Pulse detonation engine combustor and ignition method thereof

A technology of pulse detonation and engine, applied in the direction of machine/engine, rocket engine device, mechanical equipment, etc., can solve problems such as not being well solved, and achieve the effect of reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

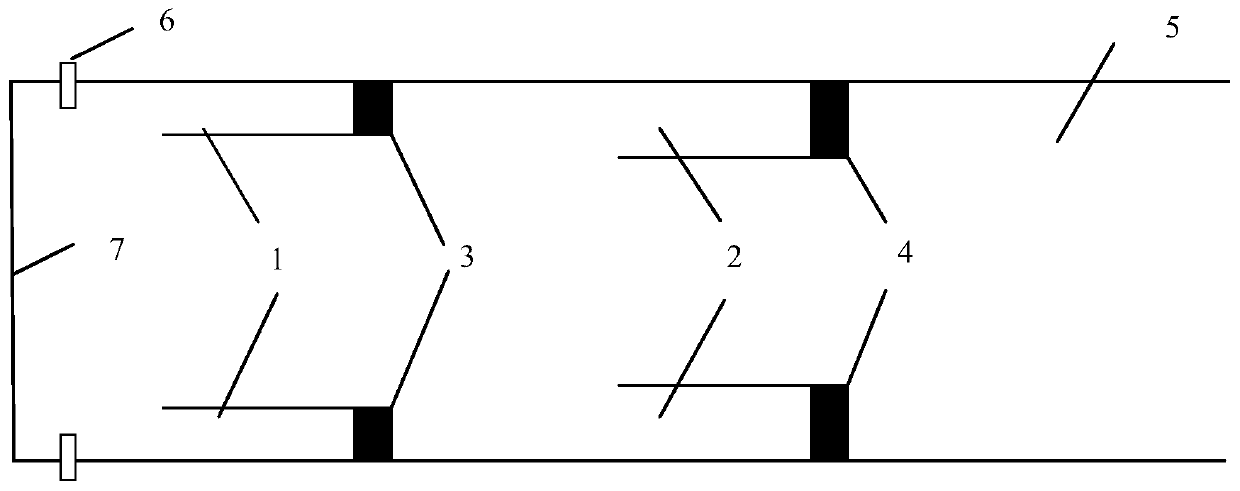

[0026] Such as figure 1 As shown, a pulse detonation engine combustion chamber in the present invention includes a main detonation chamber, a fuel nozzle and an air intake valve; the fuel nozzle is arranged on the wall or end surface of the main detonation chamber, and can spray into the main detonation chamber For fuel, the suction valve is arranged on the wall or end surface of the main detonation chamber, which can suck oxidizer or air into the main detonation chamber; the suction valve is a rotary valve, when the valve is opened, the oxidant or air required for combustion is introduced, when the valve When closed, the valve acts as a wall; the right end of the main detonation chamber is the outlet, which communicates with the outside world.

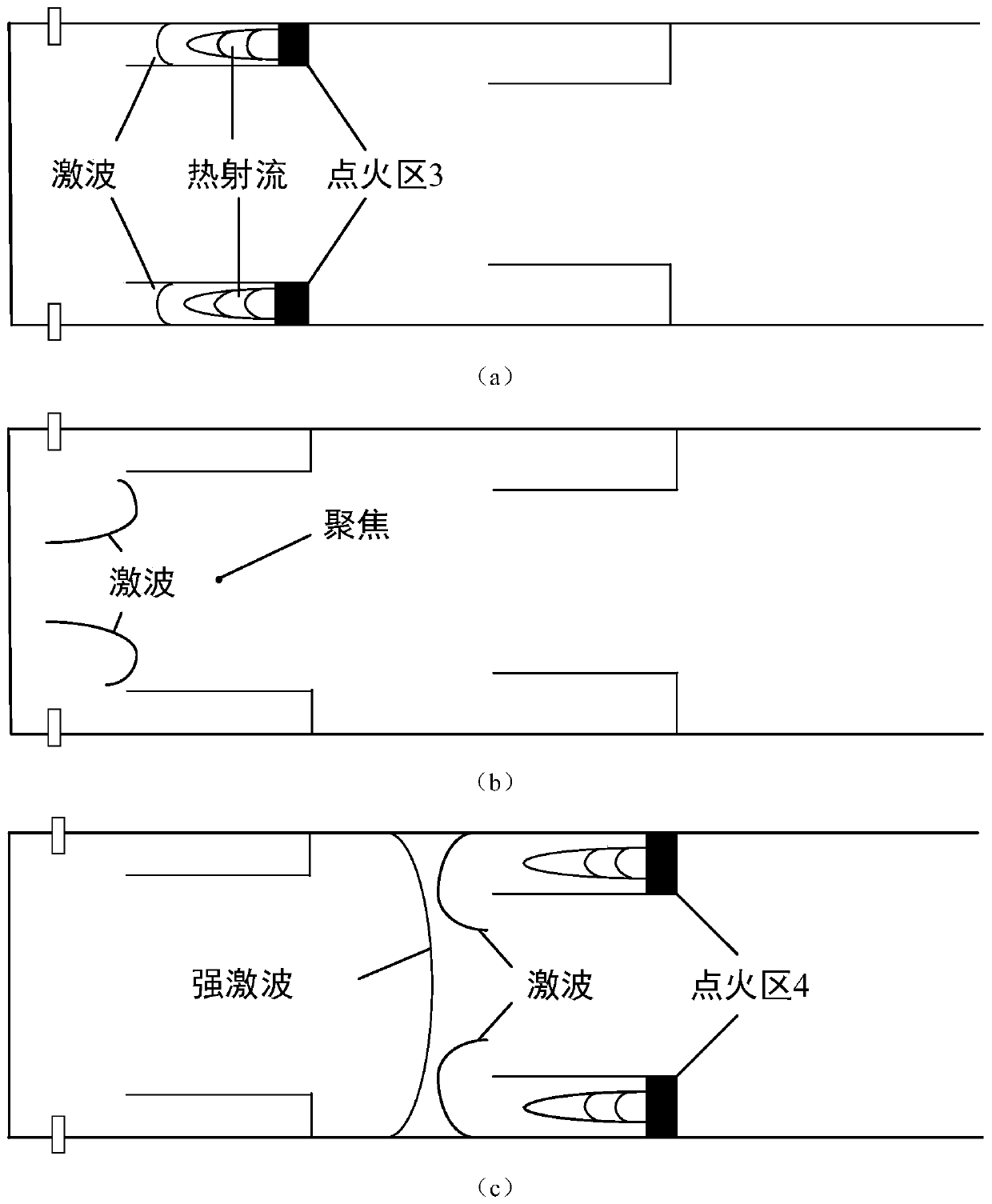

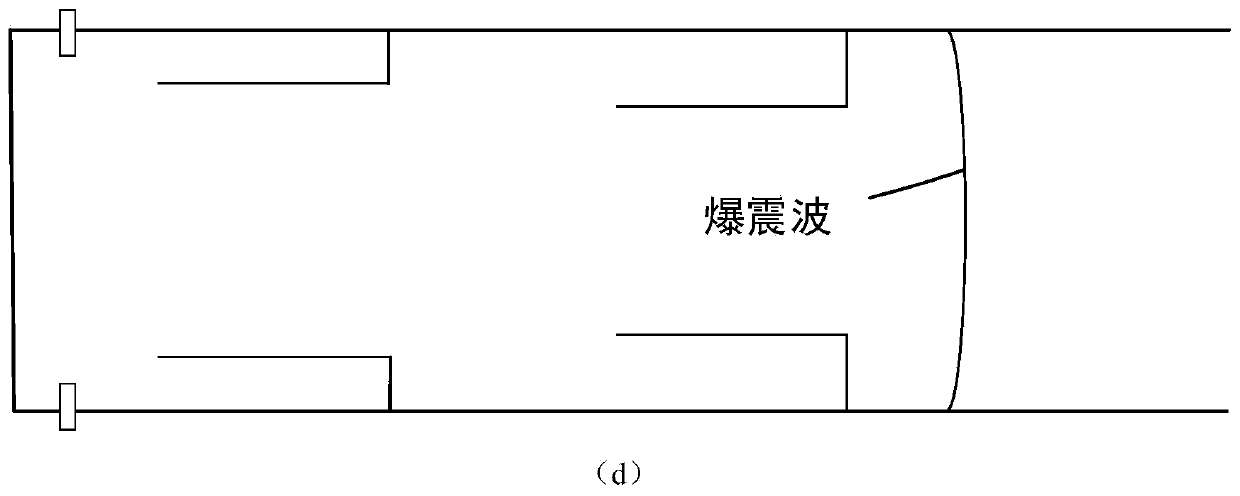

[0027] There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com