Method capable of simultaneously preparing avermectin B2a fine powder and ointment

A technology of abamectin and refined powder is applied in the field of simultaneously preparing abamectin B2a refined powder and ointment, which can solve the problems of lack of drug efficacy and the like, and achieve the effect of expanding the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

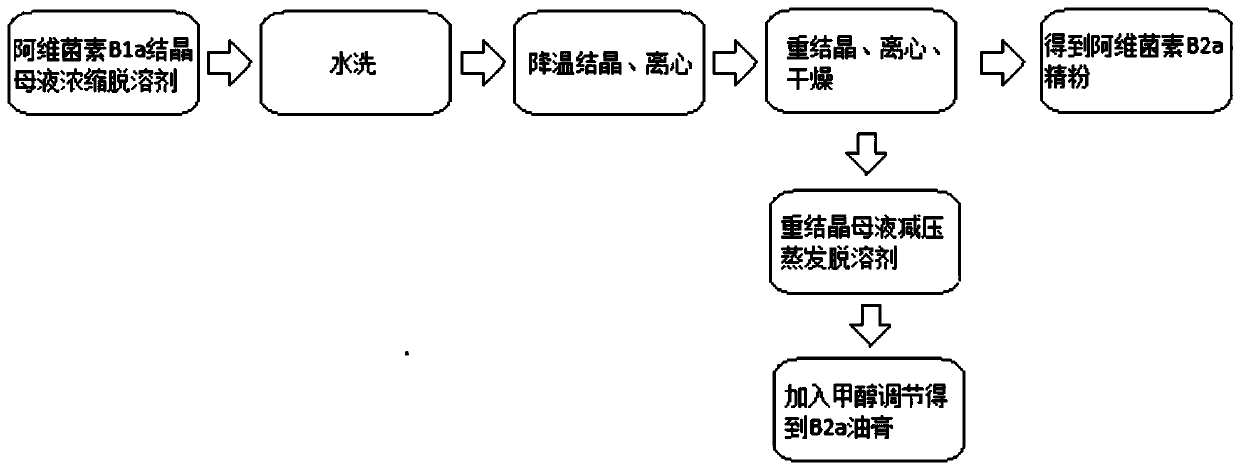

[0024] like figure 1 Shown, a kind of method that can prepare Abamectin B2a fine powder and ointment simultaneously, comprises the steps:

[0025] (a) Abamectin B1a crystallization mother liquor is concentrated and desolvated: the abamectin B1a crystallization mother liquor is evaporated under reduced pressure to obtain a concentrate, and toluene is added to the concentrate and heated to 83° C. and stirred for 35 minutes to fully dissolve, and the extraction is obtained. Liquid, wherein, the volume ratio of the added amount of toluene to the concentrate is 2.8:1;

[0026] (b) Washing with water: add 83°C hot water with 28% volume of the extract, stir for 33 minutes, let stand for 1.5 hours, remove the water phase and emulsion phase, and obtain the extract after washing;

[0027] (c) Cooling crystallization and centrifugation: cooling the washed extract to 3° C. in a circulating water bath and maintaining it for 3 hours; using a centrifuge to centrifuge in a closed manner to o...

Embodiment 2

[0032] like figure 1 Shown, a kind of method that can prepare Abamectin B2a fine powder and ointment simultaneously, comprises the steps:

[0033] (a) Abamectin B1a crystallization mother liquor is concentrated and desolventized: Abamectin B1a crystallization mother liquor is evaporated and desolvated under reduced pressure to obtain a concentrate, and toluene is added to the concentrate and heated to 80° C. and stirred for 30 minutes to fully dissolve to obtain an extraction Liquid, wherein, the volume ratio of the added amount of toluene to the concentrate is 2.5:1;

[0034] (b) Washing: add 80°C hot water with 25% volume of the extract, stir for 30 minutes, let stand for 1 hour, remove the water phase and the milk phase, and obtain the extract after washing;

[0035] (c) Cooling crystallization and centrifugation: cooling the washed extract to 0° C. in a circulating water bath and maintaining it for 2 hours; centrifuging in a centrifuge to obtain primary coarse crystals of...

Embodiment 3

[0040] like figure 1 Shown, a kind of method that can prepare Abamectin B2a fine powder and ointment simultaneously, comprises the steps:

[0041] (a) Abamectin B1a crystallization mother liquor is concentrated and desolventized: the abamectin B1a crystallization mother liquor is evaporated under reduced pressure to obtain a concentrate, and toluene is added to the concentrate and heated to 85° C. and stirred for 45 minutes to fully dissolve, and the extraction is obtained. Liquid, wherein, the volume ratio of the added amount of toluene to the concentrate is 3.0:1;

[0042] (b) washing with water: adding 85°C hot water with 30% volume of the extract, stirring for 35 minutes, standing for 2 hours, removing the water phase and the milk phase, and obtaining the extract after washing;

[0043] (c) Cooling crystallization and centrifugation: cooling the washed extract to 5° C. in a circulating water bath and maintaining it for 4 hours; using a centrifuge to centrifuge in a sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com