Environment-friendly anti-freezing type concrete and preparation method thereof

A technology of concrete and waste concrete, which is applied in the field of building materials, can solve the problems of reducing the strength of concrete, weakening the bonding force between cement slurry and aggregate and steel bars, and reducing the durability of concrete, so as to improve the compressive strength, promote environmental protection, The effect of mitigating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

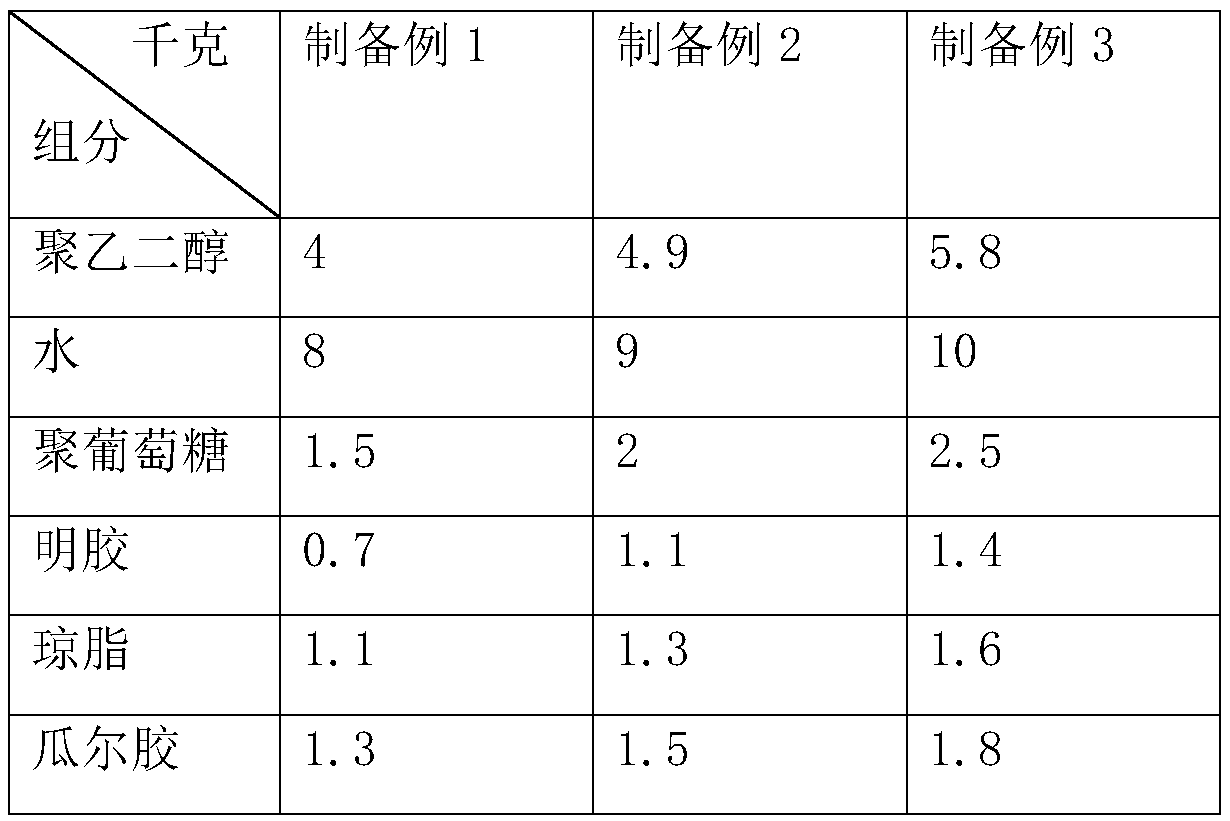

[0037] In the preparation example 1-3, polyethylene glycol is selected from the polyethylene glycol of the model PEG-1000 sold by Foshan Dezhong Chemical Technology Co., Ltd., and the gelatin is selected from the product number sold by Fucheng County Yunhai Adhesive Trade Co., Ltd. The gelatin of 1203, the agar was selected from the agar with item number 125 sold by Henan Xingyuan Chemical Products Co., Ltd., and the guar gum was selected from the guar gum with the model GP-J401 sold by Shandong Guangpu Biotechnology Co., Ltd.

preparation example 1

[0038] Preparation Example 1: According to the ratio in Table 1, heat 8kg of water to 40°C, add 4kg of polyethylene glycol, stir evenly, and add 0.7kg of gelatin under stirring until completely dissolved, then add 1.1kg of agar, After stirring until completely dissolved, add 1.3kg of guar gum and 1.5kg of polydextrose, and cool to room temperature after completely dissolving.

[0039] The raw material ratio of antifreeze in table 1 preparation example 1-3

[0040]

preparation example 2

[0041] Preparation Example 2: According to the ratio in Table 1, heat 9kg of water to 45°C, add 4.9kg of polyethylene glycol, stir evenly, and add 1.1kg of gelatin under stirring until it is completely dissolved, then add 1.3kg of agar , after stirring until completely dissolved, add 1.5kg of guar gum and 2kg of polydextrose, and after completely dissolving, cool to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com