Ligament bracket, shaping method of ligament bracket, and ligament implanting materials formed from ligament bracket

A ligament and biological technology, applied in the field of medical tissue engineering scaffold manufacturing, can solve the problems of difficult and rapid large-scale preparation, low mechanical strength of ligament scaffolds, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

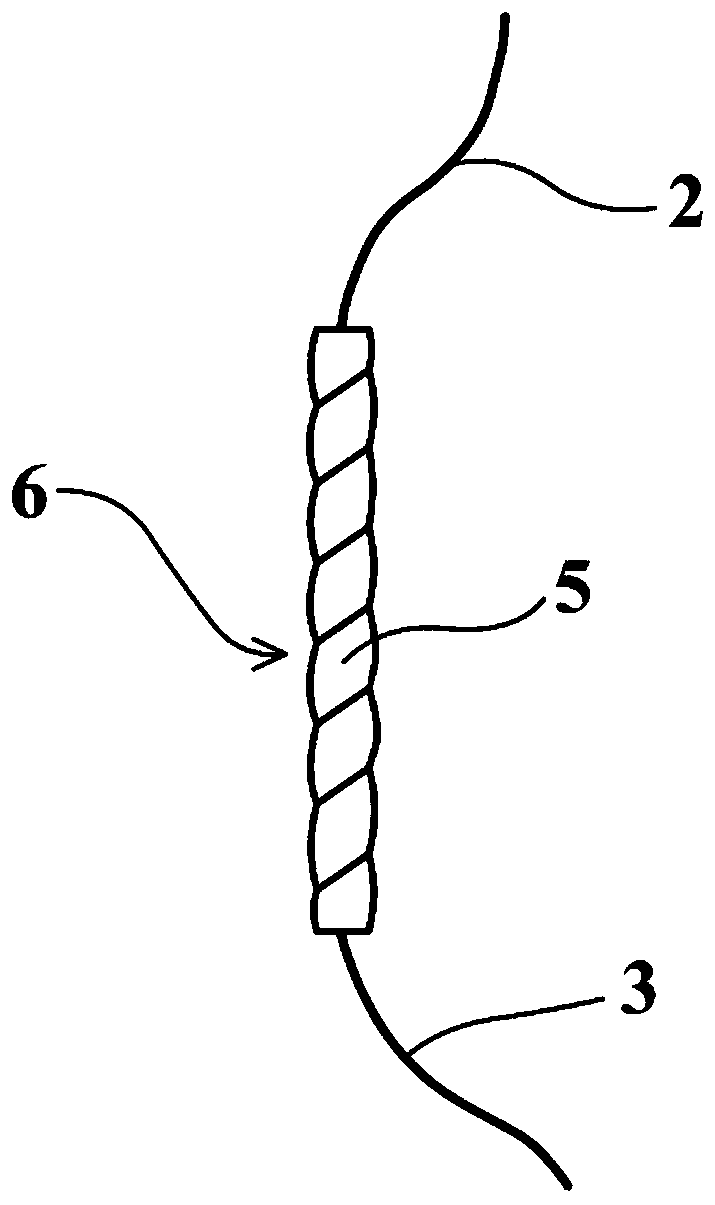

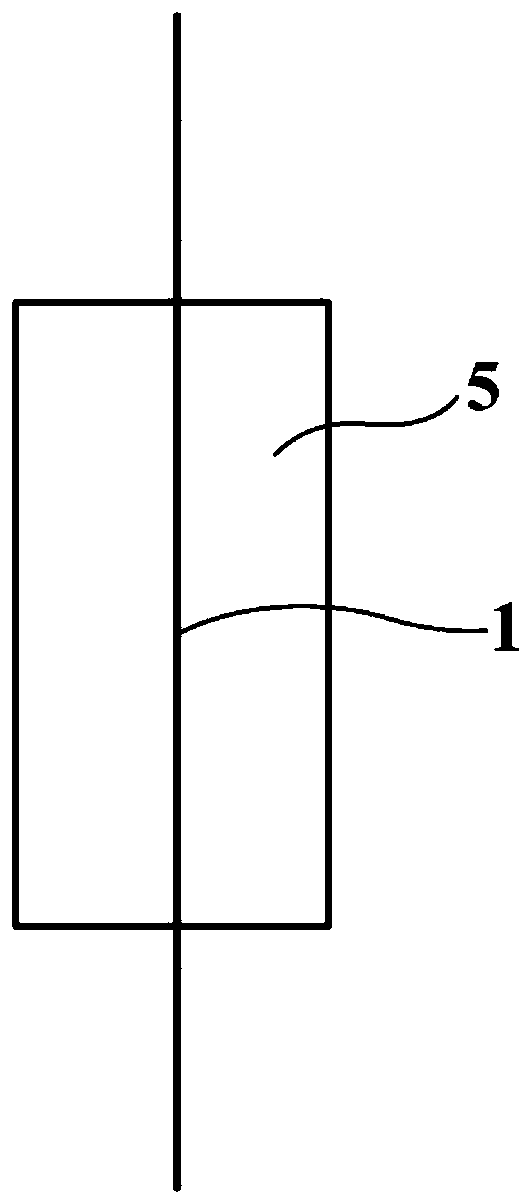

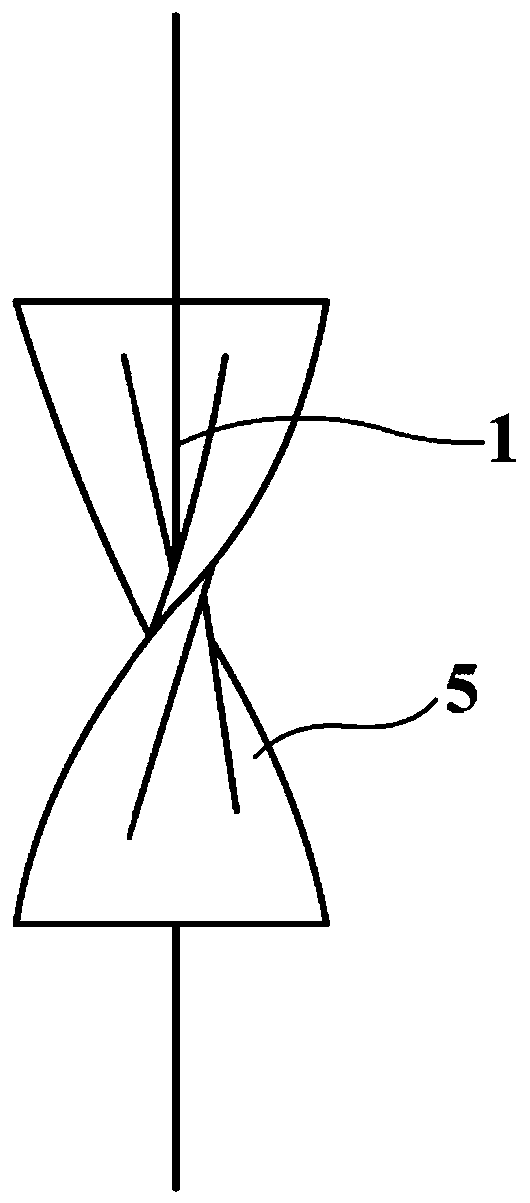

[0025] Figure 1 to Figure 7 A first embodiment of the invention is shown. in, figure 1 A ligament support 6 of the present embodiment is shown, which is used for a cruciate ligament support. The ligament support 6 is a core-sheath composite structure, wherein the core is a USP2-0PDSII biodegradable suture 1 with a length of 150 mm and a diameter of 0.35 mm. The sheath of the ligament support 6 is composed of a nanofiber membrane 5 prepared by electrospinning a mixed solution of silk fibroin and polycaprolactone, which is tightly wrapped and fixed on the outside of the suture 1 through twisting and twisting. The direction is Z twist, and the twist is about 90 twists / m. The initial shape of the electrospun nanofiber membrane 5 is a rectangle, the initial length is 80 mm, the initial width is 40 mm, and the initial thickness is 0.3 mm. The main body of the ligament support 6 is approximately cylindrical and has a diameter of 6 mm. Due to the twisting, the final main body len...

Embodiment 2

[0032] Figure 8 to Figure 14 A second embodiment of the invention is shown. in, Figure 8A ligament support 6 of the present embodiment is shown, which is used for a cruciate ligament support. The ligament support 6 is a core-sheath composite structure, in which the core is 2 USP7-OPDSII biodegradable sutures 1 with a length of 170 mm and a diameter of 0.07 mm bundled together. The sheath of the ligament support 6 is a nanofiber membrane 5 prepared by electrospinning a mixed solution of silk fibroin and caprolactone lactate copolymer P (LLA-CL), which is tightly wrapped and fixed by twisting and twisting. It is formed outside the suture 1, the twist direction is S twist, and the twist is about 80 twists / m. The wrapped electrospun nanofiber membrane 5 has an initial shape of a rectangle, an initial length of 100 mm, an initial width of 50 mm, and an initial thickness of 0.4 mm. The main body of the ligament support 6 is approximately cylindrical and has a diameter of 7 mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com