Low-temperature ultrafast preparation method of ultrafine Fe3O4/RGO compound

A complex and ultra-fast technology, applied in chemical instruments and methods, magnetic field/electric field shielding, electrical components, etc., can solve problems such as high energy consumption, low efficiency, and time consumption, and achieve short time consumption, simple conditions, and reduced Cost Effect of Preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

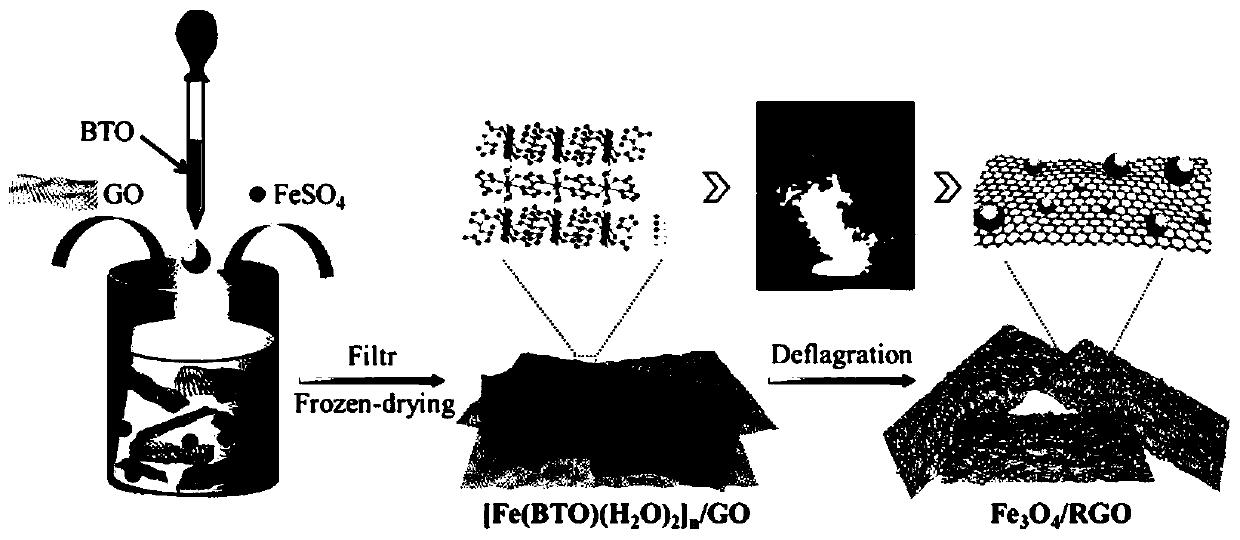

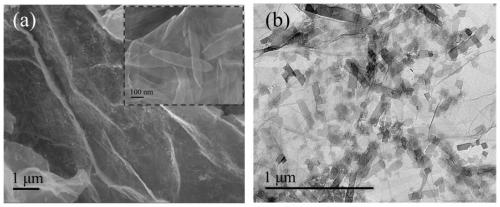

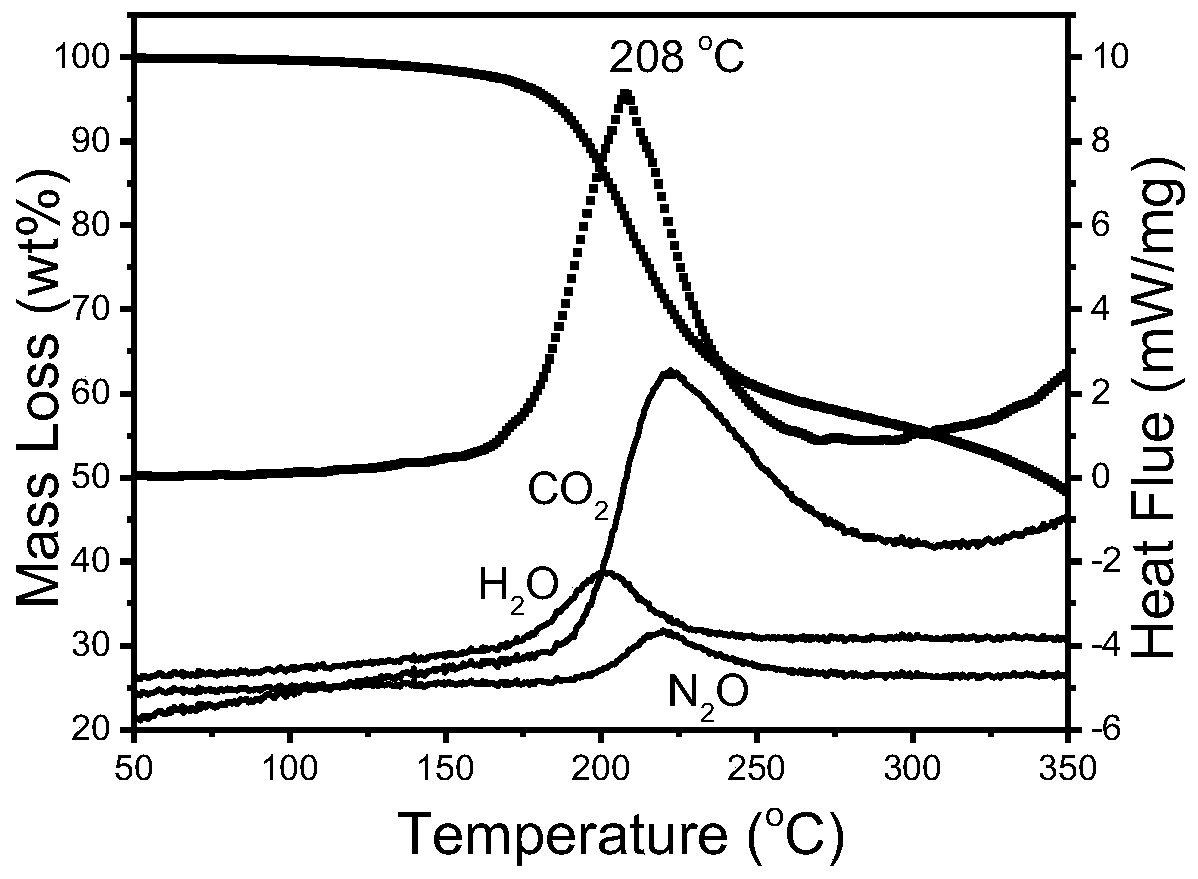

[0031] Such as figure 1 As shown, the ultra-small Fe 3 o 4 Flowchart for the preparation of the / RGO complex

[0032] At room temperature 1.13g FeSO 4 ·7H 2O, 0.1g of BTO powder and 0.15g of GO were added to 200mL of deionized water, stirred by magnetic force for 10 minutes to mix evenly and form a precipitate, after standing, remove the supernatant, centrifuge the precipitate, and slowly pour into liquid nitrogen to freeze quickly , put it in a high-pressure reactor after freeze-drying; heat the reactor to 220 ° C to trigger a deflagration reaction, collect the obtained product after the reaction, wash it repeatedly with deionized water, and obtain Fe after drying in a vacuum oven. 3 o 4 / RGO complex.

Embodiment 2

[0034] At room temperature 2.26g FeSO 4 ·7H 2 O, 0.2g of BTO powder and 0.15g of GO in 200mL of deionized water were magnetically stirred for 8 minutes to make them mix uniformly and generate a precipitate; other steps were the same as in Example 1.

Embodiment 3

[0036] At room temperature 3.39g FeSO 4 ·7H 2 O, 0.3g of BTO powder and 0.15g of GO in 200mL of deionized water were magnetically stirred for 12 minutes to make them mix uniformly and generate a precipitate; other steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com