Preparation method for proton exchange membrane fuel cell gas diffusion layer under high current density

A proton exchange membrane, high current density technology, used in fuel cells, electrical components, battery electrodes, etc., can solve problems such as poor thickness and uniformity, complicated preparation process of microporous layer, and unsatisfactory water management capability of gas fuel cells. , to achieve the effect of uniform thickness, improved single cell performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

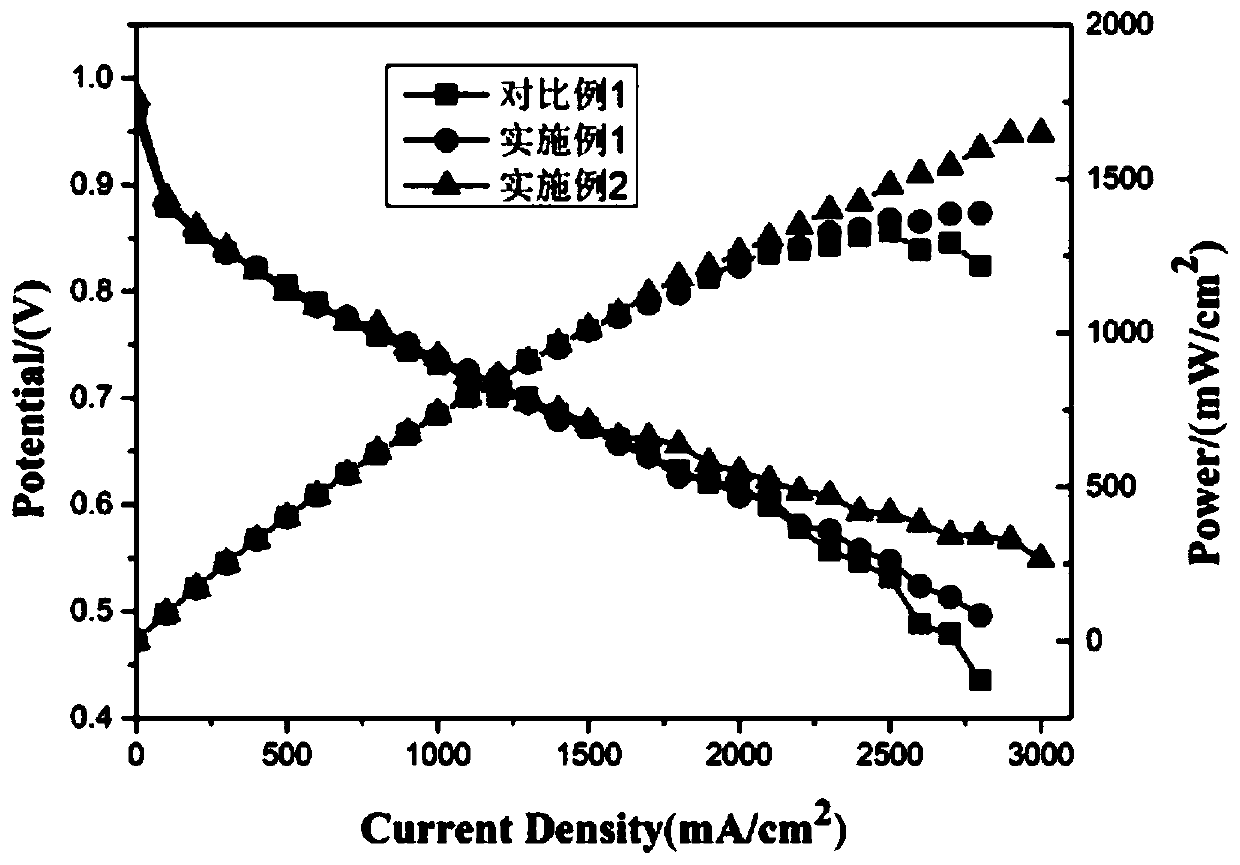

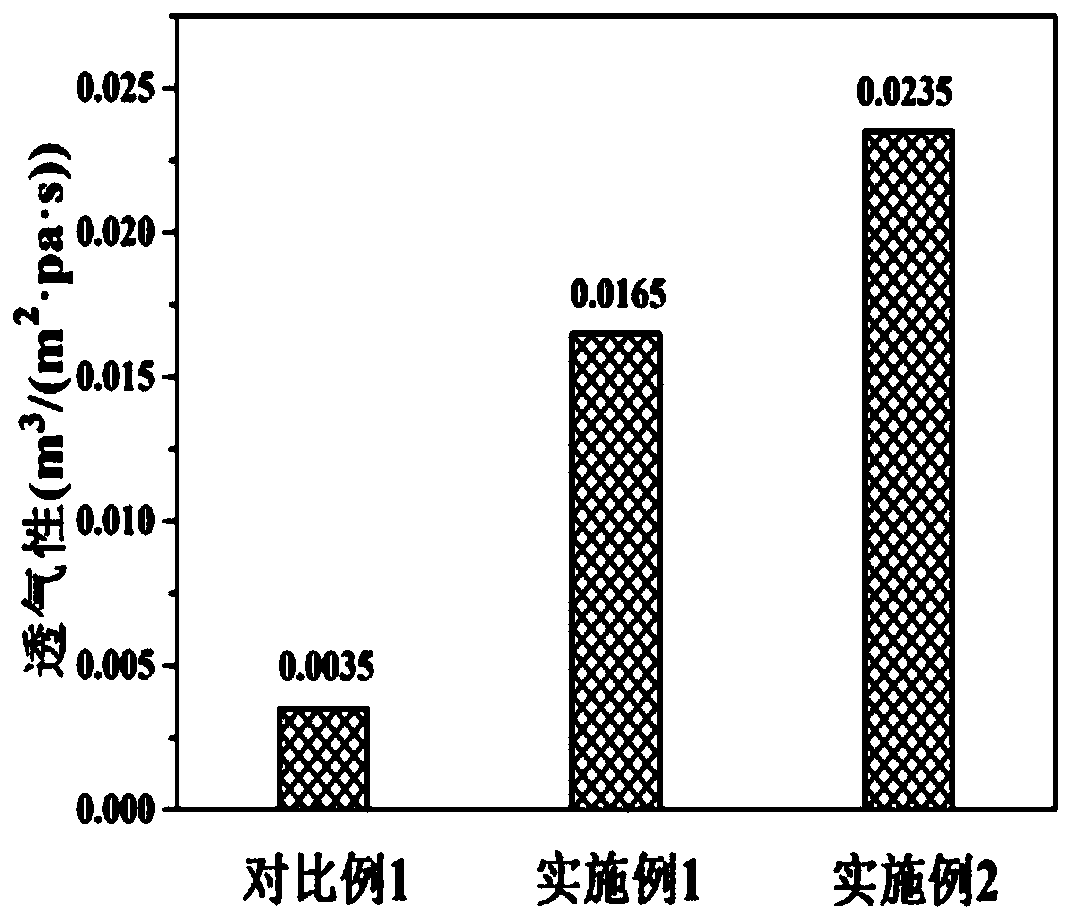

[0025] Mix 1.5g of carbon powder (Vulcan XC-72) and 15g of deionized water and stir evenly, then add 0.6g of 60% polytetrafluoroethylene (PTFE) emulsion and 0.225g of ammonium carbonate in sequence to obtain a slurry . The slurry is coated on the side of the base layer that has been hydrophobicized and dried in advance by a knife coating method to obtain a gas diffusion layer (loading 2.0mg / cm 2 ). Place the gas diffusion layer in an oven at 150°C for drying, and then transfer to a N-pass 2 Sintered in a tube furnace at 350°C for 30 minutes to obtain a gas diffusion layer with cracks. The gas diffusion layer was assembled into a fuel cell and tested in the same way as in Comparative Example 1.

Embodiment 2

[0027] Mix 1.5g of carbon powder (Vulcan XC-72) and 15g of deionized water and stir uniformly, then add 0.6g of 60% polytetrafluoroethylene (PTFE) emulsion and 0.375g of ammonium carbonate in sequence, and mix evenly to obtain a slurry . The slurry is coated on the side of the base layer that has been hydrophobicized and dried in advance by a knife coating method to obtain a gas diffusion layer (loading 2.0mg / cm 2 ). Place the gas diffusion layer in an oven at 150°C for drying, and then transfer to a N-pass 2 Sintered in a tube furnace at 350°C for 30 minutes to obtain a gas diffusion layer with larger cracks. The gas diffusion layer was assembled into a fuel cell and tested in the same way as in Comparative Example 1.

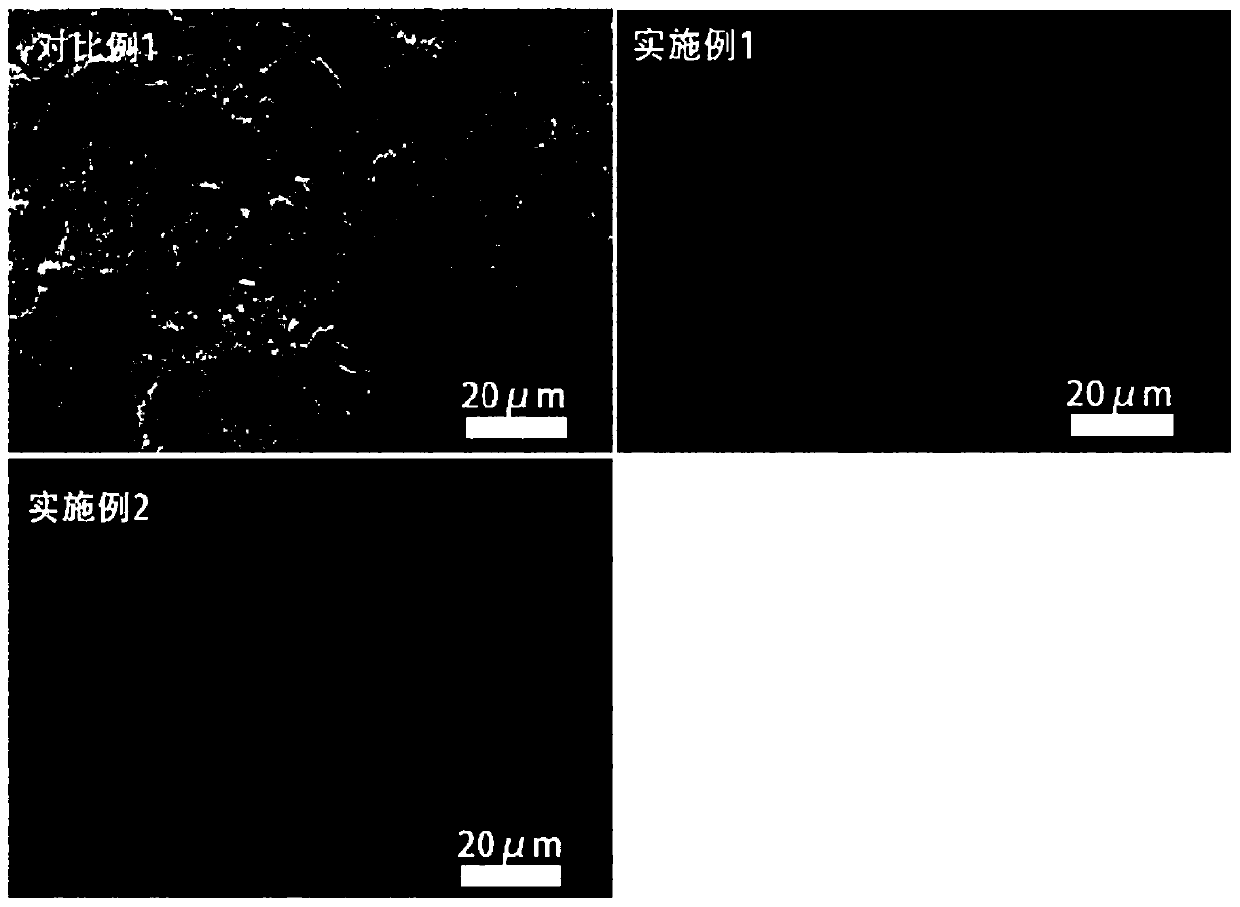

[0028] figure 1 SEM images of the gas diffusion layer microporous layer obtained in Example 1-2 and Comparative Example 1. It can be seen from the figure that there are no obvious cracks on the surface of the microporous layer in Comparative Example 1, while th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com