A kind of paper tray and its processing technology

A processing technology and pallet technology, used in papermaking, paper/cardboard containers, packaging, etc., can solve problems such as deformation and separation, and achieve the effects of improving structural strength, improving use stability, and shortening production and processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

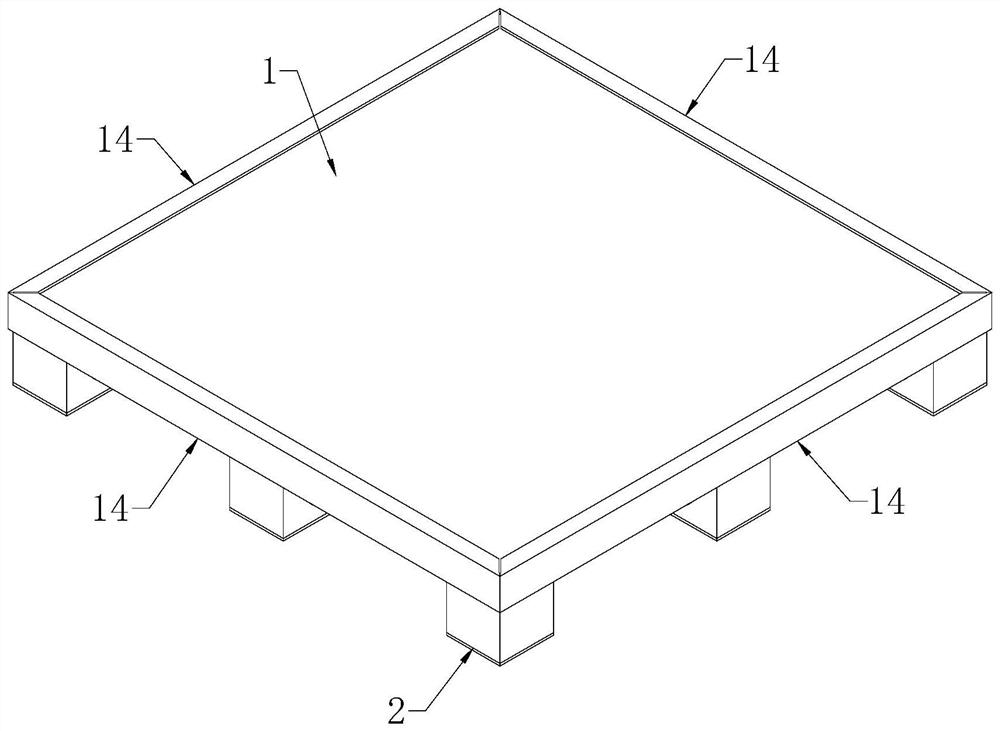

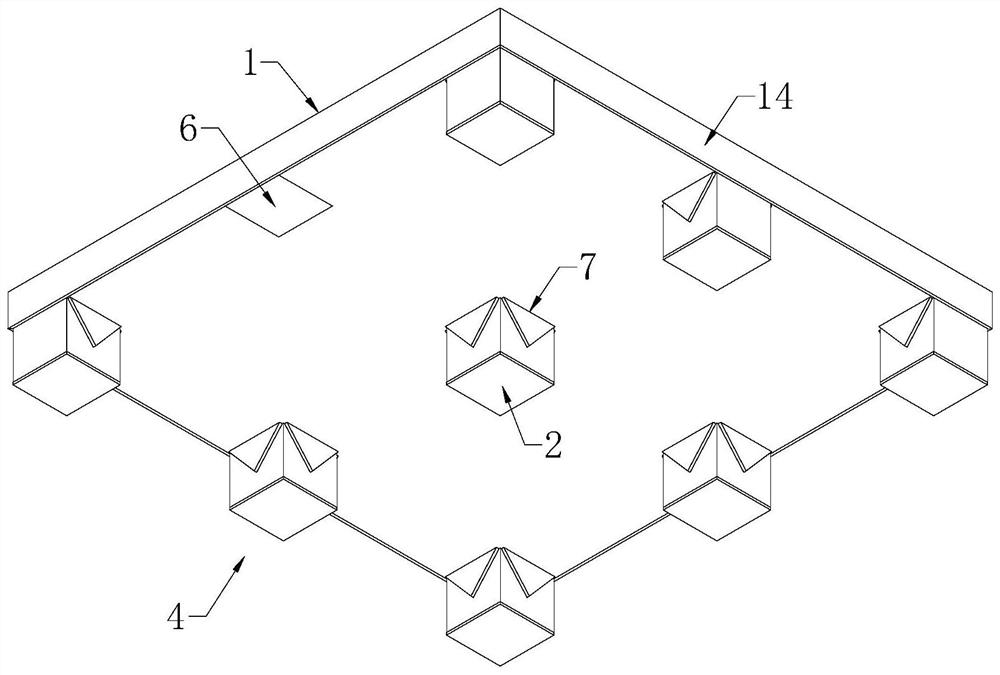

[0039] combine figure 1 and figure 2As shown, a paper pallet includes a pallet body 1 for carrying a load unit. The pallet body 1 is arranged horizontally, and the bottom of the pallet body 1 is evenly arranged with a plurality of feet 2. The feet 2 can evenly transmit the load and The role of stably supporting the pallet body 1 and the load unit.

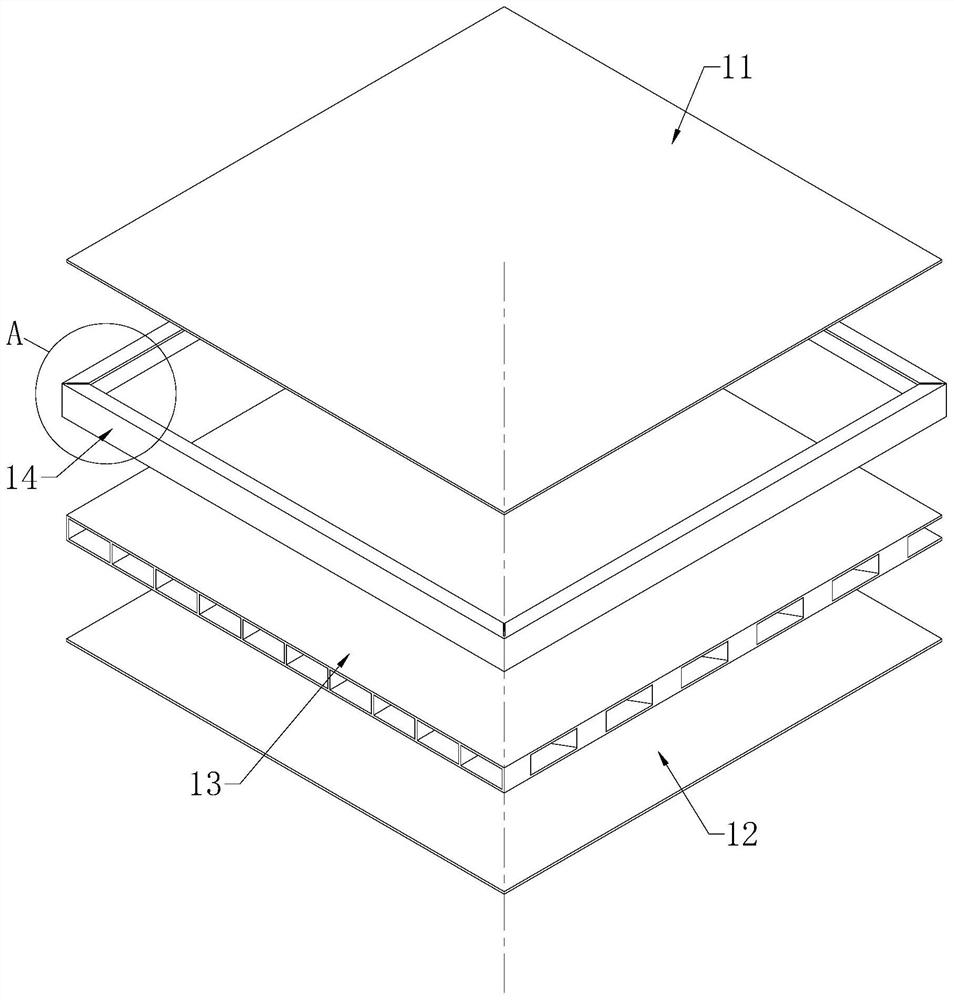

[0040] to combine figure 1 and image 3 As shown, the tray body 1 includes a honeycomb paperboard core 13 prepared by integral cutting of honeycomb boards, and the upper top surface and the lower bottom surface of the honeycomb paperboard core 13 are respectively bonded with a panel 11 and a bottom plate 12, that is, the tray body 1 is made of The panel 11, the honeycomb paperboard core 13 and the base plate 12 are sequentially bonded to form an integral structure. Adhesive board 14 is arranged on the peripheral side of the integral structure that panel 11 and honeycomb paperboard core 13 are bonded to form, and in the present...

Embodiment 2

[0048] refer to Figure 6 As shown, a paper pallet processing technology includes the following steps. First, the cardboard is cut according to the size data of the pre-designed digital model of the paper pallet (the cardboard can be made of environmentally friendly cardboard material or ordinary cardboard material) to prepare the pallet body 1 and The boards required for the foot column 2, that is, the panel 11 of the tray body 1, the honeycomb cardboard core 13, the bottom plate 12 and the reinforcement plate 14, as well as the peripheral side column 211, the end plate 212 and the foot cardboard 221 of the foot column 2 ; Then complete the splicing and combination production operation of the tray body 1 and the foot column 2, and finally complete the bonding and forming operation of the tray body 1 and the foot column 2.

[0049] In the process of processing the tray body 1, the bonding operation and pressing operation of the panel 11, the honeycomb cardboard core 13, the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com