Carbon dioxide-based cationic waterborne polyurethane grafted polyacrylate dispersion and preparation method thereof

A water-based polyurethane and polyacrylate technology, applied in the field of polymer materials, can solve problems such as poor mechanical properties, achieve excellent mechanical properties, and avoid the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] According to the method disclosed in the patent 201210086834.X, a poly(carbonate-ether) glycol with a number average molecular weight of 2100 g / mol and a carbonate unit content of 50% was prepared.

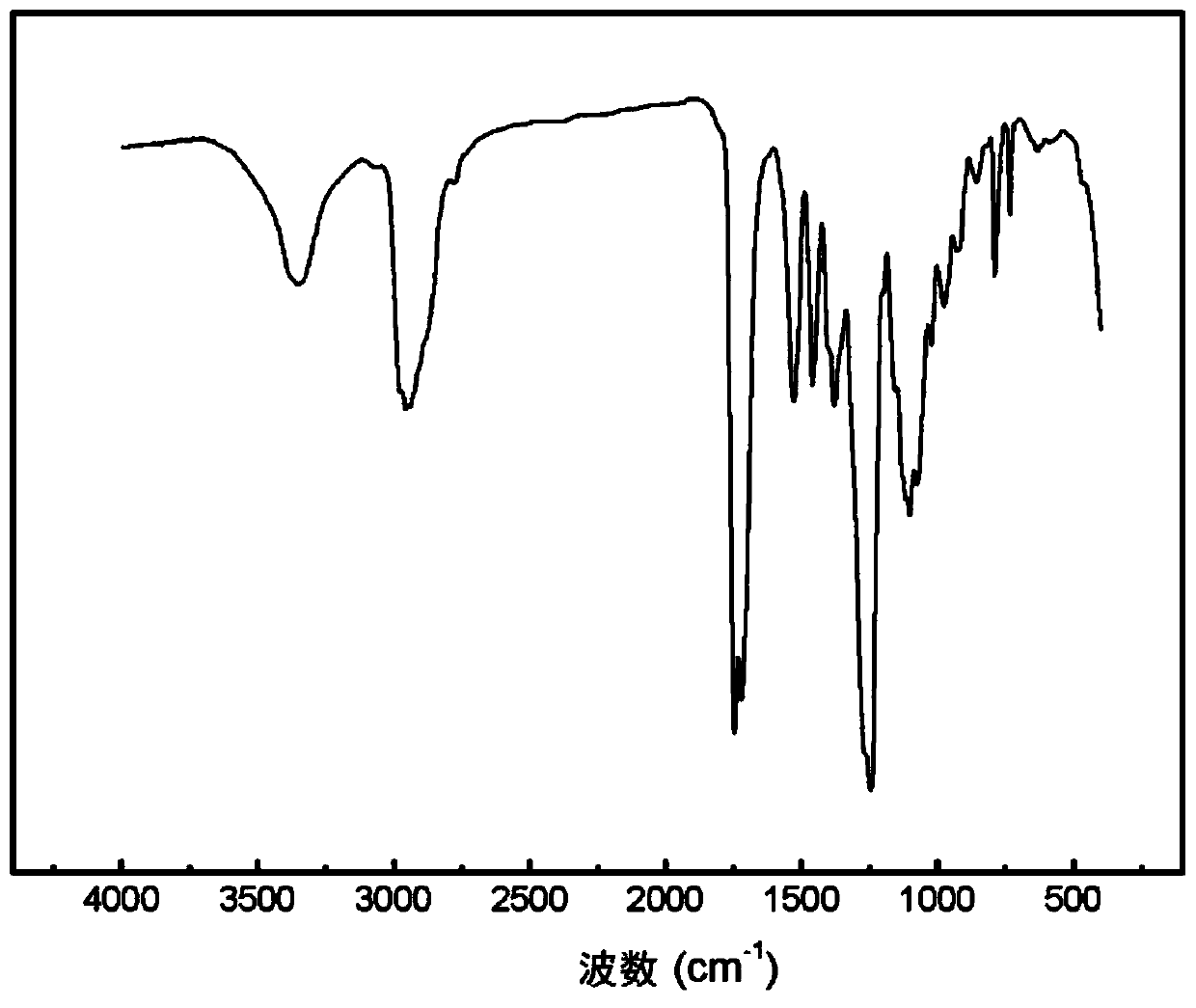

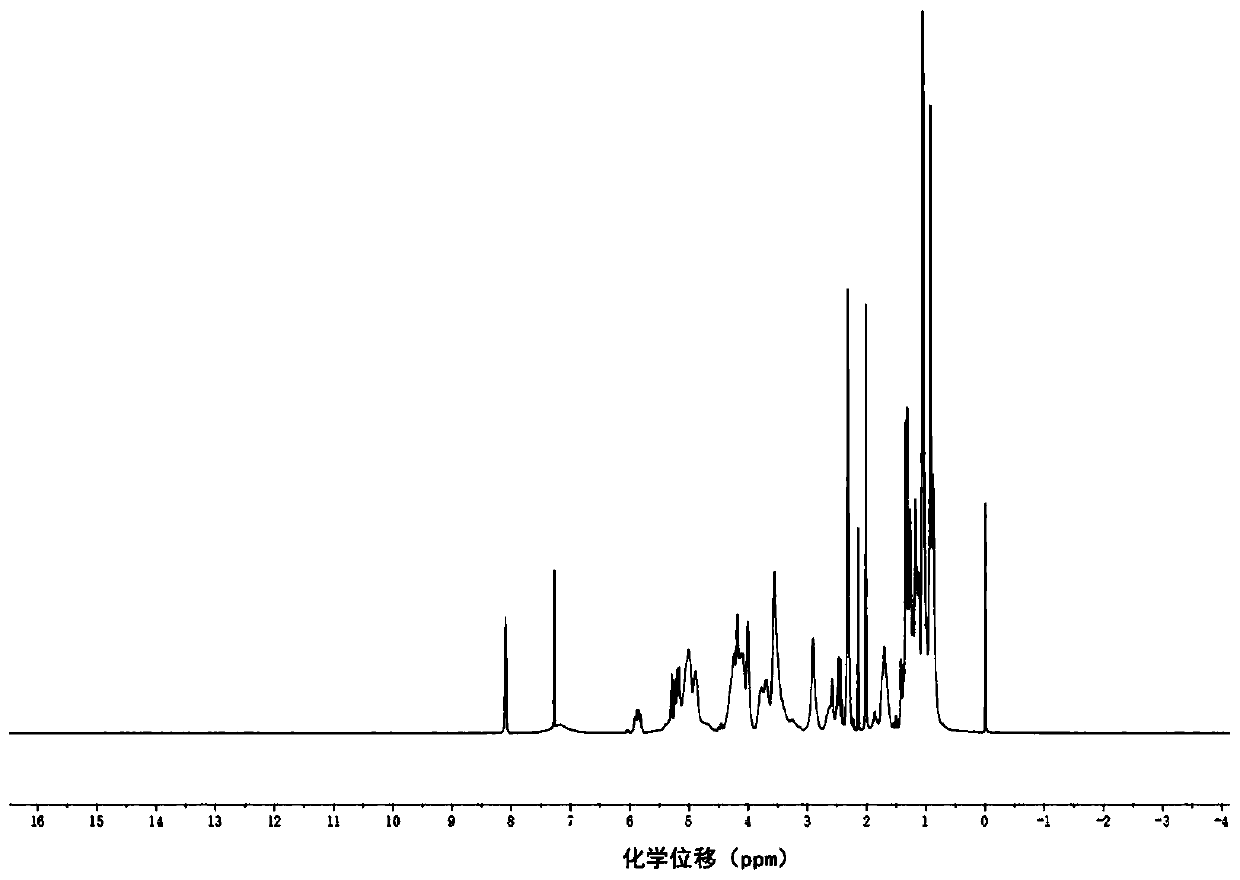

[0059]Add 100 grams of poly(carbonate-ether) glycol prepared by the above method to a three-necked flask, heat to 100°C, dehydrate at -0.98MPa for 1 hour, cool to 70°C, and add 44 grams of iso Phorone diisocyanate, 5.0 grams of butanediol, 1.7 grams of 3-allyloxy-1,2-propanediol, 0.05 grams of dibutyltin dilaurate and 20 grams of butyl acrylate were reacted for 3 hours, then at 75 ° C Add 10 grams of 3-dimethylamino-1,2-propanediol, 0.1 grams of dibutyltin dilaurate and 145 grams of butyl acrylate, react for 3 hours, cool down to 30°C, add 5.0 grams of acetic acid, and react for 2 hours, Add 200 grams of deionized water then, stir 2 hours at 1800rpm, promptly obtain a kind of cationic waterborne polyurethane resin (infrared spectrogram and nuclear magnetic spectrogram see ...

Embodiment 2

[0061] According to the method disclosed in the patent 201210086834.X, a poly(carbonate-ether) glycol with a number average molecular weight of 2100 g / mol and a carbonate unit content of 50% was prepared.

[0062] Add 100 grams of poly(carbonate-ether) glycol prepared by the above method to a three-necked flask, heat to 100°C, dehydrate at -0.98MPa for 1 hour, cool to 70°C, and add 44 grams of iso Phorone diisocyanate, 2.7 grams of butanediol, 5.0 grams of 3-allyloxy-1,2-propanediol, 0.05 grams of dibutyltin dilaurate and 20 grams of butyl acrylate were reacted for 3 hours, then at 75 ° C Add 10 grams of 3-dimethylamino-1,2-propanediol, 0.1 grams of dibutyltin dilaurate catalyst and 145 grams of butyl acrylate, react for 3 hours, cool down to 30°C, add 5.0 grams of acetic acid, and react for 2 hours , then add 200 grams of deionized water, and stir at 1800 rpm for 2 hours to obtain a cationic waterborne polyurethane resin. Subsequently, 1.5 g of azobisisobutylcyanide was adde...

Embodiment 3

[0064] According to the method disclosed in the patent 201210086834.X, a poly(carbonate-ether) glycol with a number average molecular weight of 2100 g / mol and a carbonate unit content of 50% was prepared.

[0065] Add 100 grams of poly(carbonate-ether) glycol prepared by the above method to a three-necked flask, heat to 100°C, dehydrate at -0.98MPa for 1 hour, cool to 70°C, and add 44 grams of iso Phorone diisocyanate, 0.5 g of butanediol, 8.3 g of 3-allyloxy-1,2-propanediol, 0.05 g of dibutyltin dilaurate and 20 g of butyl acrylate were reacted for 3 hours, then at 75°C Add 10 grams of 3-dimethylamino-1,2-propanediol, 0.1 grams of dibutyltin dilaurate catalyst and 145 grams of butyl acrylate, react for 3 hours, cool down to 30°C, add 5.0 grams of acetic acid, and react for 2 hours , then add 200 grams of deionized water, and stir at 1800 rpm for 2 hours to obtain a cationic waterborne polyurethane resin. Subsequently, 1.5 g of azobisisobutylcyanide was added and reacted at 8...

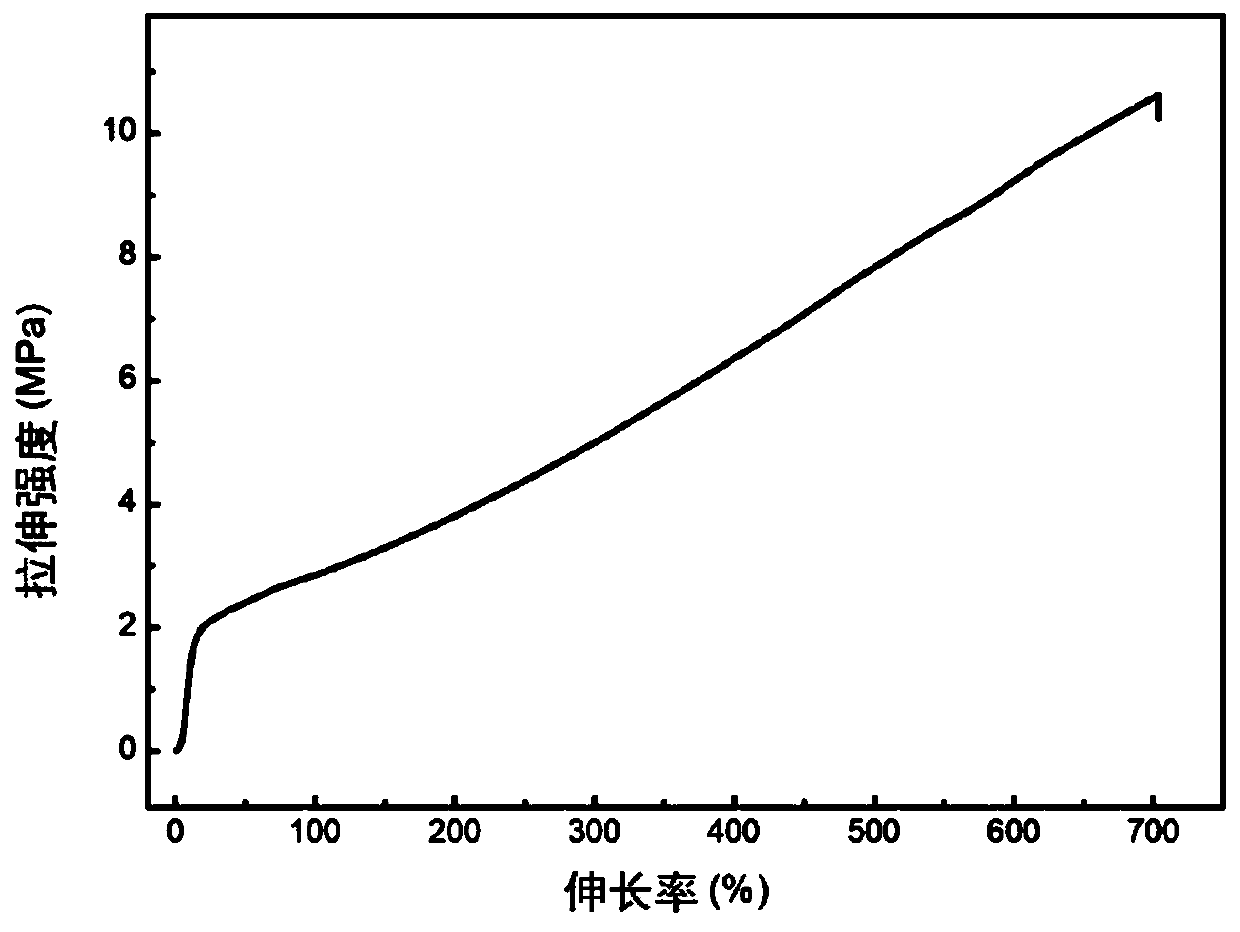

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com