Cement decomposing furnace and method for accelerating mixing of smoke in furnace by using cement decomposing furnace

A cement calcining furnace and flue gas mixing technology, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of reducing the temperature of the calcining furnace, affecting the decomposition of raw meal, etc. Promotes blending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

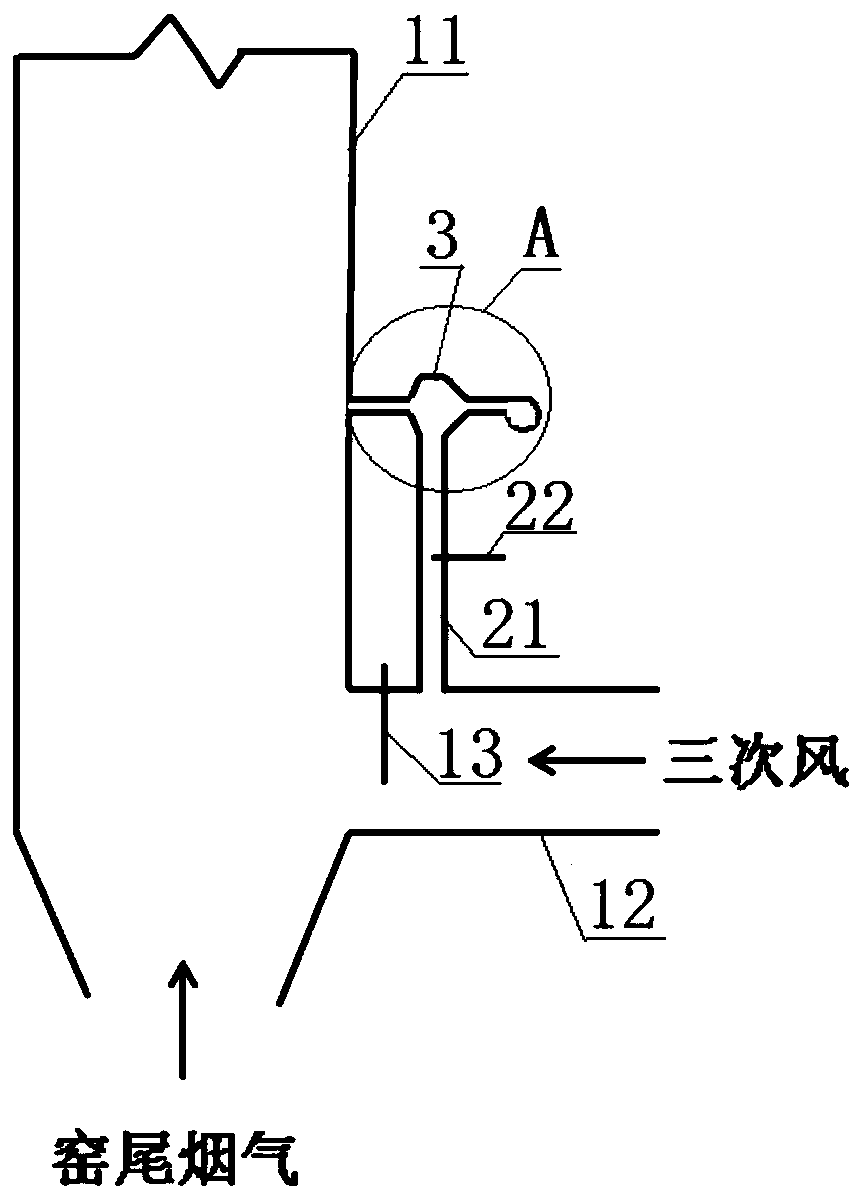

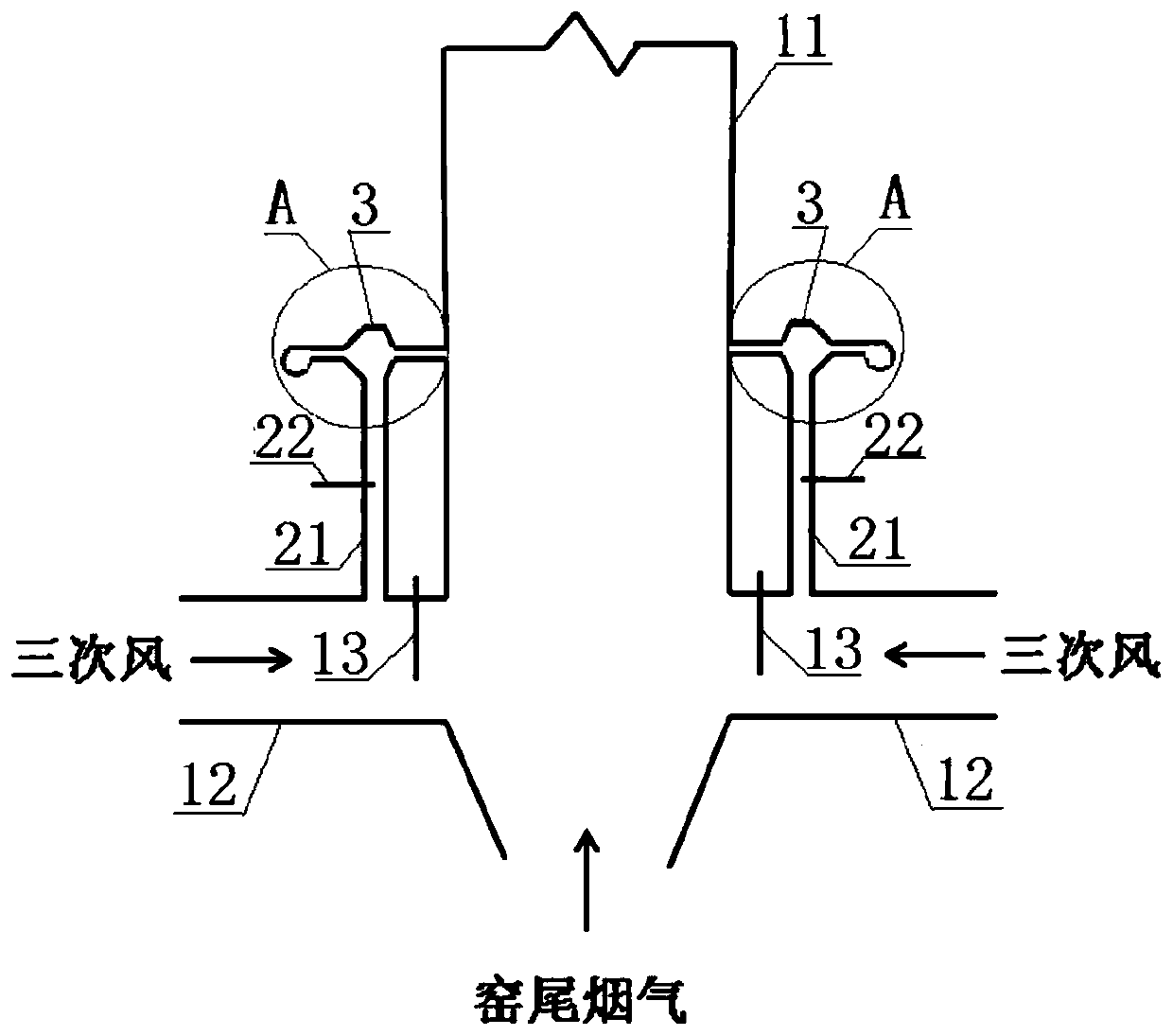

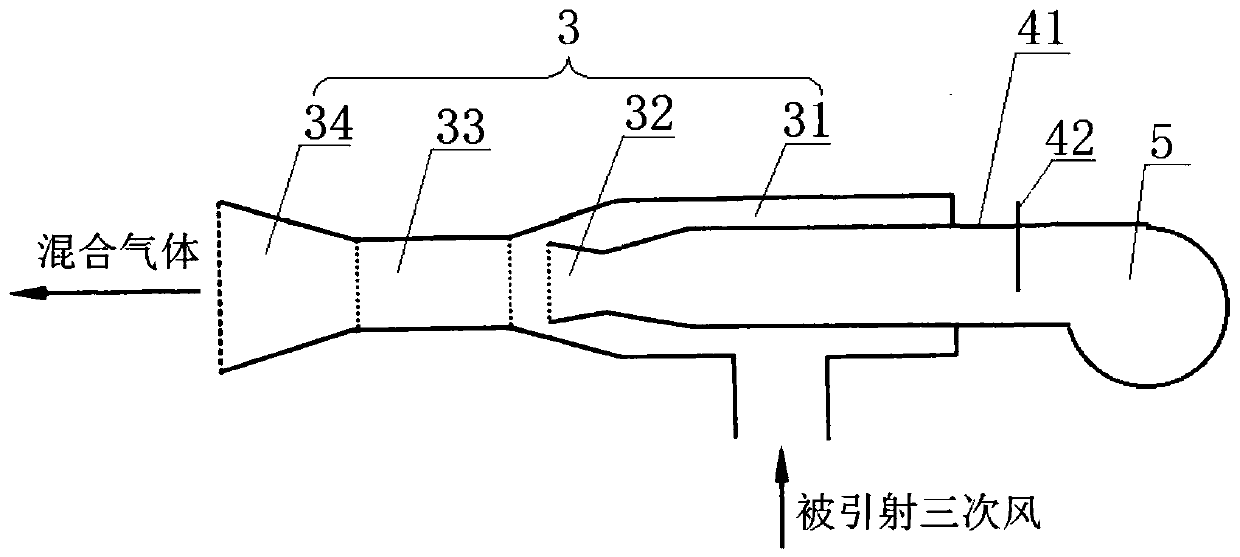

[0087] In this example, a 5000t / d cement production line is taken as an example, and the total air volume for three times is 120000Nm 3 / h, the temperature of the tertiary air is 900°C, the valve opening of the main pipeline is 60%, the outlet temperature of the calciner is 870°C, and the distribution of the ejector system is perpendicular to the flow direction of the flue gas in the calciner. The implementation effect of the present invention has been studied by means of computer CFD simulation, emphatically analyzing the variation of standard deviation and uniformity index of NO component in calciner outlet during different high-pressure cold air flow rates and different flow velocities, as shown in table 1; different injection quantities and injection Schematic diagram of the distribution of NO concentration at the outlet of the calciner at different speeds, such as Figure 4a , Figure 4b , Figure 4c , Figure 4d and Figure 4e shown.

[0088] When the injection amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com