Hydrophobic coating, preparation method thereof, application thereof and absorbable implantable device

A hydrophobic coating and implantable technology, applied in the field of absorbable implantable devices and hydrophobic coatings, can solve the problems of difficulty in use, limitation, and reduce the degradation rate of degradable matrix materials, so as to improve porosity and delay degradation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The preparation method of the hydrophobic coating of an embodiment, comprises the steps:

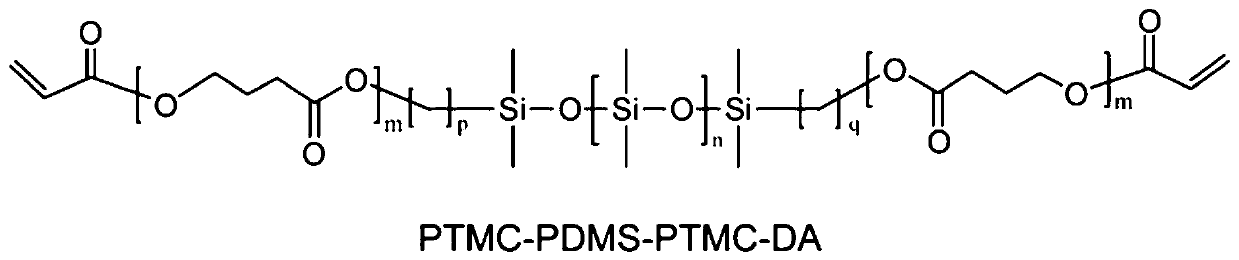

[0069] Step 110: providing a hydrophobic monomer, which is a block copolymer comprising a hydrophobic block, a degradable block and a cross-linking functional group.

[0070] The hydrophobic monomer is the same as above, and will not be repeated here.

[0071] In one embodiment, the following method is used to prepare hydrophobic monomers:

[0072] Use a polymer containing terminal hydroxyl groups to form a hydrophobic block (that is, A-OH, both ends contain hydroxyl groups, the following expressions represent the same meaning, and will not be described in detail below) as an initiator to synthesize a hydrophobic block containing terminal hydroxyl groups And the polymer of the degradable block (ie B-A-B-OH), and then use acryloyl chloride to react with the terminal hydroxyl group of the polymer containing the hydrophobic block and the degradable block at the end to obtain the hyd...

Embodiment 20~ Embodiment 24

[0113] Embodiment 20~embodiment 24 and comparative example 1~comparative example 4 adopt following test method:

[0114] In vivo sample metal weight loss measurement method: the absorbable implantable device is implanted in the animal body for a period of time, and then the animal is sacrificed, and the absorbable implantable device is taken out. Micro-CT with a resolution of 5 μm was used for high-resolution scanning, and the results were processed to calculate the volume of undegraded metal, so as to calculate weight loss=1-volume of undegraded metal / initial metal volume.

[0115] Table 1 Embodiment 1-19 hydrophobic coating components

[0116]

[0117]

Embodiment 1

[0119] Cut a pure iron sheet with a thickness of 200 μm (purity >99.9%) into 22mm×26mm, polish it with 800, 1500, 2000, and 3000 mesh sandpaper in sequence, and put the polished iron sheet in acetone and absolute ethanol for ultrasonic cleaning in sequence 10min, then dry the surface of the iron sheet with nitrogen, and place the iron sheet in an oven at 60°C to fully dry.

[0120] Dissolve polylactic acid (PLA) with a molecular weight of 60,000 in ethyl acetate to prepare a polylactic acid solution with a concentration of 0.01 g / mL. The polylactic acid solution was sprayed on the surface of the treated iron sheet by an ultrasonic spraying method to prepare an iron sheet with a PLA coating on the surface with a thickness of 4 μm. During the spraying process, the flow rate of the pump liquid is 0.1mL / min, and the ultrasonic power is 5.0W. Place the PLA-coated iron sheet in a fume hood to fully evaporate the ethyl acetate solvent.

[0121] With reference to the method in the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com