Synthesis and application of copper indium sulfur ternary quantum dots with thioglycerol as ligand

A technology of ternary quantum dots and thioglycerol, applied in the field of biochemistry, can solve the problems of heavy metal toxicity and limited application, and achieve the effects of short synthesis time, reduced toxicity and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

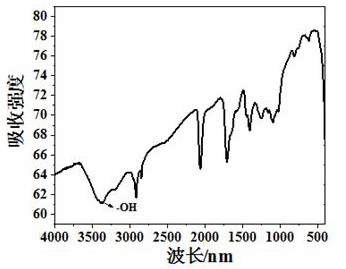

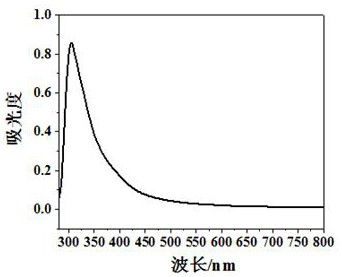

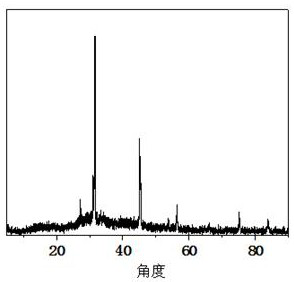

Embodiment 1

[0020] Dissolve 3.60 mmol thioglycerol in a three-necked flask filled with 10.5 mL distilled water, and add CuCl 2 2H 2 O (0.15 mmol) and (0.15 mmol) were added to the mixed solution, and the solution immediately turned light green under nitrogen protection. While stirring, NaOH solution (4mol / L) was added dropwise into the mixed solution with a syringe until the pH value of the mixed solution was adjusted to 10.5, during which the color of the mixed solution changed from light blue to orange-yellow clear liquid. After stirring for 10 min, CS(NH 2 ) 2 (0.30 mmol), and continued to stir for 40 min to obtain a reaction solution; the reaction solution was transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner with a volume of 15 mL. The reaction kettle was placed in an oven at 150°C for 21 h, taken out, and naturally cooled to room temperature to obtain a total of about 15 ml of clear liquid. Add 150 ml of absolute ethanol to the clarified solut...

Embodiment 2

[0030] According to the molar ratio of 1:5:20:40, take CuCl respectively 2 2H 2 O, InCl 3 4H 2 O, thiourea and thioglycerol; dissolve 3.6 mmol thioglycerol in 10.5 mL of distilled water, dissolve thioglycerol in distilled water, add CuCl 2 2H 2 O and InCl 3 4H 2 0, to obtain a mixed solution; under the protection of nitrogen, while stirring, drip the NaOH solution whose molar volume concentration is 4mol / L until the pH value of the mixed solution is 11.0, continue stirring for 15 min, add thiourea rapidly, continue stirring for 50 min, The reaction solution was obtained; the reaction solution was placed in an environment with a temperature of 160°C for 23 h, taken out, and naturally cooled to room temperature to obtain a clear solution; according to the volume ratio of 1:11, the clear solution and absolute ethanol were respectively taken, and the absolute ethanol was added to In the clarified liquid, precipitates were produced, centrifuged three times at high speed, and ...

Embodiment 3

[0032] According to the molar ratio of 1:3:12:25, take CuCl respectively 2 2H 2 O, InCl 3 4H 2 O, thiourea and thioglycerol; dissolve 3.6 mmol thioglycerol in 10.5 mL of distilled water, dissolve thioglycerol in distilled water, add CuCl 2 2H 2 O and InCl 3 4H 2 0, to obtain a mixed solution; under nitrogen protection, while stirring, drip the NaOH solution with a molar volume concentration of 4mol / L until the pH value of the mixed solution is 10.7, continue to stir for 13min, add thiourea quickly, and continue to stir for 45min to obtain a reaction solution; the reaction solution was placed in an environment with a temperature of 155°C for 22 h, taken out, and naturally cooled to room temperature to obtain a clear solution; according to the volume ratio of 1:10.5, the clear solution and absolute ethanol were respectively taken, and absolute ethanol was added to the clear solution In the process, a precipitate was produced, centrifuged at high speed three times, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com