Soldering method of radar electronic product connector

A technology of electronic products and brazing methods, which is applied in the field of brazing of radar electronic product connectors, can solve problems such as difficult cleaning, low brazing efficiency, and many connector hole residues, and achieves improved production efficiency, simple operation, Improves hard-to-clean effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A brazing method for a radar electronic product connector comprises the following steps:

[0032] (1) Component cleaning: scrub and clean the component shell and connector of radar electronic products in alcohol for 5 minutes, and air dry naturally;

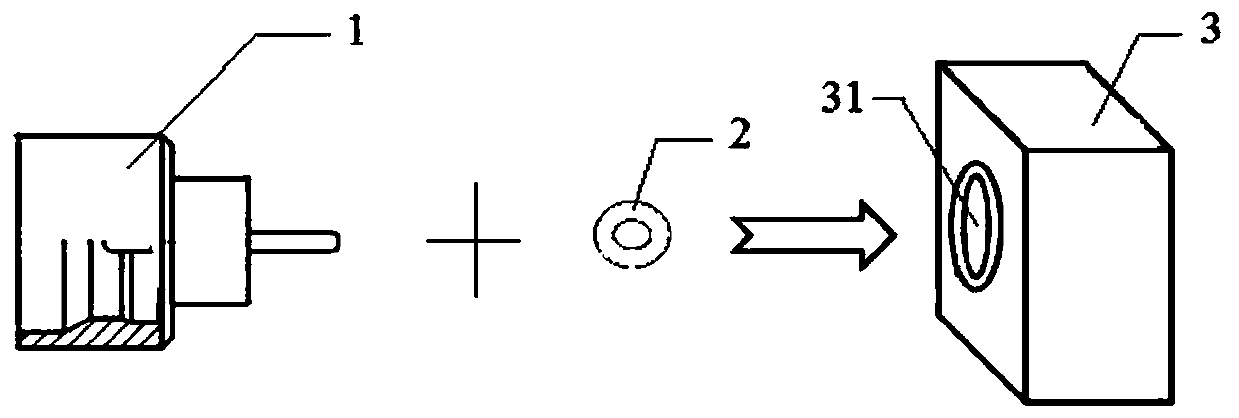

[0033] (2) Assembly: such as figure 1 As shown, put the pre-coated welding ring 2 into the surface of the connector 1 to be welded, put the connector 1 into the connector fitting hole 31 of the component shell 3, and assemble it into a connector module to be welded; The weight of the flux pre-coated on the surface of the ring accounts for 1.5% of the weight of the solder ring; wherein the flux consists of 8wt.% hydrogenated rosin, 0.1wt.% acrylic resin, 3wt.% oxalic acid, rosin glyceride, polyglycerol castor The mixture of hempyl alcohol ester and fatty acid diethanolamide accounts for 2.5wt.% (the mass ratio of the three is 1:1:1), and 86.4wt.% alcohol is mixed; The weight accounts for 1.5% to 3.5% of the weight of the ...

Embodiment 2

[0036] A brazing method for a radar electronic product connector comprises the following steps:

[0037] (1) Component cleaning: scrub and clean the component housing and connectors of radar electronic products in alcohol for 8 minutes, and dry them with an air gun;

[0038] (2) Assembly: such as figure 1 As shown, put the pre-coated welding ring 2 into the surface of the connector 1 to be welded, put the connector 1 into the connector fitting hole 31 of the component shell 3, and assemble it into a connector module to be welded; The weight of the flux pre-coated on the surface of the ring accounts for 2% of the weight of the welding ring; wherein the flux consists of 10wt.% maleic acid modified rosin, 0.2wt.% acrylic resin, 5wt.% malic acid, trihydroxystearic acid The mixture of triglyceride, polyglyceryl ricinoleate and bisstearic acid amide accounts for 2wt.% (the mass ratio of trihydroxystearic acid triglyceride, polyglyceryl ricinoleate and bisstearic acid amide is 1: 2...

Embodiment 3

[0041] A brazing method for a radar electronic product connector comprises the following steps:

[0042] (1) Component cleaning: scrub and clean the component housing and connectors of radar electronic products in alcohol for 8 minutes, and dry them with an air gun;

[0043] (2) Assembly: such as figure 1As shown, use tweezers to put the pre-coated welding ring 2 into the surface of the connector 1 to be welded, put the connector 1 into the connector fitting hole 31 of the component shell 3, and assemble it into a connector module to be welded; The weight of the pre-coated flux on the surface of the coating ring accounts for 3.5% of the weight of the solder ring; wherein the flux consists of 12wt.% acrylic modified rosin and hydrogenated rosin mixture, 0.5wt.% acrylic resin, 5wt.% citric acid, The mixture of glyceryl monostearate, polyglycerol ricinoleate and fatty acid diethanolamide accounts for 2wt.% (the mass ratio of glyceryl monostearate, polyglycerol ricinoleate and fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com