Method for measuring first coulombic efficiency of lithium batteries and material system preference method

A technology of Coulombic efficiency, lithium-ion battery, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as inability to prevent, incapable of gas removal, reduction of cell capacity, etc., to achieve elimination of influence, good effectiveness, good electricity Effects of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

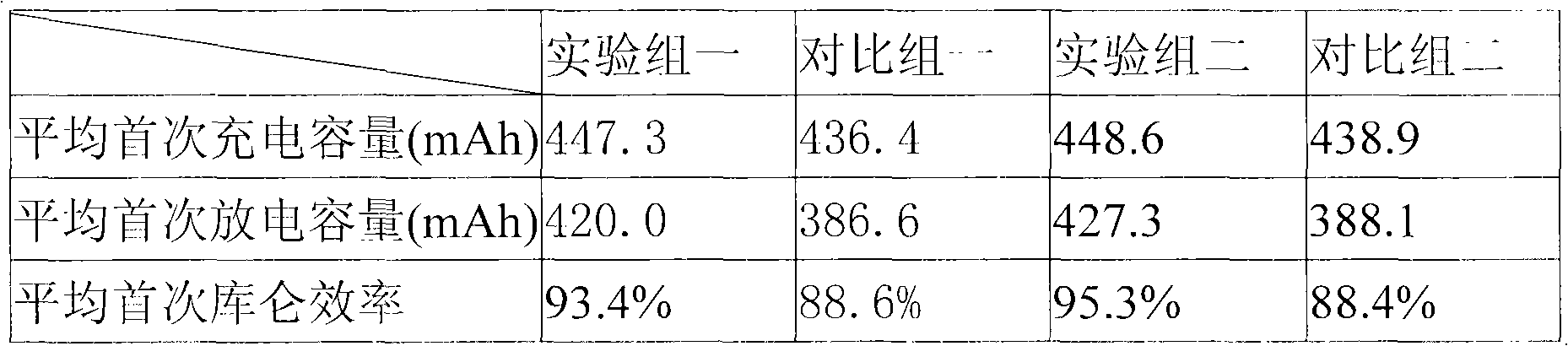

[0020] Using nickel-cobalt lithium manganese oxide as the positive electrode material and natural graphite as the negative electrode material, assemble 200 batteries of model 423040AH (thickness × width × height = 4.5mm × 30mm × 40mm, rated voltage = 3.7V), inject liquid and age Afterwards, they were divided into a test group 1 and a control group 1, 100 in each group.

[0021] The coulombic efficiency of the 100 batteries of the experimental group 1 is measured, and the steps are as follows:

[0022] a) Connect the liquid-injected and aged Li-ion battery to the coulometric device.

[0023] b) Use a pressure-resistant, corrosion-resistant rubber hose or metal tube to connect the liquid injection hole of the battery to the vacuum device, and seal the connection to prevent air from entering, start the vacuum device to vacuum the inside of the battery, and maintain the pressure during vacuuming is 0.03MPa.

[0024] c) Charge the battery with a constant current of 40mA to 4.2V, ...

Embodiment 2

[0031] In order to ensure the comparative nature of the experiment, the battery manufactured in this example is the same as that of Example 1 except that the negative electrode material is replaced with a modified natural graphite negative electrode material. That is, nickel-cobalt lithium manganate is used as the positive electrode material, and modified natural graphite is used as the negative electrode material, and 200 batteries with a model number of 423040AH (thickness × width × height = 4.5mm × 30mm × 40mm, rated voltage = 3.7V) are assembled, and the liquid is injected 1. After aging, they were divided into test group 2 and contrast group 2, 100 in each group.

[0032] The coulombic efficiency was measured for 100 batteries of experimental group 2, and the steps were as follows:

[0033] a) Connect the liquid-injected and aged Li-ion battery to the coulometric device.

[0034] b) Use a pressure-resistant, corrosion-resistant rubber hose or metal tube to connect the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com