Electromagnetic wave shielding film

A shielding film, electromagnetic wave technology, applied in the fields of magnetic field/electric field shielding, electrical components, synthetic resin layered products, etc., can solve the problems of large insertion loss, low loss factor of substrates, affecting electromagnetic protection characteristics, etc., and achieves low insertion loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

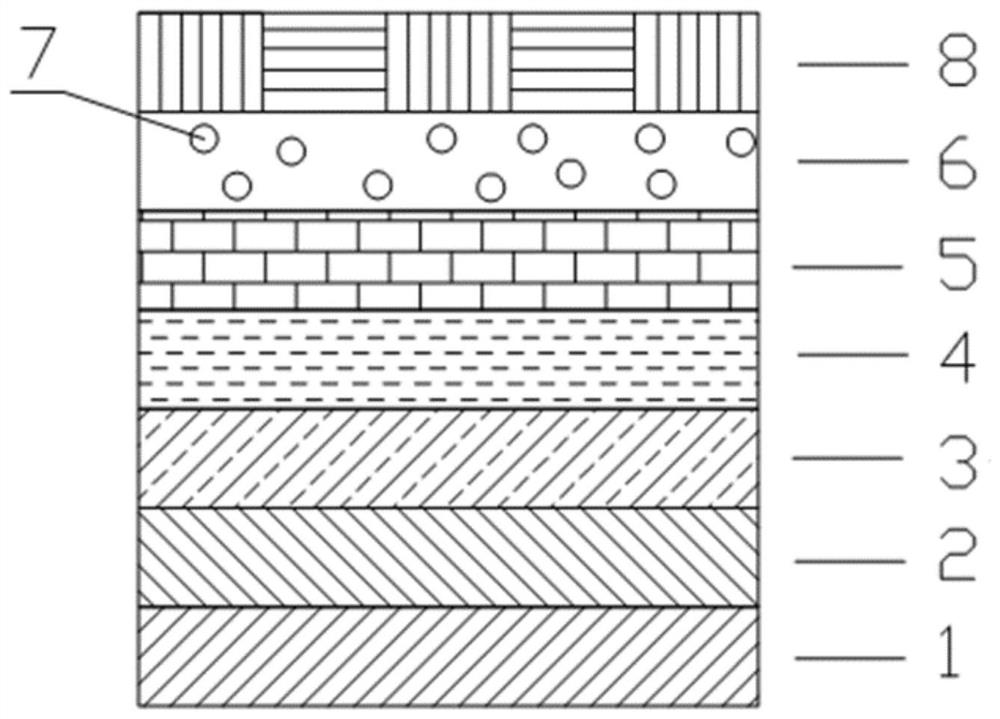

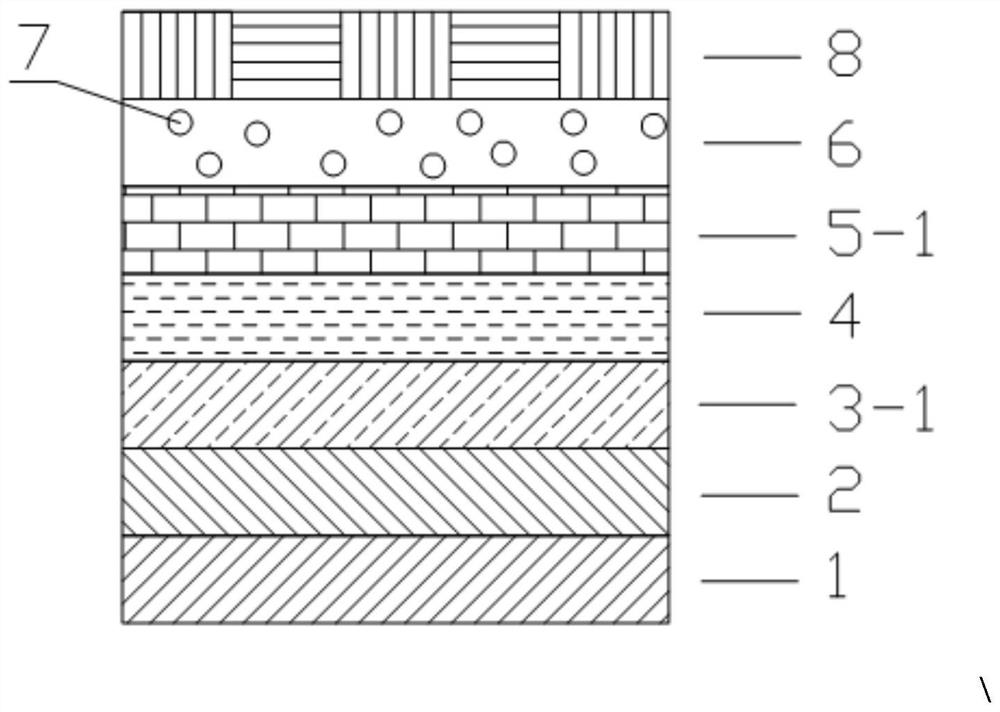

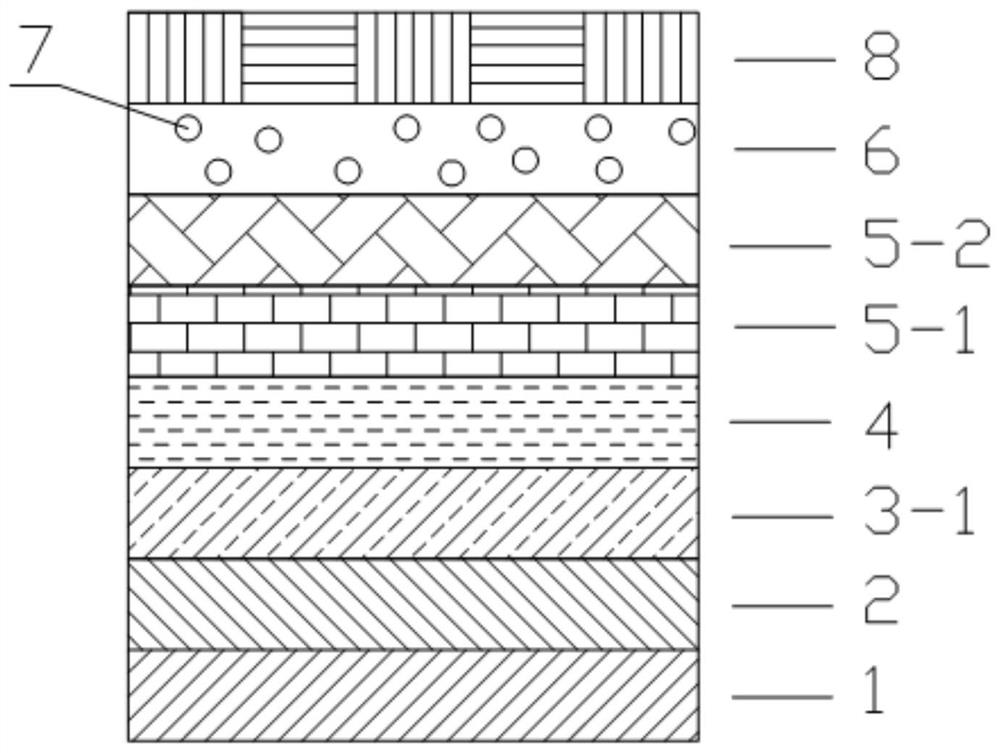

Image

Examples

preparation example Construction

[0073] 1. Preparation of insulating layer 3-1 coating solution

[0074]

[0075] The above-mentioned substances are mixed with a certain proportion of solvents such as tolylbutanone, and then dispersed through known high-speed stirring, ball milling, fast hand, grinding and other processes to form a coating liquid, which is reserved for subsequent coating.

[0076] 2. Preparation of Coating Solution for Glass Fiber Layer 4

[0077]

[0078] The above-mentioned substances are mixed with a certain proportion of solvents such as tolylbutanone, and then dispersed through known high-speed stirring, ball milling, fast hand, grinding and other processes to form a coating liquid, which is reserved for subsequent coating.

[0079] 3. Preparation of conductive adhesive layer 6 coating solution

[0080]

[0081] The above-mentioned substances are mixed with a certain proportion of solvents such as tolylbutanone, and then dispersed through known high-speed stirring, ball milling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com