A coal seam fissure grouting plugging device

A plugging device and fissure technology, applied in shaft equipment, shaft lining, mining equipment, etc., can solve problems such as coal seam instability, support instability, crack expansion, etc., to prevent mine accidents, ensure integrity, and prevent collapse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

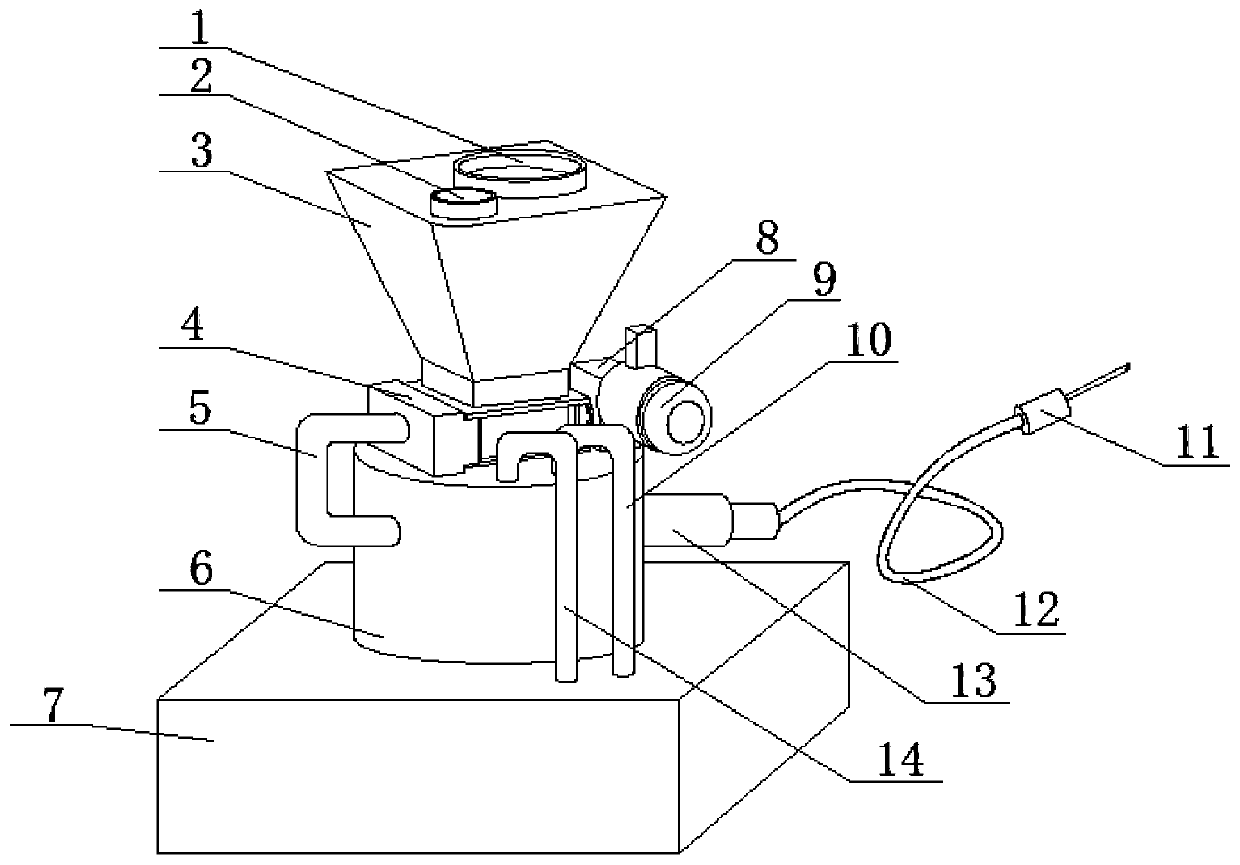

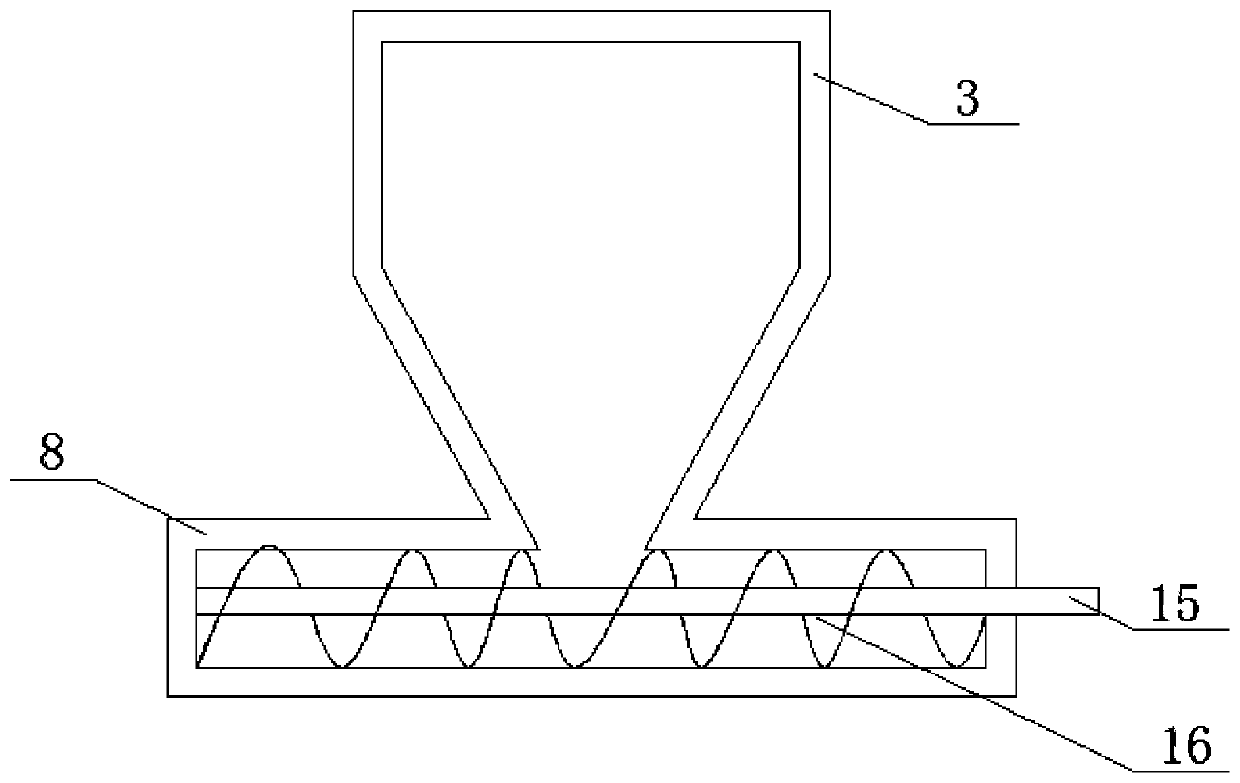

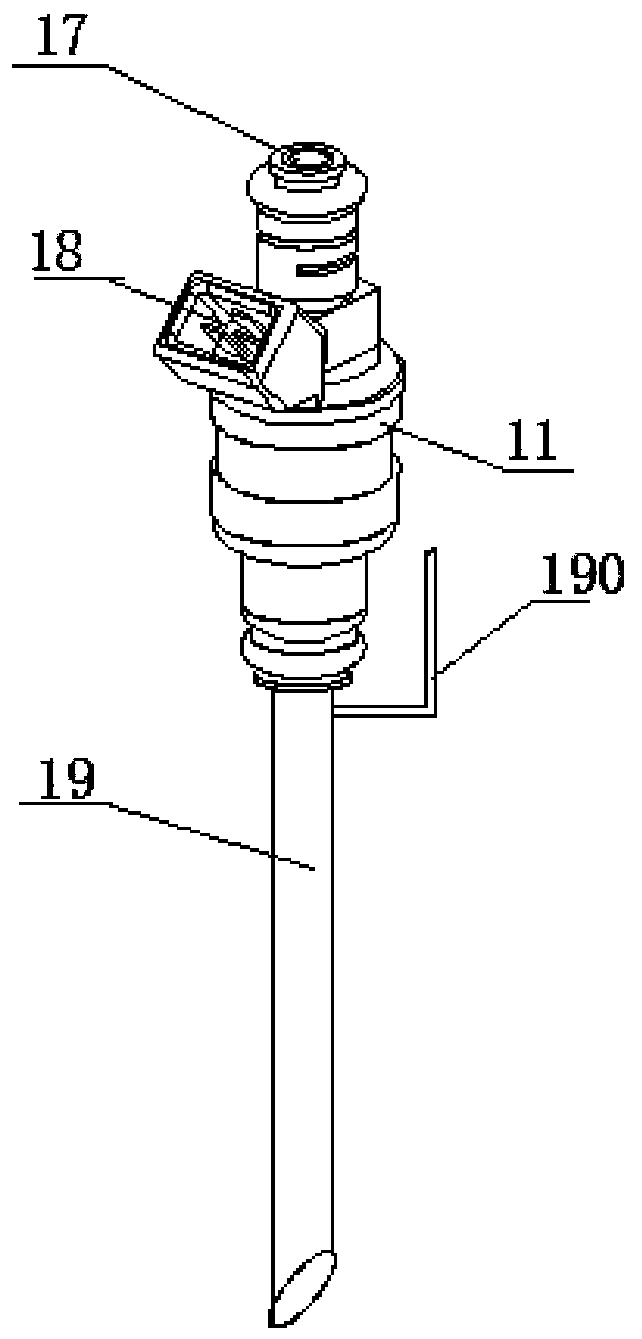

[0028] refer to Figure 1-6 , a coal seam fissure grouting plugging device, comprising a base 7, a mixed grouting device, a fissure internal plugging mechanism and a fissure external plugging mechanism, wherein the base 7 is fixedly provided with the grouting grouting device , it is characterized in that, the output end of the mixed grouting equipment is connected with a joint 13, and the replaceable connection on the joint 13 is provided with one of the crack internal sealing mechanism and the crack external sealing mechanism;

[0029] The end of the internal fissure sealing mechanism can extend into the coal seam fissures, so as to seal the internal fissures of the coal seam; the external fissure sealing mechanism can perform high-pressure spraying on the outer surface of the coal seam and seal the outer surface fissures of the coal seam. A layer of plugging slurry is applied to form a protective layer on the outer surface of the coal seam.

[0030] In this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com