Automatic positioning concrete powder picking machine based on phased array ultrasonic scanning

An automatic positioning and ultrasonic technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, sampling devices, measuring devices, etc., can solve the problems of powder flying in the air, error of analysis results, operator injury, etc., to improve powder collection efficiency, The effect of high accuracy and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

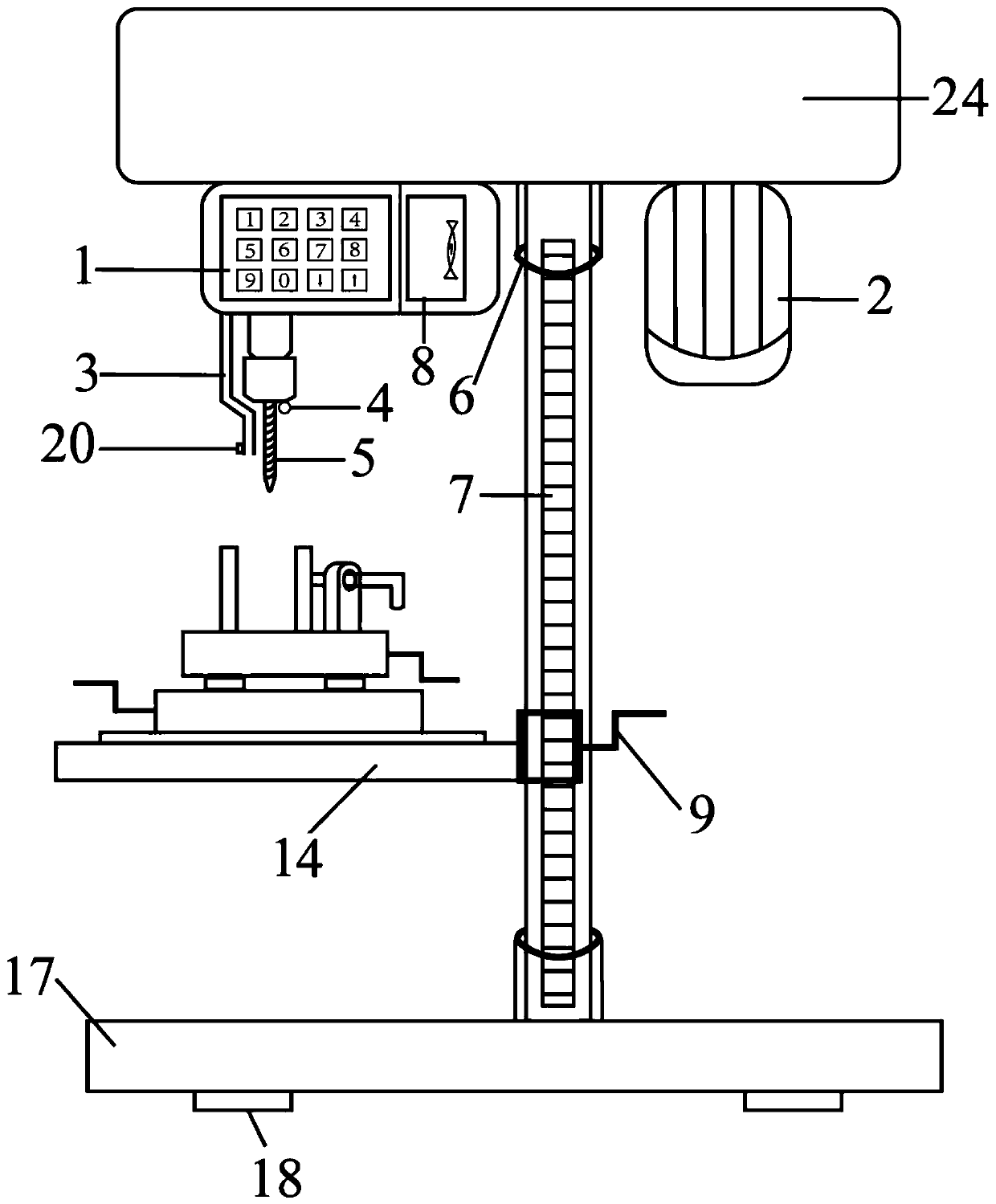

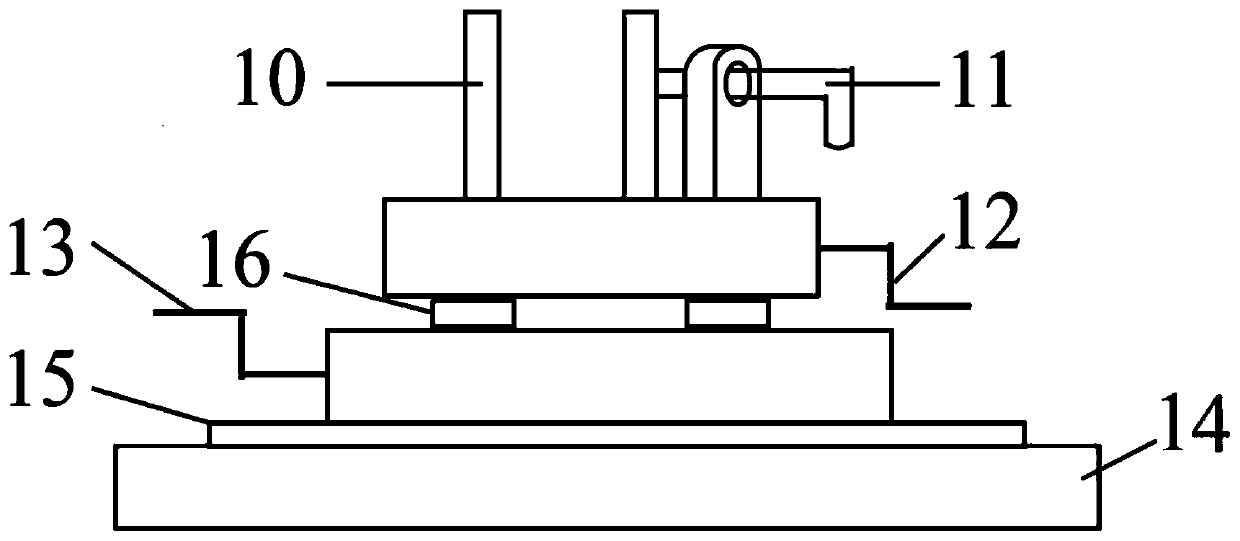

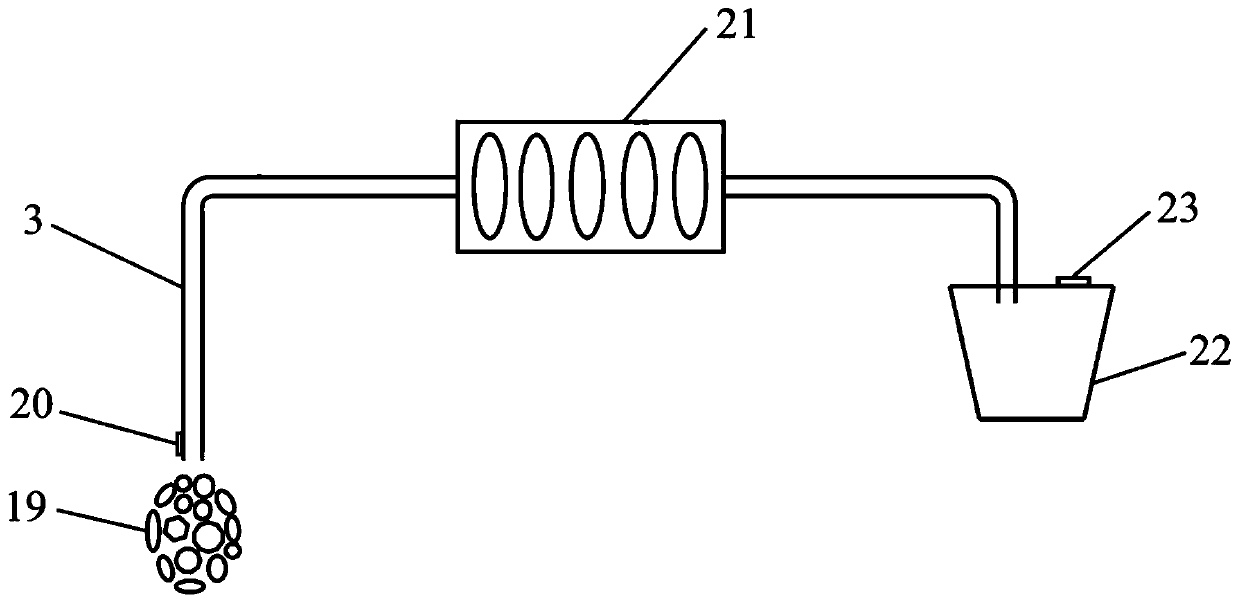

[0033] like Figure 1 ~ Figure 3 As shown, an automatic positioning concrete powder extractor based on phased array ultrasonic scanning includes a support base 17, and a vertical lifting rod 7 is provided on the supporting base 17; Table 14, said test piece fixing table 14 is provided with a vertical and horizontal moving mechanism, and an adjustable clamp block 10 is arranged above said vertical and horizontal moving mechanism; said vertical elevating rod 7 top is also provided with a mounting table 24, said mounting table 24 The bottom is provided with a powder extraction drill operation controller, and the bottom of the powder extraction drill operation controller is provided with an electrically connected drill walking module. An ultrasonic scanner 4 ; an automatic powder collector 8 is also provided near the powder extraction drill 5 , and the automatic powder collector 8 is connected to the installation platform 24 . The powder extraction bit operation controller includ...

Embodiment 2

[0048] A method of drilling powder for an automatic positioning concrete powder extractor based on phased array ultrasonic scanning, comprising the following steps:

[0049] Step 1: The ultrasonic sensor scans the size of the test piece to obtain the side length (length and width) and height of the test block, and sends the side length information of the test block to the powder extraction drill operation controller. The calculation module takes the center of the test block as the coordinate origin, the length direction of the test block as the X axis, the width direction of the test block as the Y axis, and the height direction of the test block as the Z axis to establish a Cartesian coordinate system;

[0050] Step 2: Input the coordinates of the desired powder extraction position from the center of the test piece and the number of required powder extraction points in the powder extraction drill operation controller, and the calculation module in the powder extraction drill o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com