Polyurea anti-corrosion and anti-explosion magnetic flux sensor and manufacturing method thereof

The invention relates to a magnetic flux sensor and a manufacturing method, which are used in monitoring devices, polyurea anti-corrosion and anti-explosion magnetic flux sensors and their manufacture, and in the field of bridge cable force detection. and other problems, to achieve the effect of improving the overall anti-corrosion performance and anti-knock performance, good anti-knock performance and enhancing adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A polyurea anti-corrosion and anti-explosion magnetic flux sensor:

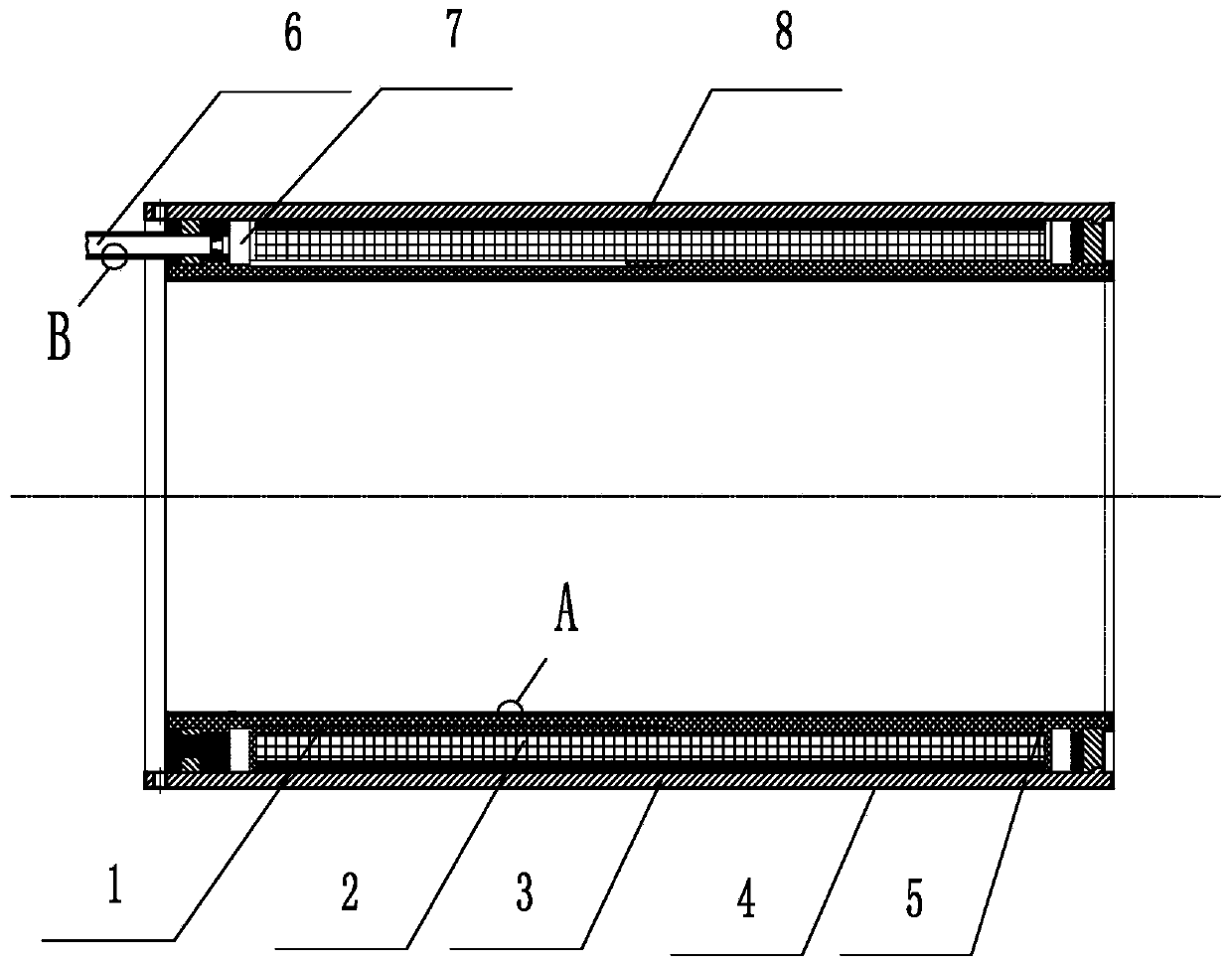

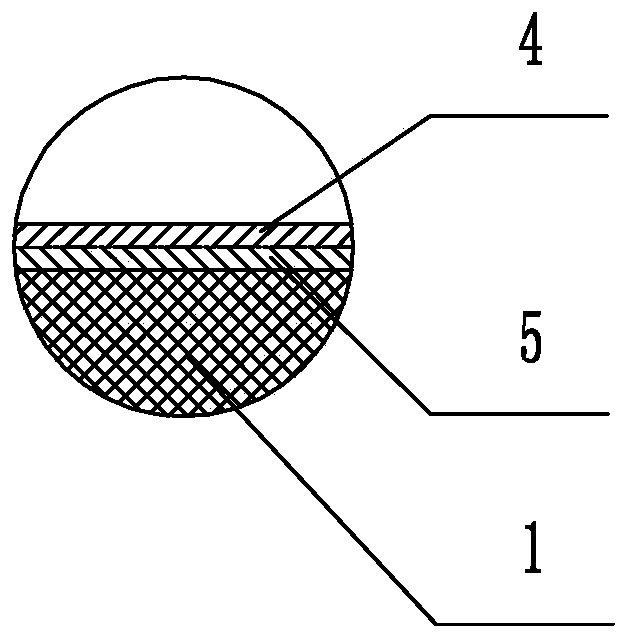

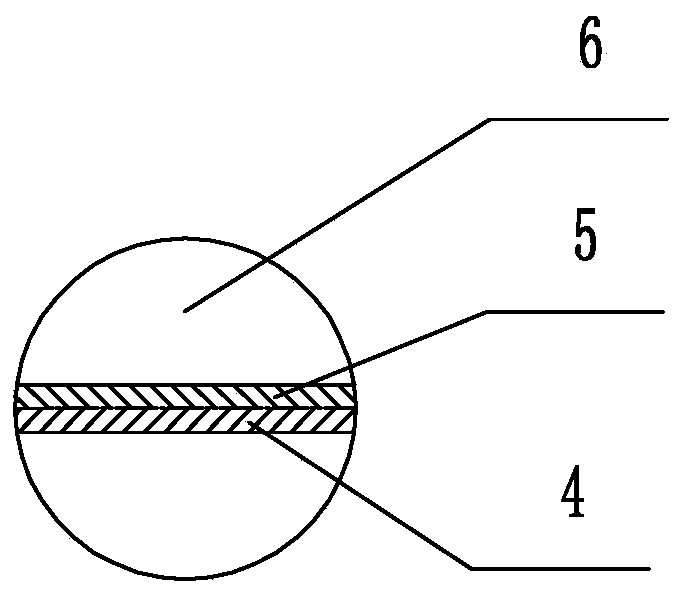

[0049] Such as Figure 1-Figure 3 As shown, the polyurea anti-explosion anti-corrosion magnetic flux sensor includes a bobbin 1, a coil 2, an outer sleeve 3 and a data line 6, the coil 2 is wound outside the bobbin 1, and the data line 6 passes through the outlet baffle 7 and the coil 2 connection, the gap between the coil 2 and the outer sleeve 3 is filled with epoxy resin 8, the outer surfaces of the bobbin 1 and the outer sleeve 3 are respectively coated with a layer of adhesive layer 5, and the outer surface of the adhesive layer is coated with a A layer of polyurea layer 4, the outer surface of the outlet of the data line 6 is also coated with a layer of adhesive layer 5, and the outer surface of the adhesive layer is coated with a layer of polyurea layer 4.

[0050] The material constituting the polyurea layer 4 is polyurea material, including pure polyurea material or semi-polyurea material; it...

Embodiment 2

[0054] A method for manufacturing a polyurea anti-corrosion and anti-explosion magnetic flux sensor.

[0055] It is a method for making a polyurea anti-corrosion and anti-explosion magnetic flux sensor described in Example 1, and its preparation process includes the following steps:

[0056] A. Basic treatment

[0057] A1. Treatment of the outer sleeve 3:

[0058] A11. Grind off the welding nodules, welding slag, and spatter on the weld seam of the outer sleeve 3 of the magnetic flux sensor, and remove grease, oil stains and other sundries on the metal surface;

[0059] A12, sandblasting the outer sleeve 3 obtained in the above-mentioned A11 step to Ra2.5 or above, cleaning the substrate after the sandblasting, completely removing grease, rust spots and other sundries on the metal surface, and removing dust;

[0060] A2. Processing of spool 1 and data line 6:

[0061] Wipe the surface of bobbin 1 and data line 6 with alcohol or acetone to remove moisture, grease, dust and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com