Preparation method of hydrophobic and oleophylic cellulose based aerogel

A cellulose and hydrophobic technology, applied in the direction of airgel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of non-reusable, low utilization rate, poor hydrophobicity, etc., achieve hydrophobic and oil-absorbing properties and can be recycled, method Simple and easy to operate, good hydrophobic and oil-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

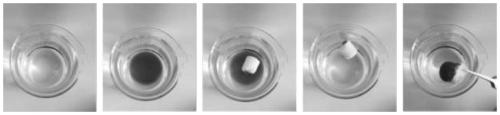

Image

Examples

Embodiment 1

[0030] (1) Dilute the commercially available cellulose nanofiber solution with water to a 1wt% concentration dispersion, and ultrasonically disperse at 45°C for 9 minutes until the cellulose nanofibers are uniformly dispersed in deionized water, according to the solid content of 10 / 0.5 (cellulose Nanofiber dry weight / crosslinking agent dry weight=10 / 0.5) Add crosslinking agent butane tetracarboxylic acid in proportion, maintain water temperature at 45°C, and continue ultrasonic dispersion for 65 minutes until the mixture is uniformly dispersed;

[0031] (2) Pour the uniformly dispersed mixture into a specific mold, place it in the refrigerator for pre-freezing at -18°C for about 12 hours, and freeze-dry it at -76°C for about 36 hours after the pre-freezing to obtain dry cross-linked cellulose nanofibers Aerogel;

[0032] (3) Configure a hexamethylene diisocyanate acetone solution with a concentration of 0.2wt% as a hydrophobic treatment agent, and soak the dried cellulose nano...

Embodiment 2

[0036] (1) Dilute the commercially available cellulose nanofiber solution with water to a 2wt% concentration dispersion, and ultrasonically disperse at 35°C for 10 minutes until the cellulose nanofibers are uniformly dispersed in deionized water, according to the solid content of 5 / 1 (cellulose Dry weight of nanofibers / dry weight of cross-linking agent = 5 / 1) Add the cross-linking agent epichlorohydrin in proportion, maintain the water temperature at 35°C, and continue ultrasonic dispersion for 120 minutes until the mixture is uniformly dispersed; the ultrasonic power is 100W, and the ultrasonic frequency 60KHz;

[0037] (2) Pour the uniformly dispersed mixture into a specific mold (a small glass bottle with a diameter of 1.3 cm), place it in the refrigerator for about 12 hours at -18°C, and freeze-dry it at -76°C for about 36 hours after the pre-freezing is completed. Obtain dry cellulose nanofiber cross-linked airgel;

[0038](3) configure the heptadecafluorodecyltriethoxys...

Embodiment 3

[0040] (1) Dilute the commercially available cellulose nanofiber solution with water to a 0.5wt% concentration dispersion, and ultrasonically disperse at 50°C for 5 minutes until the cellulose nanofibers are uniformly dispersed in deionized water, according to the solid content of 10 / 1 (fiber Dry weight of plain nanofibers / dry weight of cross-linking agent=10 / 1) Add the cross-linking agent butane tetracarboxylic acid in proportion, maintain the water temperature at 50°C, and continue ultrasonic dispersion for 30 minutes until the mixture is uniformly dispersed; the ultrasonic power is 500W, Ultrasonic frequency is 20KHz;

[0041] (2) Pour the uniformly dispersed mixture into a specific mold, place it in the refrigerator for pre-freezing at -18°C for about 12 hours, and freeze-dry it at -76°C for about 36 hours after the pre-freezing to obtain dry cross-linked cellulose nanofibers Aerogel;

[0042] (3) Diphenylmethane diisocyanate acetone solution with a concentration of 4wt% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com