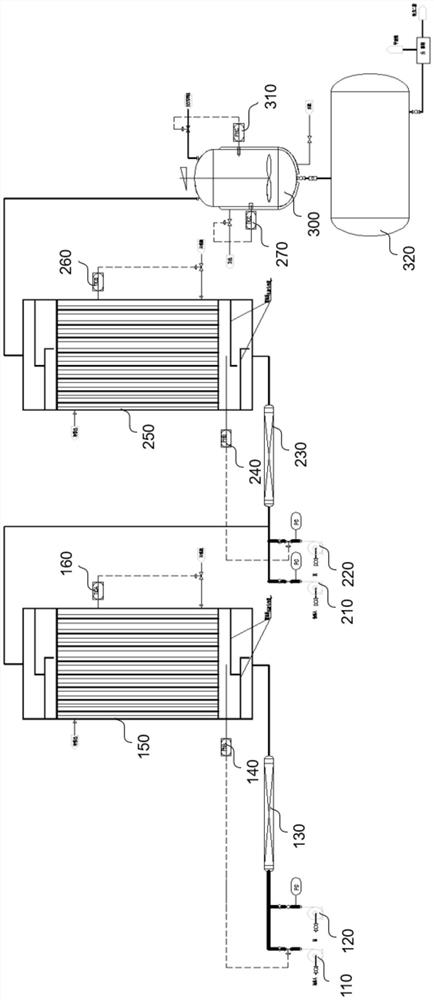

Image

Examples

Embodiment 1

[0028] ① The material formaldehyde and 40% liquid caustic soda are mixed in a certain proportion through the metering pump, and the pH value online detector is installed on the mixed material pipeline, and the liquid caustic caustic feed valve is controlled to make the pH value 9.0-11.0;

[0029] The material n-butyraldehyde is added in a certain proportion in the mixing section of the multi-channel tubular reactor in a tangential direction through the metering pump, and enters the mixing section of the multi-channel tubular reactor. The material reacts with the material and enters the multi-channel reaction section. Adjust the opening of the cooling water regulating valve through the temperature gauge T1 signal in the reaction section to ensure that the temperature is controlled at 40°C. The flow rate of the reaction liquid in the pipeline reactor is 0.05m / s, and the residence time is controlled for 1-2h to obtain the intermediate hydroxypivalaldehyde.

[0030] ② The intermed...

Embodiment 2

[0034] ① The material formaldehyde and 32% liquid caustic soda are mixed in a certain proportion through the metering pump, and the pH value online detector is installed on the mixed material pipeline, and the liquid caustic caustic feed valve is controlled to make the pH value 9.0-11.0;

[0035] The material n-butyraldehyde is added in a certain proportion in the mixing section of the multi-channel tubular reactor in a tangential direction through the metering pump, and enters the mixing section of the multi-channel tubular reactor. The material reacts with the material and enters the multi-channel reaction section. Adjust the opening of the cooling water regulating valve through the temperature gauge T1 signal in the reaction section to ensure that the temperature is controlled at 40°C. The flow rate of the reaction solution in the pipeline reactor is 0.05m / s, and the residence time is controlled for 1-2h to obtain the intermediate 2,2-dimethylolbutyraldehyde.

[0036] ② The...

Embodiment 3

[0040] ① The material formaldehyde and 40% liquid caustic soda are mixed in a certain proportion through the metering pump, and the mixed material pipeline is equipped with a pH value online detector, and the liquid caustic caustic feed valve is controlled to make the pH value 9.0 to 11.0.

[0041] The material acetaldehyde is added in a certain proportion in the mixing section of the multi-channel tubular reactor in a tangential direction through the metering pump, and enters the mixing section of the multi-channel tubular reactor. The material reacts with the material and enters the multi-channel reaction section. Adjust the opening of the cooling water regulating valve through the temperature gauge T1 signal in the reaction section to ensure that the temperature is controlled at 40°C. The flow rate of the reaction solution in the pipeline reactor is 0.01m / s, and the residence time is controlled for 1-2h to obtain the intermediate trimethylol acetaldehyde solution.

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com