Device and method for combined recovery of carbon dioxide, nitrogen and oxygen in flue gas

A carbon dioxide, nitrogen technology, applied in chemical instruments and methods, oxygen/ozone/oxide/hydroxide, carbon compounds, etc., can solve the problems of difficult separation and low enrichment of nitrogen and oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

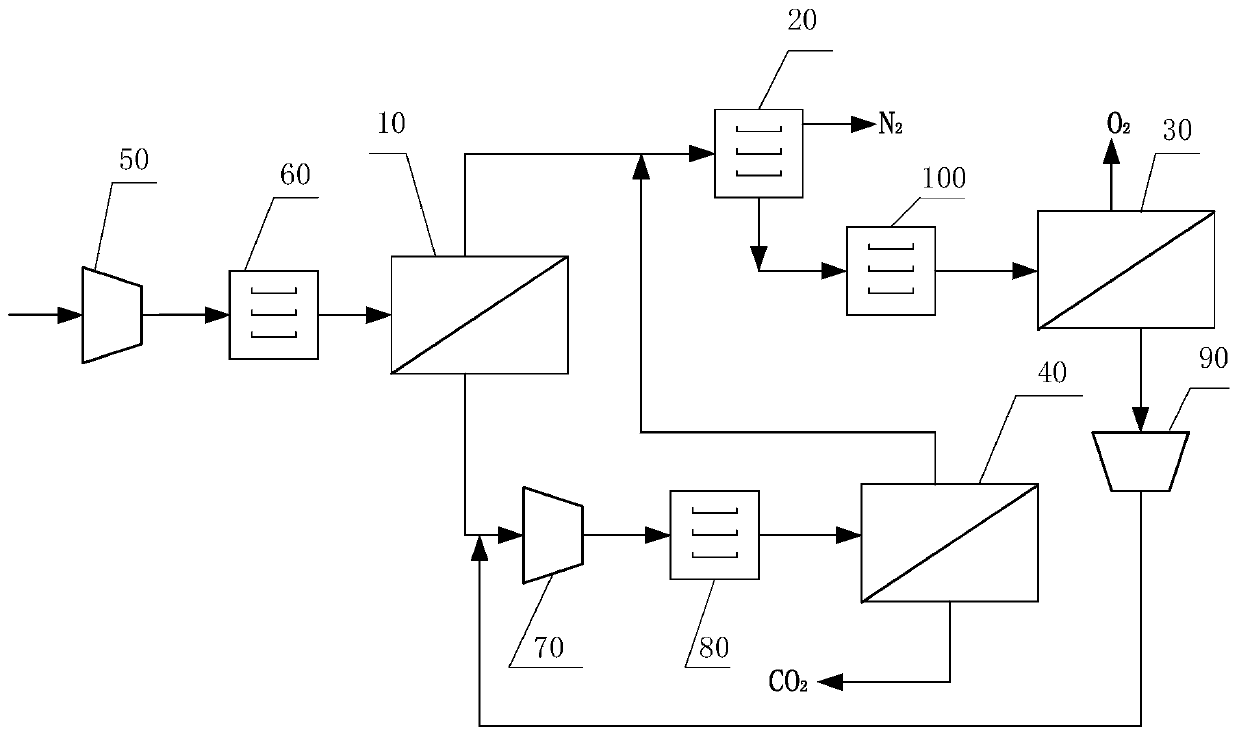

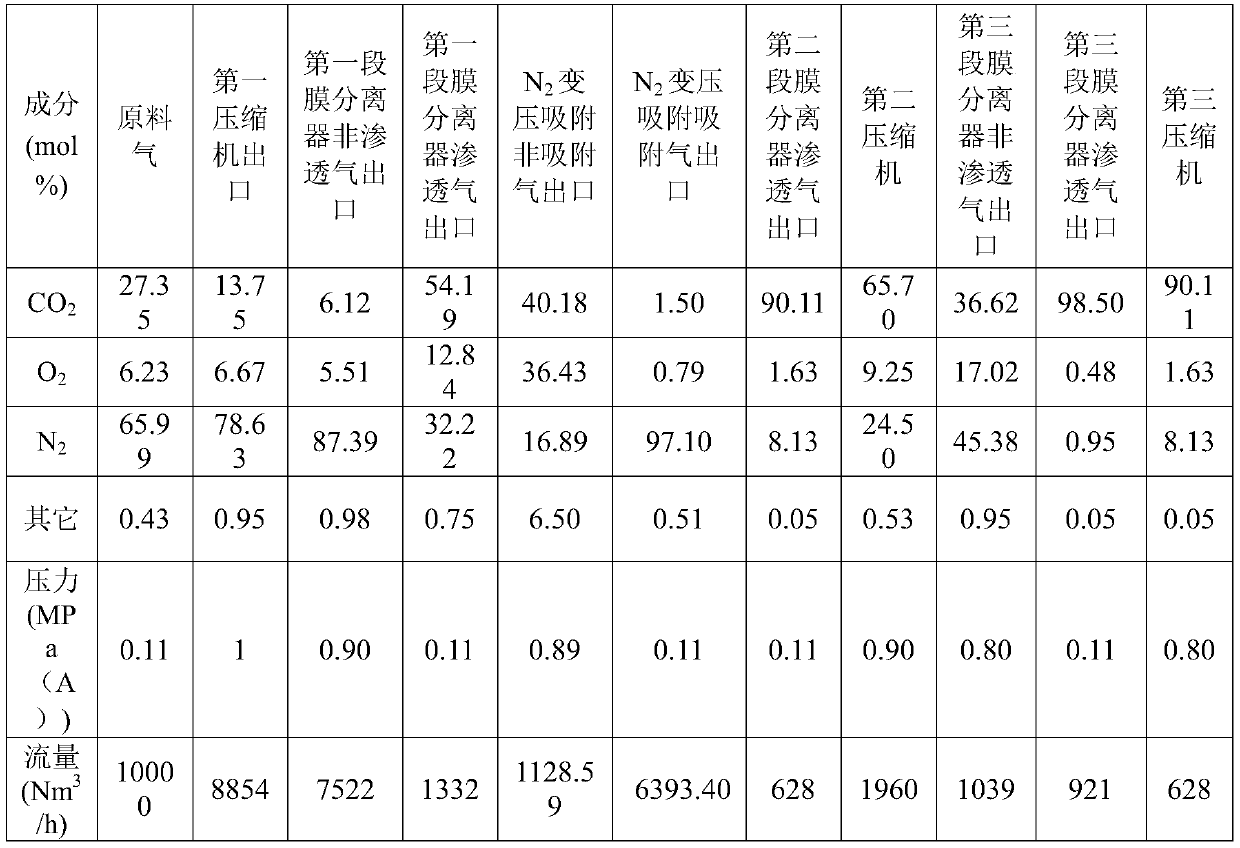

[0070] A steel plant flue gas is tested, and the balance calculation of the present invention figure 1 The device shown in is for low concentrations of CO in the flue gas 2 Process capture and treatment effects for oxygen and nitrogen recovery.

[0071] Among them, hollow fiber membranes made of organic membrane materials are used in the carbon dioxide membrane separation unit; in the step of nitrogen pressure swing adsorption separation, the process conditions are as follows: the treatment temperature is 30 degrees Celsius, the treatment pressure is 0.47MPa (A), and the adsorbent is carbon molecular sieve.

[0072] The material balance results are shown in Table 1:

[0073] Table 1

[0074]

[0075] From the above description, it can be seen that the above-mentioned embodiments of the present invention have achieved the following technical effects: as can be seen from Table 1, when the gas flow rate of the blast furnace flue gas processed is 10000Nm 3 / h, CO 2 Content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com