Processing method of lithium ion battery pole

A technology of lithium-ion batteries and processing methods, which is applied in the direction of battery components, battery boxes/coatings, small-sized batteries/batteries, etc., can solve problems such as high cost, low production efficiency, and easy desoldering, and achieve production High efficiency, simplified production process, and not easy to desolder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to allow those skilled in the art to better understand the technical solution of the present invention, the present invention will be further elaborated below.

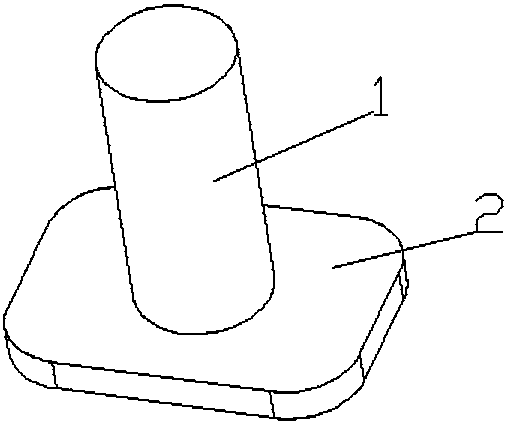

[0021] as attached figure 1 A copper-aluminum composite pole is shown, a copper column 1 and an aluminum plate 2 .

[0022] A method for processing a lithium ion battery pole, specifically comprising the following steps:

[0023] Step 1, prepare the base material: copper column and aluminum plate, process one end of the copper column into a stepped protrusion according to the required size, and process the center position of the aluminum plate shaft into a groove matching the stepped protrusion of the copper column;

[0024] Step 2, electroplating the surface of the stepped convex portion of the copper pillar, the copper pillar electroplating adopts nickel plating, and the thickness of the plating layer is 7.5 um~10 um;

[0025] Step 3, coating a layer of metal brazing material on the protrusion of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com