Method for preparing titanium-boron laminar composite efficiently

A layered composite material, titanium boron technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problem of low utilization rate of boronizing agent, save boronizing time and increase fracture toughness , the effect of promoting chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: The part to be infiltrated in this embodiment is a TA2 industrial pure titanium substrate;

[0037] A method for efficiently preparing a titanium-boron layered composite material, the specific steps are as follows:

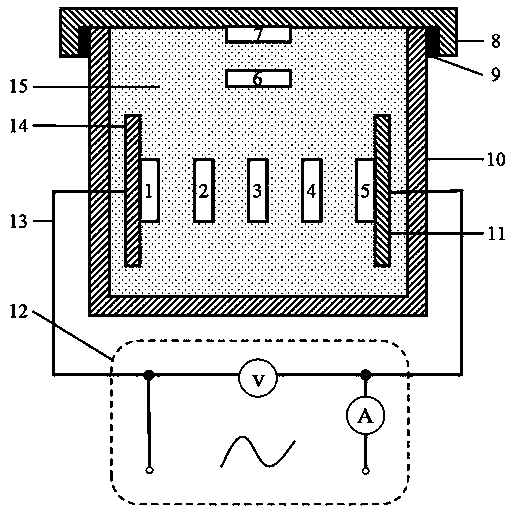

[0038] (1) Install opposite parallel electrodes on the inner wall of the infiltration tank, and the parallel electrodes are externally connected to an AC power supply; the AC power supply is 0~220V;

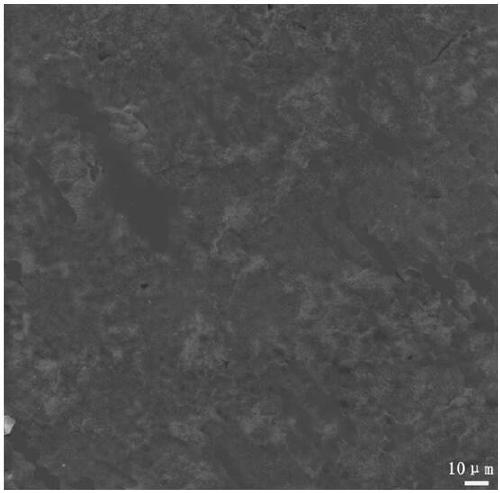

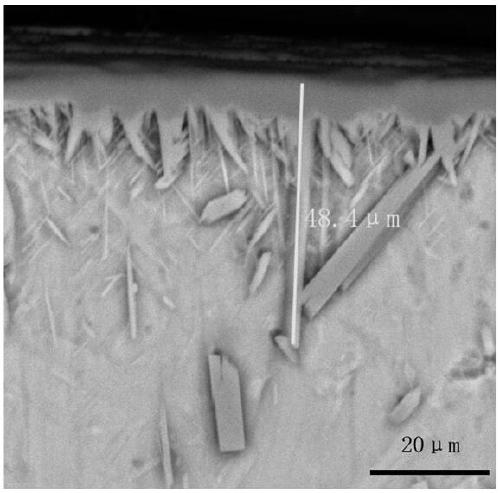

[0039] (2) Add boronizing agent into the infiltration box, then place the pretreated pure titanium between the parallel electrodes in step (1) and parallel to the electrodes, then heat at a uniform speed to a temperature of 800°C, and then conduct constant temperature infiltration with alternating current. After boron treatment for 10 hours, take it out and cool it to room temperature, and boil it in hot water at 90°C for 3 minutes to remove the remaining boronizing agent and impurities on the surface to obtain a titanium-boron layered composite ...

Embodiment 2

[0043] Embodiment 2: the part to be infiltrated in this embodiment is a TB2 titanium alloy substrate;

[0044] A method for efficiently preparing a titanium-boron layered composite material, the specific steps are as follows:

[0045] (1) Install opposite parallel electrodes on the inner wall of the infiltration tank, and the parallel electrodes are externally connected to an AC power supply; the AC power supply is 0~220V;

[0046](2) Add boronizing agent into the infiltration box, and then place the pretreated titanium alloy between the parallel electrodes in step (1) and parallel to the electrodes, then heat at a uniform speed to a temperature of 750°C, and conduct constant temperature infiltration with alternating current. After boron treatment for 5 hours, take it out and cool it to room temperature, and then boil it in hot water at 100°C for 4 minutes to remove boronizing agent and impurities remaining on the surface to obtain a titanium-boron layered composite material; ...

Embodiment 3

[0050] Embodiment 3: The part to be infiltrated in this embodiment is a TC4 titanium alloy substrate;

[0051] A method for efficiently preparing a titanium-boron layered composite material, the specific steps are as follows:

[0052] (1) Install opposite parallel electrodes on the inner wall of the infiltration tank, and the parallel electrodes are externally connected to an AC power supply; the AC power supply is 0~220V;

[0053] (2) Add boronizing agent into the infiltration box, and then place the pretreated titanium alloy between the parallel electrodes in step (1) and parallel to the electrodes, then heat at a uniform speed to a temperature of 850°C, and conduct constant temperature infiltration with alternating current. After boron treatment for 15 hours, take it out and cool it to room temperature, and then boil it in hot water at a temperature of 95°C for 5 minutes to remove the remaining boronizing agent and impurities on the surface to obtain a titanium-boron layere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com