Volume fracture dynamic flow-back simulation device and method

A simulation device and volumetric fracturing technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of prolonging the residence time of fracturing residual fluid, unfavorable reservoir protection, and reducing fluid drainage speed, etc. Achieve the effect of accurate and reliable experimental data, avoid skew, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

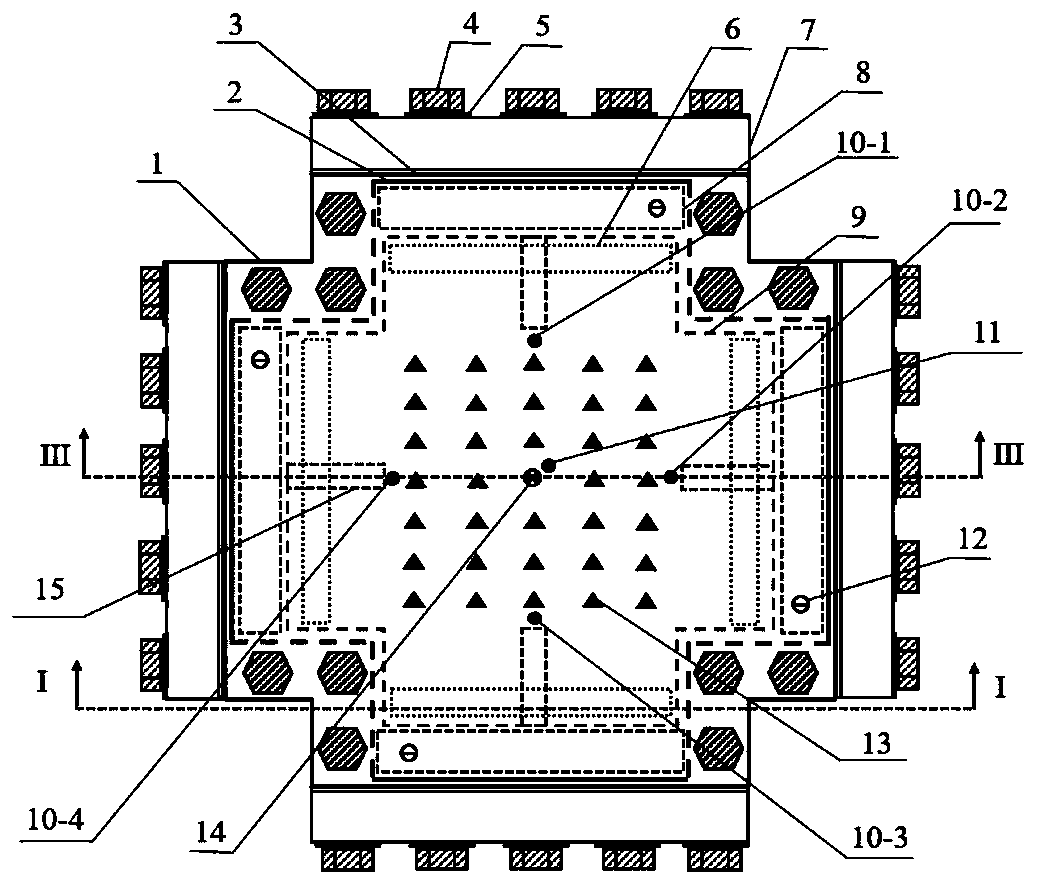

[0054] Example 1. Volume fracturing dynamic flowback simulation device

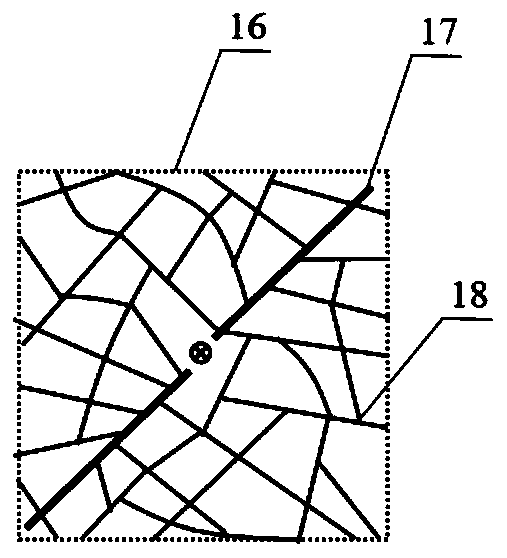

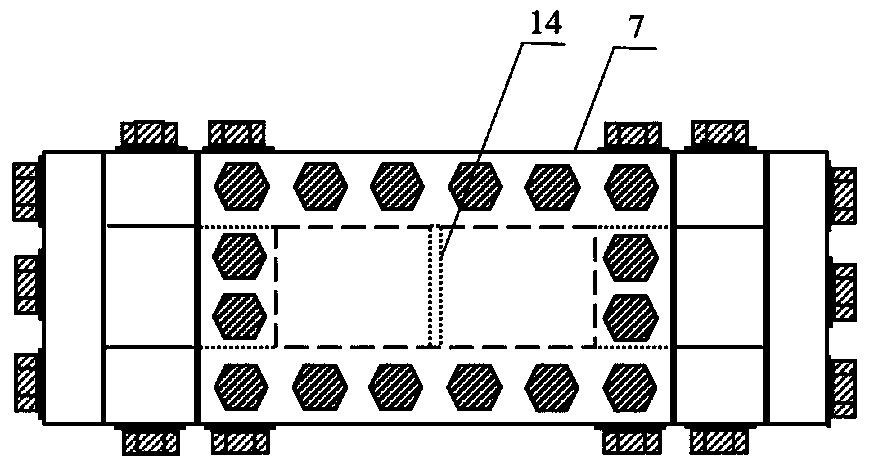

[0055] The volume fracturing dynamic flowback simulation device of the present invention, its overall structure schematic diagram (top view) is as follows figure 1 As shown, the dimensions of the dynamic flowback simulation device for volume fracturing are: length: 120-150 cm, width: 120-150 cm, height: 45-60 cm. The simulation device includes an airtight casing 19 and an experimental chamber, wherein the experimental chamber is divided into a high-temperature and high-pressure working chamber 9 and a dynamic control Cavity 8. The movable sealed steel plate 6 passes through the slide rail 15 and the airtight casing 19 (with a thickness of 16-20cm and a pressure resistance of 0-90MPa) and the upper (lower) steel plate 1 (with a thickness of 16-20cm and a pressure resistance of 0-90MPa ) sealing connection, the slide rail 15 can ensure that the movable sealing steel plate 6 moves along a determined track,...

Embodiment 2

[0061] Example 2. The method of using the dynamic flowback simulation device for volume fracturing

[0062] Use the volume fracturing dynamic flowback simulation device of the present invention according to the following steps:

[0063] (1) Assemble all the parts included in the above simulation device;

[0064] (2) Pressure test:

[0065] Connect the sand-carrying fluid injection pipe 14 of the dynamic flowback simulation device for volume fracturing to the high-pressure pipeline for fracturing with a valve, open the valve, and feed the fracturing fluid base fluid into the dynamic flowback simulation device for volume fracturing to perform Pressure suppression treatment, maintain the highest working pressure for 30-40 minutes, and the qualified standard of the pressure test is no puncture or leakage. Determine the maximum working pressure according to the specific construction site.

[0066] (3) Control system pressure:

[0067] The liquid is injected into the dynamic con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com