Equipment for preheating and cracking waste tires on basis of solar energy

A technology of waste tires and solar energy, which is applied in the preparation of liquid hydrocarbon mixtures, energy input, products, etc., can solve the problems of undisclosed pyrolysis heating, etc., and achieve the effects of compact structure, high convective heat transfer coefficient, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment one

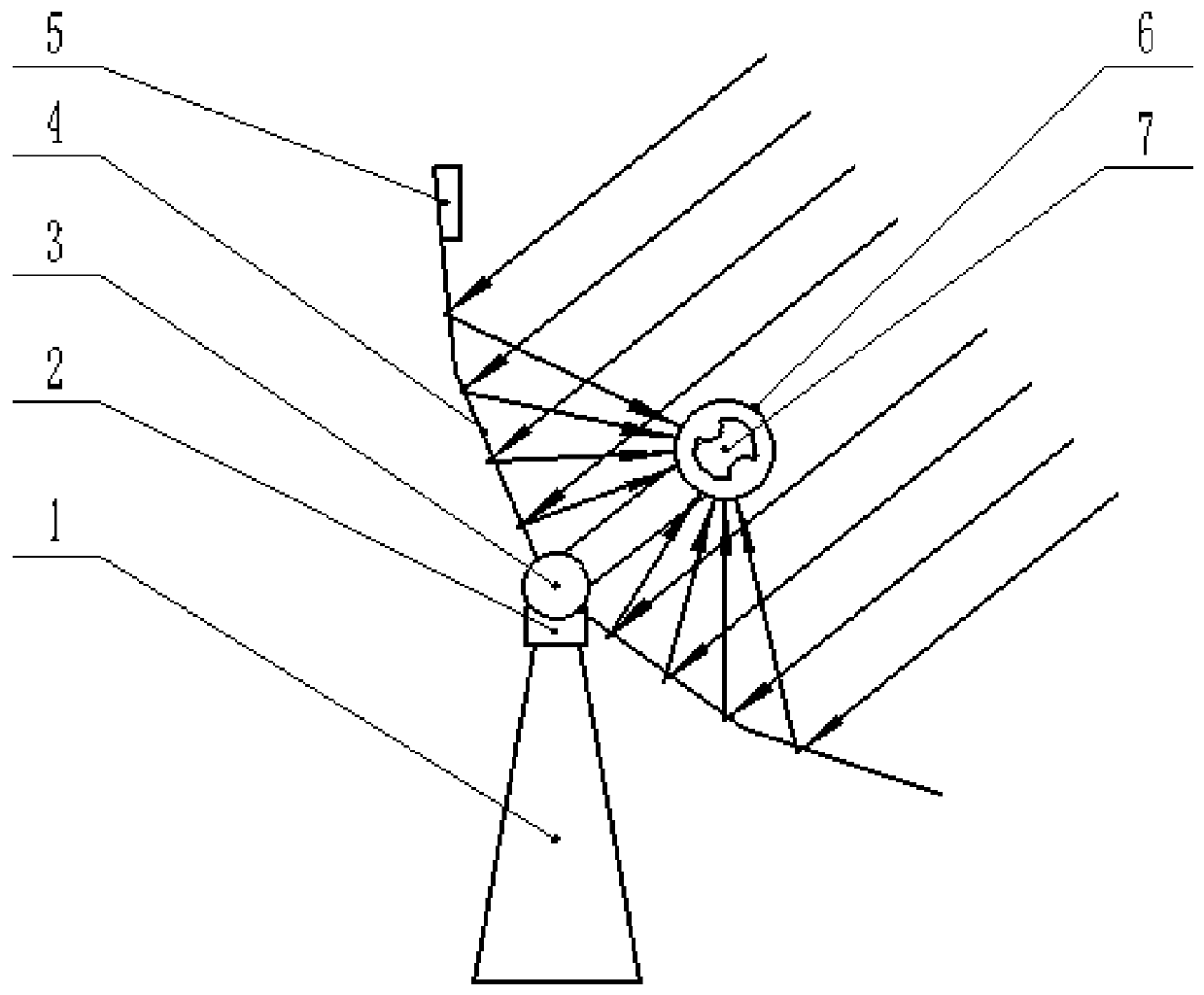

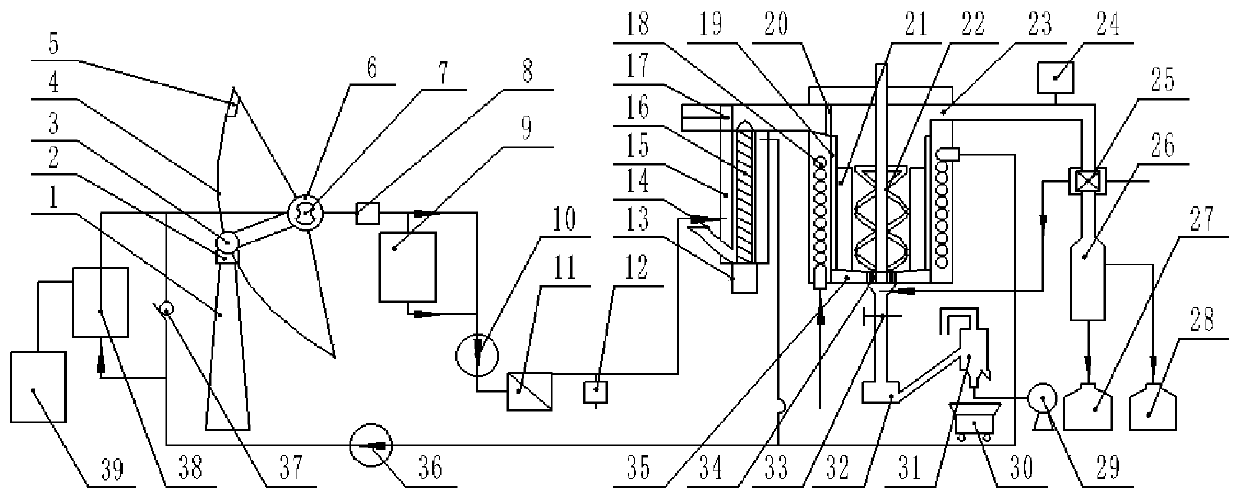

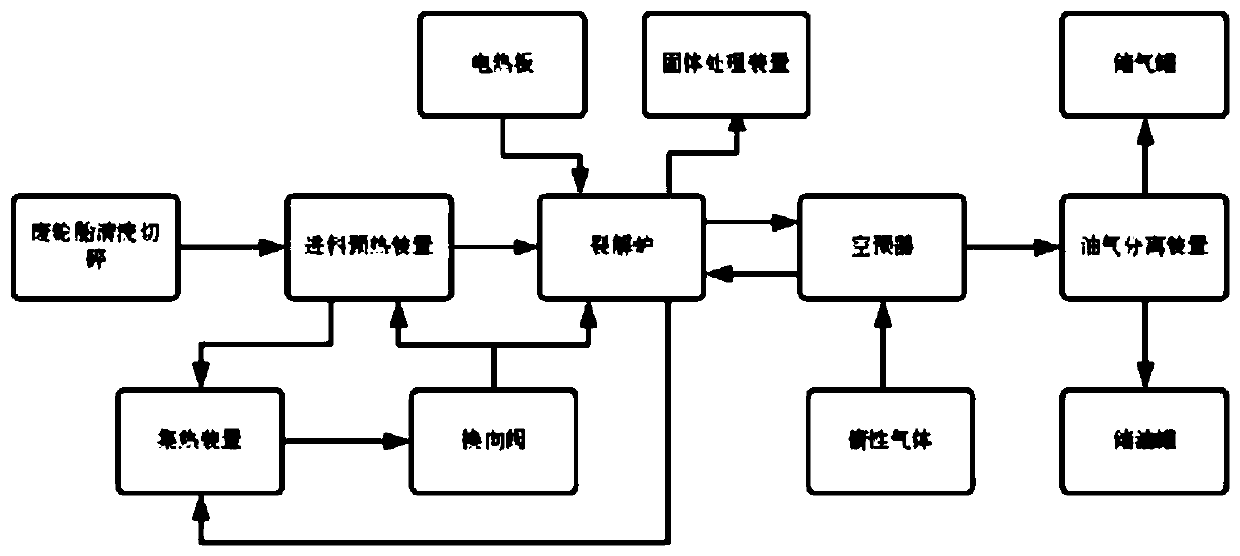

[0032] In an embodiment of the present invention, an equipment for preheating and cracking waste tires based on solar energy includes: a heat collecting device, a feed preheating device, a cracking device, an oil and gas separation and storage device, a solid product recovery device and an automatic control system.

[0033] The devices are connected to each other, and the heat collector in the equipment for preheating and cracking waste tires based on solar energy can absorb solar energy to provide the necessary temperature for cracking waste tires;

[0034] The heat collecting device is respectively connected with the feed preheating device and the cracking device through a fluid pipeline, and the cracking device is connected with the oil-gas separation and storage device through an oil-gas pipeline. The heat collecting device includes: a plate heat collector, a hot salt storage tank 9 and a cooling The salt storage tank 39, the disc collector is made ...

Embodiment 2

[0047] In an embodiment of the present invention, an equipment for preheating and cracking waste tires based on solar energy includes: a heat collecting device, a feed preheating device, a cracking device, an oil and gas separation and storage device, a solid product recovery device and an automatic control system.

[0048] The devices are connected to each other, and the heat collector in the equipment for preheating and cracking waste tires based on solar energy can absorb solar energy to provide the necessary temperature for cracking waste tires;

[0049] The feed preheating device includes a hopper 14, a shell-and-tube heat exchanger 15, a screw feeder and a pusher device, and the tube bundles of the shell-and-tube heat exchanger 15 are parallel to the central axis of the screw and are evenly distributed on the sides of the screw feeder. Inside the outer wall; the pushing device is located on the upper left of the screw feeder, including a pushing block 17 and a transmissio...

Embodiment 3

[0061] In an embodiment of the present invention, an equipment for preheating and cracking waste tires based on solar energy includes: a heat collecting device, a feed preheating device, a cracking device, an oil and gas separation and storage device, a solid product recovery device and an automatic control system.

[0062] The devices are connected to each other, and the heat collector in the equipment for preheating and cracking waste tires based on solar energy can absorb solar energy to provide the necessary temperature for cracking waste tires;

[0063] The feed preheating device includes a hopper 14, a shell-and-tube heat exchanger 15, a screw feeder and a pusher device, and the tube bundles of the shell-and-tube heat exchanger 15 are parallel to the central axis of the screw and are evenly distributed on the sides of the screw feeder. Inside the outer wall; the pushing device is located on the upper left of the screw feeder, including a pushing block 17 and a transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com