Low-voltage optical axis rotor, steam turbine and low-voltage optical axis rotor restructuring method

A low-pressure rotor and steam turbine technology, applied in the field of steam turbines, can solve the problems of idle equipment waste, resource waste, and high cost, and achieve the effects of ensuring dynamic balance performance, solving idle waste, and shortening construction periods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

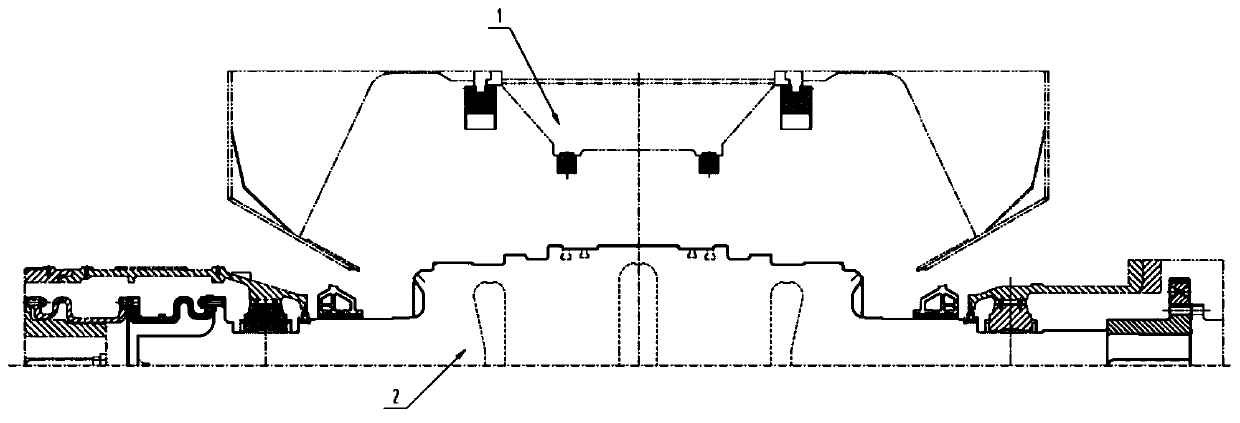

[0045] like Figure 1-6 As shown, the present disclosure provides a low pressure optical axis rotor. figure 1 It is a partial schematic diagram of the low-pressure part of the steam turbine. When the steam turbine is in the second operating state, an optical-axis rotor 2 is installed in the low-pressure cylinder 1 to replace the original bladed rotor. The compressor rotor is connected to the generator rotor and is responsible for transmitting the rotational torque.

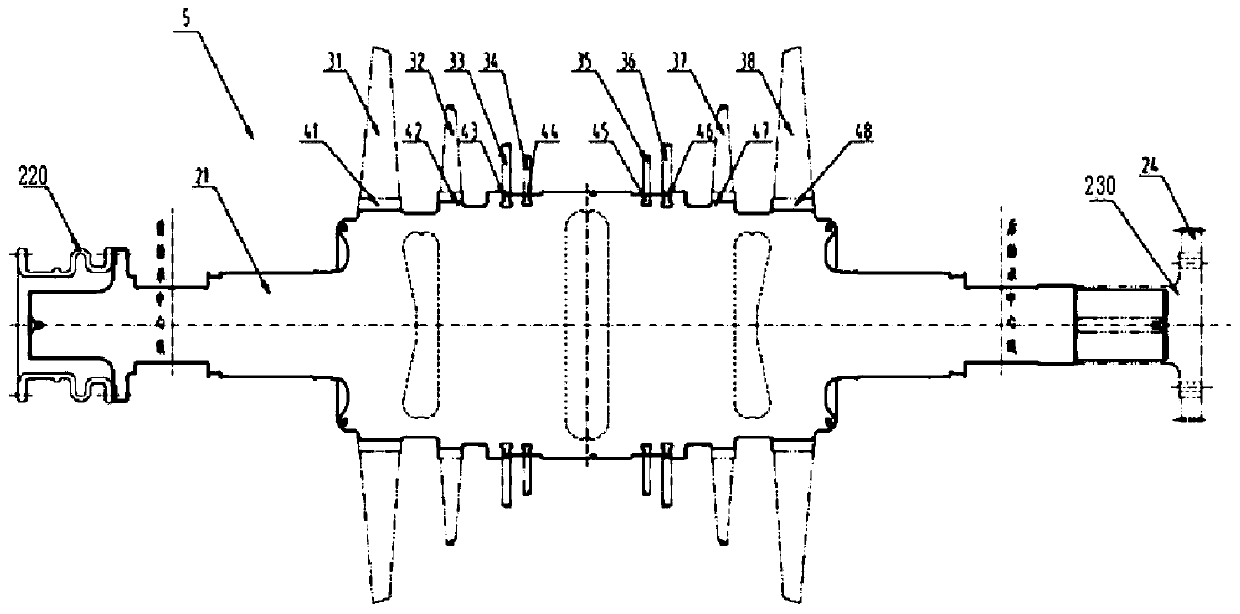

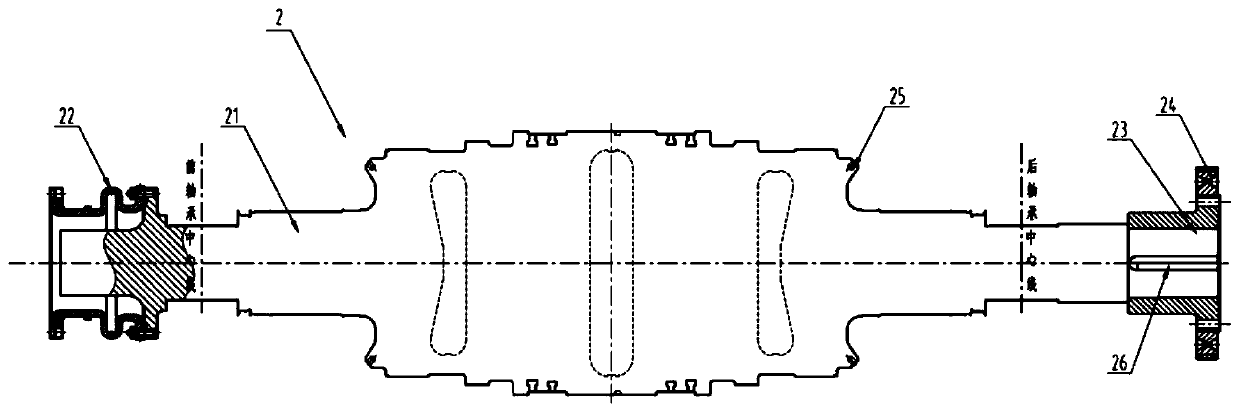

[0046] like figure 2 As shown, the optical axis rotor 2 includes a main shaft 21, a first coupling 22 mounted on the main shaft 21 and a second coupling 23 sleeved on the main shaft; For the interchangeability of some rotors with blades, remove the first coupling 220 of the original rotor 5 on the main shaft 21 , use a lathe to remove the second coupling 230 of the original rotor 5 and remove the turning gear 24 on the original rotor 5 ; With the help of the coupling bolt, the new first coupling 22 is firmly i...

Embodiment 2

[0056] This embodiment provides a steam turbine. The steam turbine has a first operating state in which all steam is used for power generation and a second operating state in which all steam is used for heating. In the first operating state, the low-pressure cylinder A low-pressure rotor with blades is installed, and in the second operating state, a low-pressure optical shaft rotor modified and processed from a low-pressure rotor with blades of the same type is installed in the low-pressure cylinder, characterized in that the optical shaft rotor is The low-voltage optical axis rotor described in Embodiment 1 of the present disclosure, such as Figure 1-6 shown.

Embodiment 3

[0058] The present embodiment: a low-voltage optical axis reforming method is provided, characterized in that the steps are as follows:

[0059] The low-pressure optical shaft rotor for No. 3 unit described in this embodiment is remanufactured from the low-pressure rotor of No. 4 unit decommissioned in Datang Huangdao Power Plant. The flow through transformation was carried out, the rotor, diaphragm, #4 and #5 bearings were replaced by ALSTOM, the jacking oil system was installed, the Baumann stage was cancelled, the deflector and reinforcing ribs of the exhaust cylinder were replaced, and the installation For the low-load water spray device, the last-stage blades of the low-pressure rotor are lengthened from 765mm to 916mm, and the number of low-pressure rotor stages remains unchanged at 2×4. The low-pressure rotor is in the form of a forged welded drum rotor, the low-pressure rotor material is 23CrNiMo747, the low-pressure rotor material brittle transition temperature is -50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com