Improved process for wet detoxification of hexavalent chromium-containing waste residues or hexavalent chromium contaminated soil

A technology of polluting soil and hexavalent chromium, which is applied in the field of pollution control, can solve problems such as difficult stirring, unfavorable reduction of hexavalent chromium, thickening of slurry, etc., to reduce calcium sulfate precipitation, promote full contact, and reduce aging time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

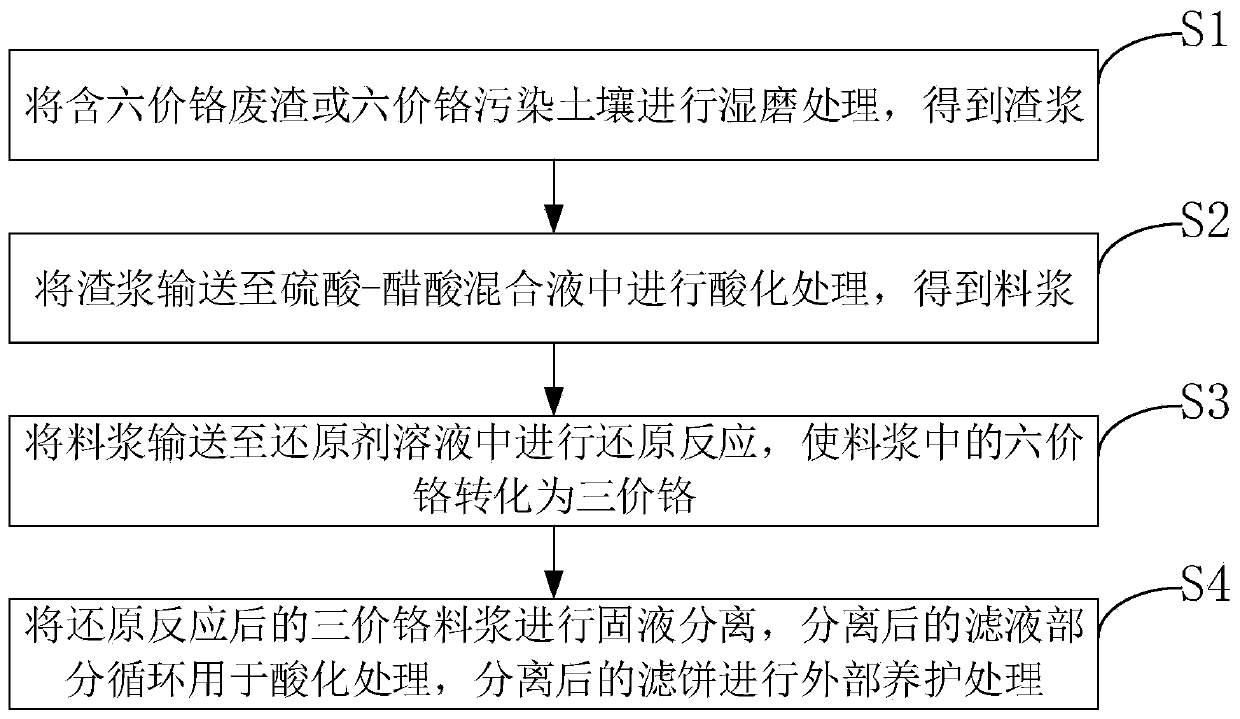

Method used

Image

Examples

Embodiment 1

[0057] The mixture of chromium slag and soil at the original site of a chromium salt production enterprise in Baiyin, Gansu Province, the content of hexavalent chromium is 2000-3000mg / kg.

[0058] S1, put the slag mixture that has been screened and ground into a ball mill for wet grinding, so that it can pass through a 100-mesh sieve;

[0059] S2, first pump the sulfuric acid (10% solution)-acetic acid (5% solution) mixed solution with a volume ratio of 1:1 into the acidification reaction tank, then gradually pump the slurry through the 100 mesh sieve into the acidification reaction tank and acidification reaction tank The solution is mixed and stirred to keep the pH of the slurry in the range of 5-6, and aged for 6 hours;

[0060] S3, gradually pump the slurry after the acidification into the reduction reaction tank and stir and mix it with the reducing agent. The pumping time is 2 hours. The ratio of the aqueous solution of the reducing agent in the reduction reaction tank i...

Embodiment 2

[0065] The mixture of chromium slag and soil at the original site of a chromium salt production enterprise in Zhangye, Gansu has a hexavalent chromium content of 4000-5000mg / kg.

[0066] S1, put the slag mixture that has been screened and ground into a ball mill for wet grinding, so that it can pass through a 150-mesh sieve;

[0067] S2. Pump the sulfuric acid (20% solution)-acetic acid (10% solution) mixture with a volume ratio of 3:1 into the acidification reaction tank, and then gradually pump the slurry passing through the 150 mesh sieve into the acidification reaction tank to mix with the acid solution Stir to keep the pH of the slurry in the range of 5-6, and age for 6 hours;

[0068] S3, gradually pump the slurry after the acidification into the reduction reaction tank and stir and mix it with the reducing agent. The pumping time is 2 hours. The ratio of the aqueous solution of the reducing agent in the reduction reaction tank is as follows: the molar ratio of ferrous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com