Film bulk acoustic wave resonator and manufacturing method thereof

A thin-film bulk acoustic wave and manufacturing method technology, applied in electrical components, impedance networks, etc., can solve problems such as unfavorable growth of single crystal piezoelectric materials, easy melting and damage of bottom electrodes, etc., to save manufacturing costs, not easy to melt and damage at high temperature, Yield-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

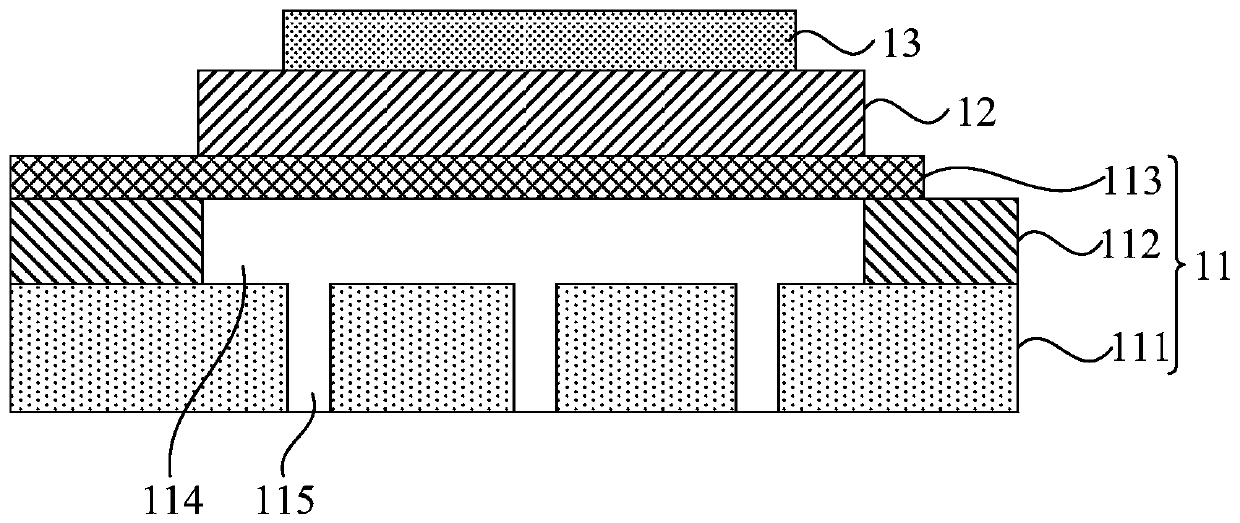

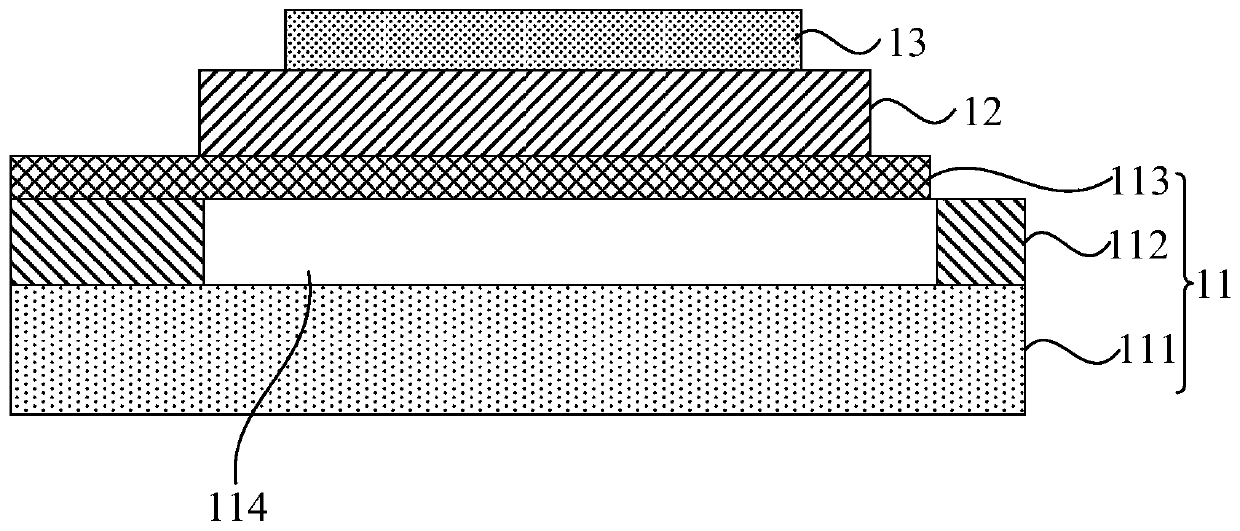

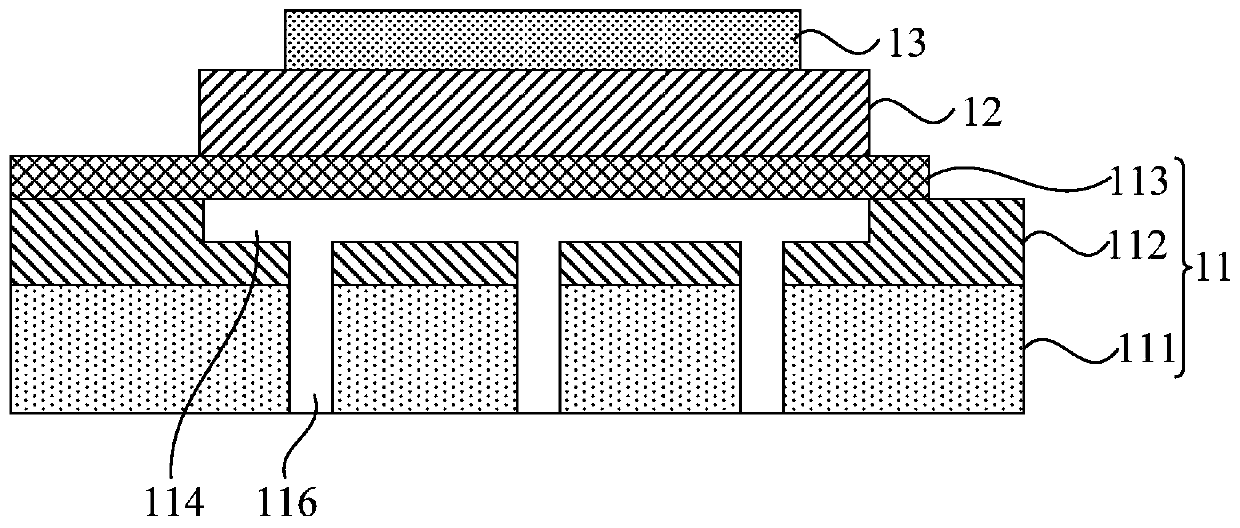

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

[0038] Thin film bulk acoustic resonator is widely used in wireless communication, and its core structure includes top electrode, piezoelectric film layer, and bottom electrode. In the traditional process, after the bottom electrode is formed, a piezoelectric thin film layer is deposited on the bottom electrode, and the material of the piezoelectric thin film layer can be a single crystal piezoelectric material or a polycrystalline piezoelectric material. Single crystal piezoelectric materials are superior to poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com