Compound ulva extract with auxiliary anti-tumor effect and preparation technology of compound ulva extract

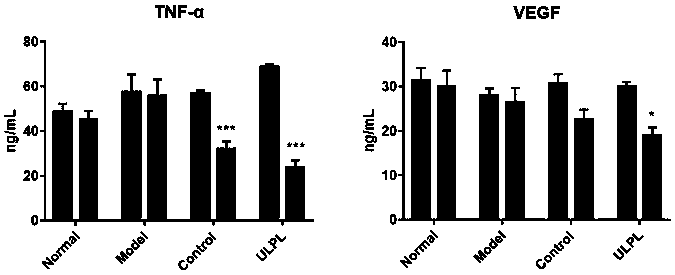

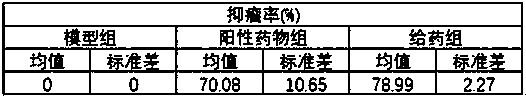

A technology of extract and anti-tumor activity, which is applied in the field of medicine to achieve the effects of small side effects, inhibition of growth and spread, and definite killing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Ulva is soaked and desalted by conventional methods, dried and crushed, and 60% v / v ethanol is added to Ulva dry powder for reflux extraction for 1 hour. The ratio of dry powder weight g to ethanol volume mL is 1:20, and then dried after reflux Dried to obtain dried degreased Ulva powder, reclaim ethanol for recycling;

[0027] (2) Add distilled water to the degreased Ulva powder prepared in step (1), wherein the ratio of Ulva mass g to distilled water volume mL is 1:30, and at an extraction temperature of 60° C., assisted extraction with 350W ultrasonic waves for 120 minutes, Then leaching in hot water at 80°C for 2 hours, after the extraction, filter, repeat the extraction of the filter residue twice, combine the filtrate, centrifuge at 4000rpm for 10 minutes, and concentrate the supernatant under reduced pressure at 65°C to the original volume Add 95% v / v ethanol to make the ethanol concentration in the system reach 80% v / v, then let it stand at 4°C for 8 hours, ...

Embodiment 2

[0037] (1) Ulva is soaked and desalted by conventional methods, dried and pulverized, and 70% v / v ethanol is added to Ulva dry powder for reflux extraction for 2 hours. The ratio of dry powder weight g to ethanol volume mL is 1:25, and then dried after reflux Dried to obtain dried degreased Ulva powder, reclaim ethanol for recycling;

[0038] (2) Add distilled water to the degreased Ulva powder prepared in step (1), wherein the ratio of the mass g of Ulva to the volume mL of distilled water is 1:35, and extract with 400W ultrasonic wave for 120 minutes at an extraction temperature of 65°C, Then leaching in hot water at 85°C for 3 hours, after the extraction, filter, repeat the extraction of the filter residue 3 times, combine the filtrate, centrifuge at 4500rpm for 15 minutes, and concentrate the supernatant under reduced pressure at 65°C to the original volume Add 95% v / v ethanol to make the ethanol concentration in the system reach 80% v / v, then let it stand at 4°C for 12 ho...

Embodiment 3

[0048] (1) Ulva is soaked and desalted by conventional methods, dried and crushed, and 80% v / v ethanol is added to Ulva dry powder for reflux extraction for 2 hours. The ratio of dry powder weight g to ethanol volume mL is 1:30, and then dried after reflux Dried to obtain dried degreased Ulva powder, reclaim ethanol for recycling;

[0049] (2) Add distilled water to the degreased Ulva powder prepared in step (1), wherein the ratio of the mass g of Ulva to the volume mL of distilled water is 1:40, and extract with 400W ultrasonic wave for 120 minutes at an extraction temperature of 70°C, Then leaching in hot water at 90°C for 3 hours, after the extraction, filter, repeat the extraction of the filter residue 3 times, combine the filtrate, centrifuge at 5000rpm for 20 minutes, and concentrate the supernatant under reduced pressure at 70°C to the original volume Add 95% v / v ethanol to make the ethanol concentration in the system reach 80% v / v, then let it stand at 4°C for 12 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com