Radial magnetic field stator yoke-free double-rotor disc type permanent magnet synchronous motor

A permanent magnet synchronous motor and magnetic field stator technology, applied in the field of electromechanical, can solve the problems of stator and rotor rubbing, unsatisfactory, bumpy, vibration, etc., and achieves large equivalent electromagnetic diameter, light weight, peak torque high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

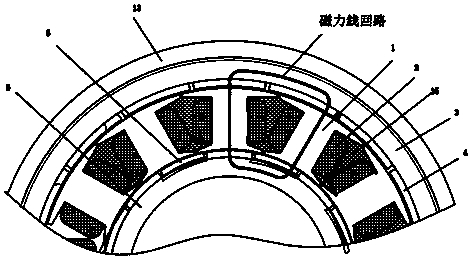

[0023] Such as figure 1 As shown, the radial magnetic field stator yokeless dual-rotor permanent disk motor provided by the present invention includes a stator core 1, a stator winding 2, an outer rotor core 3, an outer magnet 4, an inner rotor core 5, and an inner magnet 6. The rotor bracket 7, the rotating shaft 8, the front bearing 9, the rear bearing 10, the front end cover 11, the rear end cover 12 and the casing 13, the stator core 1, the outer rotor core 3, and the inner rotor core 5 are all made of silicon steel The outer magnetic steel 4 and the inner magnetic steel 5 are made of rare earth permanent magnet materials, the rotor bracket 7 is made of aluminum alloy or carbon steel, the front end cover 11, the rear end cover 12 and The casing 13 is made of aluminum alloy.

[0024] The stator core 1 is fixed with the front end cover 11 by potting epoxy 15 with the stator winding 2 through the fixed bracket 14; the outer magnetic steel 4 and the inner magnetic steel 6 are...

Embodiment 2

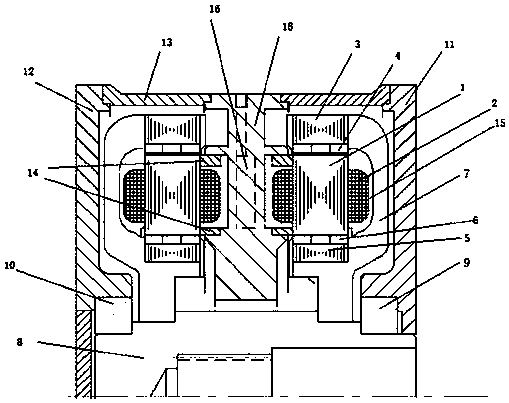

[0026] Such as image 3 As shown, it is an embodiment that combines the above-mentioned embodiment 1 into a double motor. The difference from embodiment 1 is that embodiment 2 is composed of two left and right stators, two outer rotors and two inner rotors; a rotor bracket is used 7 Support and connect the two left and right outer rotors and two inner rotors; the two stator cores 1 are respectively fixed on the front end cover 11 and the rear end cover 12 in the same way as in Embodiment 1; the front end cover 11 and the rear end cover 12 Coolant water channels 16 are opened respectively. All the other are similar to embodiment 1.

Embodiment 3

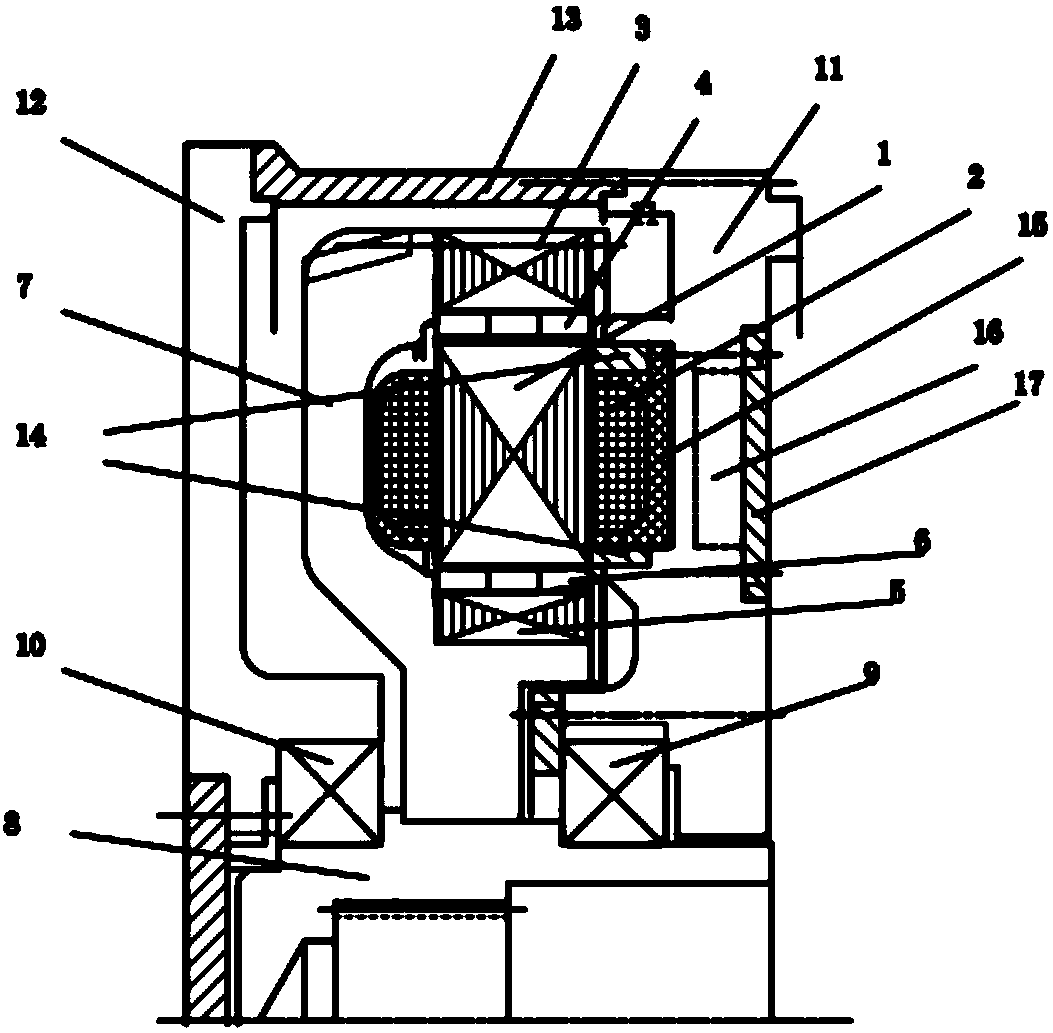

[0028] Such as Figure 4 As shown, it is another embodiment in which the above-mentioned embodiment 1 is combined into a double motor. The difference from embodiment 2 is that embodiment 3 uses a middle stator bracket 18 to fix two left and right stators 1, and two left and right stators The outer rotor and the two inner rotors are respectively supported by two left and right rotor brackets 7 ; a coolant channel 16 is opened on the middle stator bracket 18 . All the other are similar to embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com