Preparation method of supercapacitor based on working electrode made of hierarchical porous carbon material

A technology for supercapacitors and working electrodes, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of inability to achieve large-scale mass production, high synthesis cost by template method, and reduced commercial value, so as to improve capacitance Performance and storage capacity, convenient for transportation and storage, wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Place the biomass tata pine in an oven at 110° C. for seven days until the biomass is completely dry, and then grind it into powder in a pulverizer to obtain material A1.

[0033] (2) Transfer the material A1 to a nickel boat and place it in a tube furnace, raise the temperature from room temperature to 300°C for 60 minutes under the condition of nitrogen as a protective gas, then keep it at 300°C for 60 minutes, and then heat up for 60 minutes to 600°C and carbonized at 600°C for 2 hours, and then naturally cooled to room temperature to obtain material B1;

[0034] (3) Mix 0.5g of material B1 and KOH solid in a 500mL beaker at a mass ratio of 1:4, then add 5-7mL of deionized water and stir well to make it evenly mixed. After standing for 8 hours at room temperature, place it at 105℃ drying in an oven to obtain material C1;

[0035](4) Transfer the material C1 to a nickel boat and place it in a tube furnace, raise the temperature from room temperature to 300°C for ...

Embodiment 2

[0038] (1) Place the biomass tata pine in an oven at 110°C for seven days until the biomass is completely dry, and then grind it into powder in a pulverizer to obtain material A2;

[0039] (2) Transfer the material A to a porcelain boat and place it in a tube furnace, raise the temperature from room temperature to 300°C for 60 minutes with nitrogen as the protective gas, then keep it at 300°C for 60 minutes, and then heat up for 60 minutes to 600°C and carbonized at 600°C for 2 hours, and then naturally cooled to room temperature to obtain material B2;

[0040] (3) Mix 0.5g of material B2 and KOH solid in a 500mL beaker at a ratio of 1:3 by mass, then add 5-7mL of deionized water and stir well to make it evenly mixed, let it stand at room temperature for 8 hours and then dry it to obtain Material C2;

[0041] (4) Transfer the material C to a nickel boat and place it in a tube furnace, raise the temperature from room temperature to 300°C for 60 minutes under the condition of n...

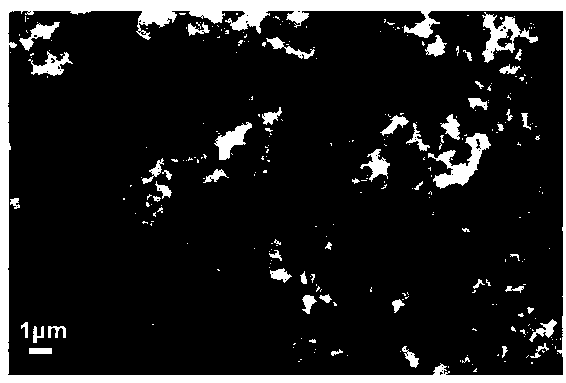

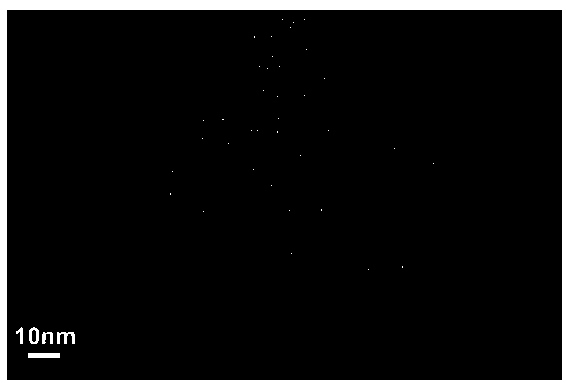

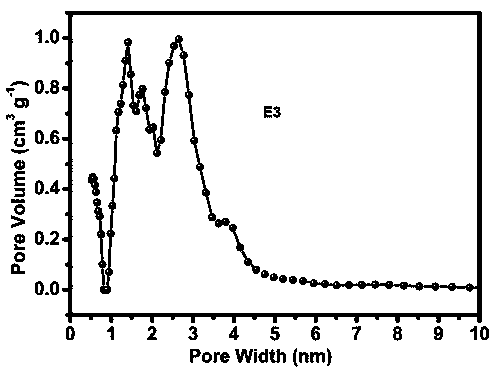

Embodiment 3

[0044] (1) Place the biomass tata pine in an oven at 110°C for seven days until the biomass is completely dry, and then grind it into a powder in a pulverizer to obtain material A3;

[0045] (2) Transfer the material A3 to a porcelain boat and place it in a tube furnace, raise the temperature from room temperature to 300°C for 60 minutes with nitrogen as the protective gas, then keep it at 300°C for 60 minutes, and then heat up for 60 minutes to 600°C and carbonized at 600°C for 2 hours, and then naturally cooled to room temperature to obtain material B3;

[0046] (3) Mix 0.5g of material B3 and KOH solid in a 500mL beaker at a ratio of 1:4 by mass, then add 5-7mL of deionized water and stir well to make it evenly mixed. drying in an oven to obtain material C3;

[0047] (4) Transfer the material C3 to a nickel boat and place it in a tube furnace, raise the temperature from room temperature to 300°C for 60 minutes under the condition of nitrogen as a protective gas, then keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com