Compound material sleeve-type filler

A composite material and sleeve technology, used in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of high cost, poor surface wettability, limited liquid gradient flow range, etc. The effect of increasing the rate and facilitating the implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

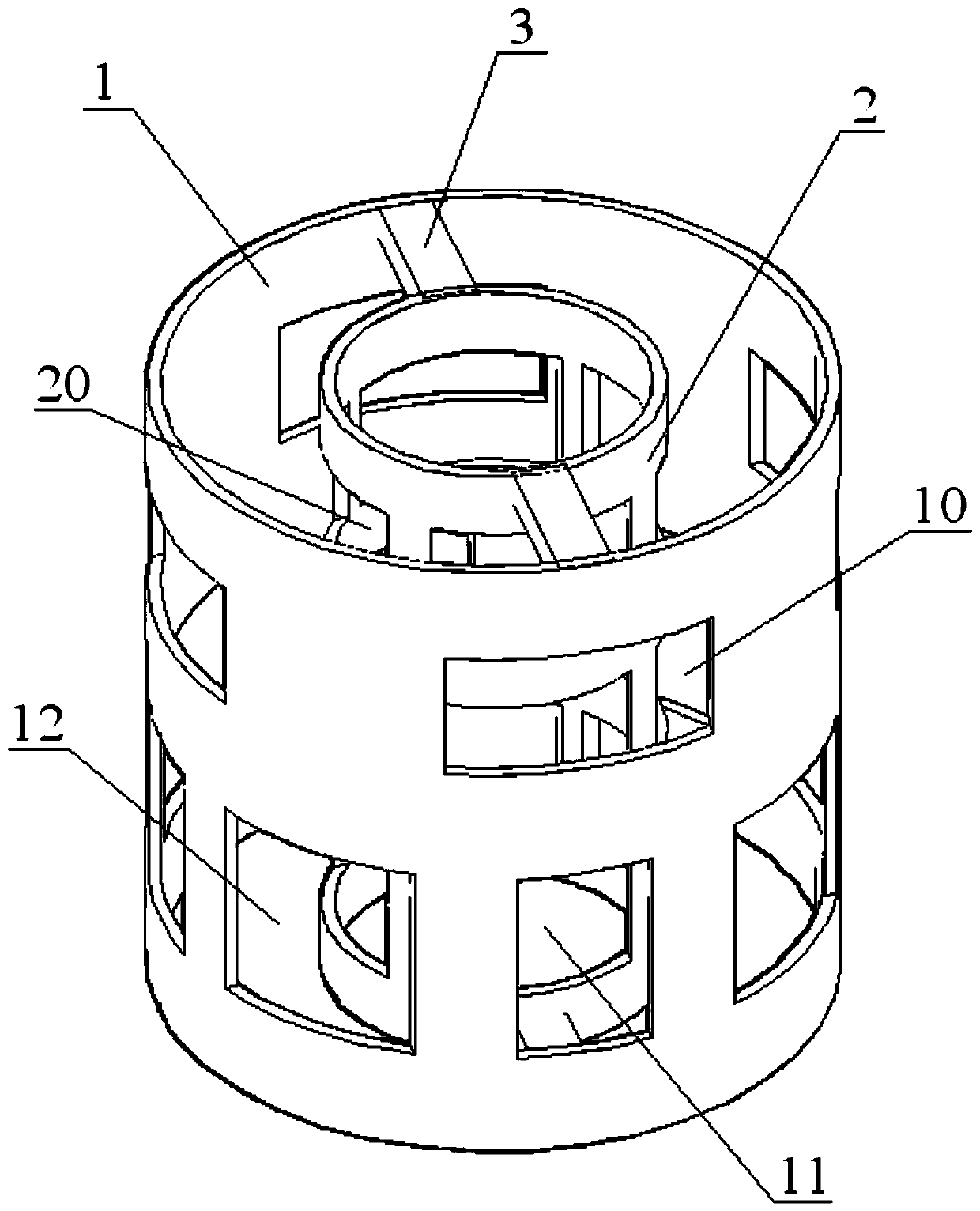

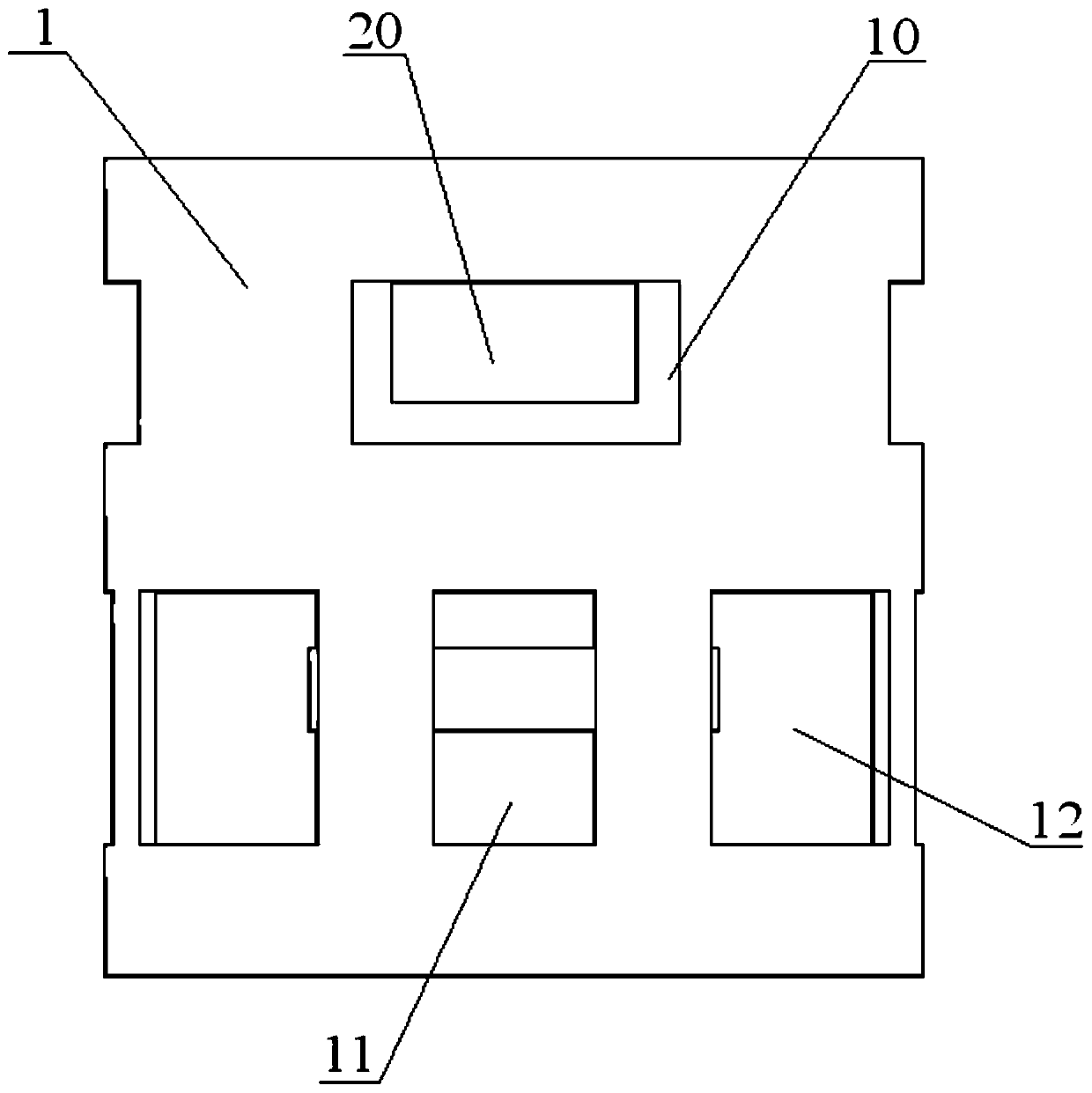

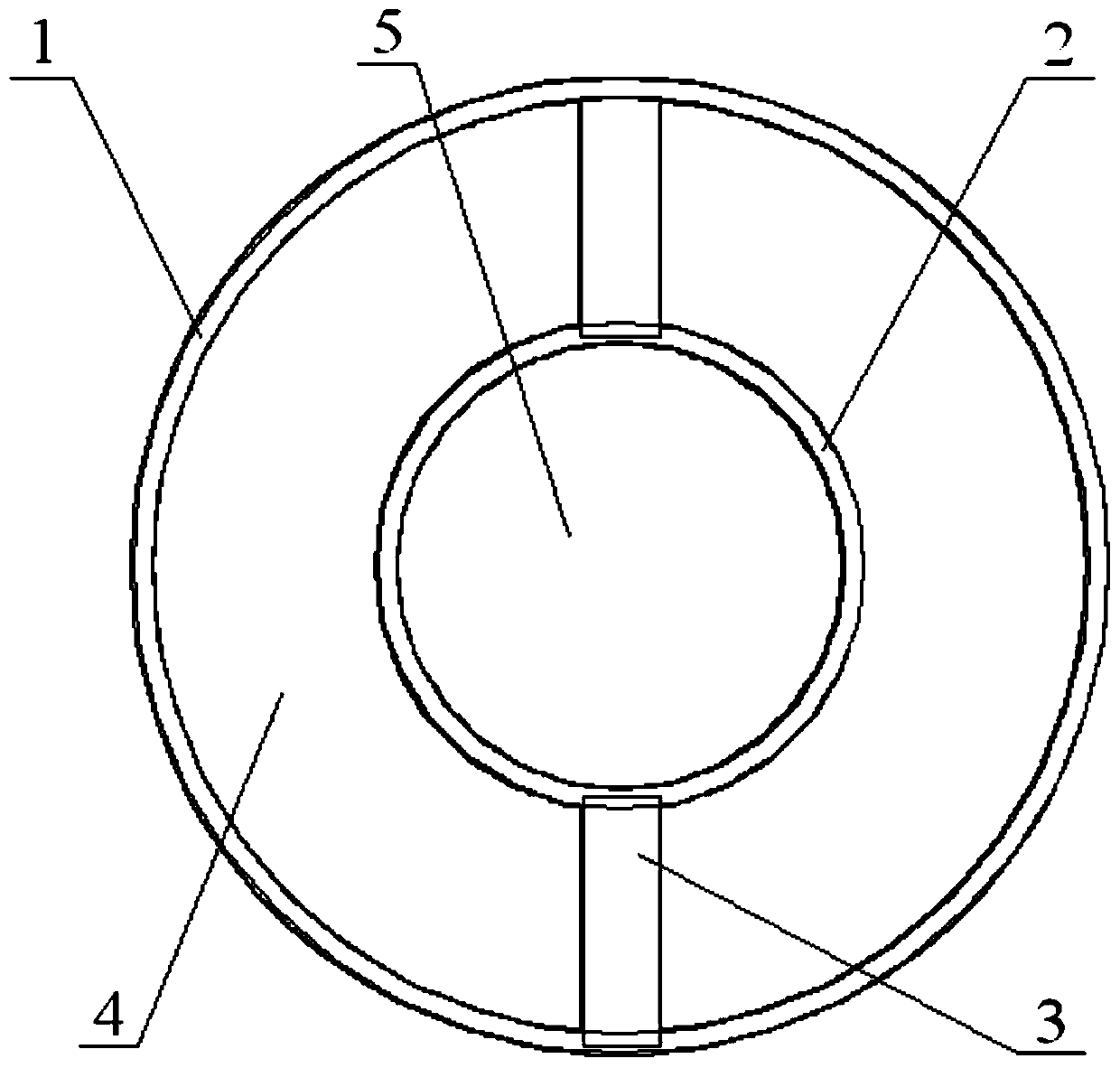

Embodiment 1

[0046] When polyethylene plastic is used as the outer ring body 1 and inner ring body material of this embodiment, the absorption efficiency of the filler is analyzed by the absorption and purification experiment of NOx in the flue gas. The specific content is as follows:

[0047] (1) This embodiment uses laboratory simulated gas as the gas to be processed, the gas flow rate is 450 mL / min, and NO is 280 mg / m 3 , NO 2 The content is 20mg / m 3 , At a constant temperature of 26°C, the gas enters the small ozone oxidation chamber for oxidation reaction, and after the oxidation reaction is completed, the gas is passed into the laboratory small absorption tower;

[0048] (2) The main component of the gas after the previous oxidation reaction is NO 2 , Which also contains a relatively small amount of unoxidized NO. The denitrification efficiency obtained after the spray absorption in the absorption tower is about 93%, and the NOx content in the outlet flue gas is ≤11.7mg / m 3 .

Embodiment 2

[0050] When stainless steel is used as the outer ring body 1 and inner ring body material of this embodiment, the absorption efficiency of the filler is analyzed by the absorption and purification experiment of NOx in the flue gas. The details are as follows:

[0051] (1) This embodiment uses laboratory simulated gas as the gas to be processed, the gas flow rate is 450 mL / min, and NO is 280 mg / m 3 , NO 2 The content is 20mg / m 3 , At a constant temperature of 26°C, the gas enters the small ozone oxidation chamber for oxidation reaction, and after the oxidation reaction is completed, the gas is passed into the laboratory small absorption tower;

[0052] (2) The main component of the gas after the previous oxidation reaction is NO 2 , Which also contains a relatively small amount of unoxidized NO, the denitration efficiency obtained after the absorption tower spray absorption is about 92%, and the NOx content in the outlet flue gas ≤11.9mg / m 3 .

Embodiment 3

[0054] When a stainless steel material is used as the outer ring body 1 of this embodiment, and polyethylene plastic is used as the inner ring body 2 of this embodiment, the absorption efficiency of the filler is analyzed by the absorption and purification experiment of NOx in the flue gas. The details are as follows:

[0055] (1) This embodiment uses laboratory simulated gas as the gas to be processed, the gas flow rate is 450 mL / min, and NO is 280 mg / m 3 , NO 2 The content is 20mg / m 3 At a constant temperature of 26°C, the gas enters the small ozone oxidation chamber for oxidation reaction. After the oxidation reaction is completed, the gas is passed into the laboratory small absorption tower.

[0056] (2) The main component of the gas after the previous oxidation reaction is NO 2 , Which also contains a relatively small amount of unoxidized NO, the denitration efficiency obtained after the absorption tower sprays and absorbs is about 95%, and the NOx content in the outlet flue gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com