Method for producing whole-fat high-energy low-gossypol high-quality cottonseed kernels through bacterial enzyme collaborative glycolysis

A zymolysis and full-fat technology, which is applied in animal husbandry, food science, animal feed, etc., can solve problems such as use restrictions, and achieve the effects of promoting animal growth, inhibiting digestive tract diseases, and inhibiting growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

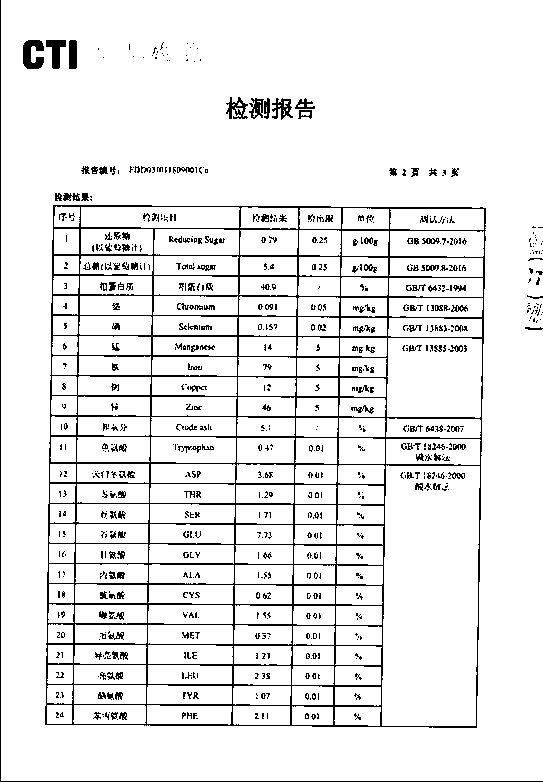

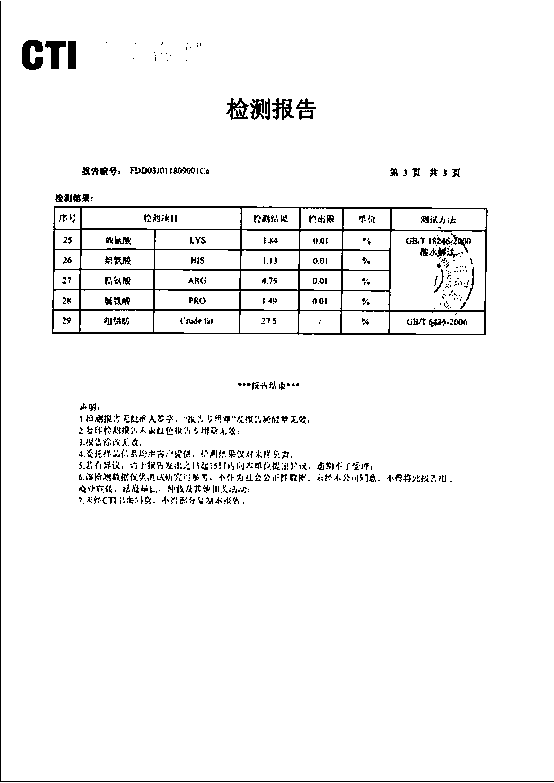

[0020] A method for producing full-fat, high-energy, low-gossypol and high-quality cotton kernels through co-fermentation with bacteria and enzymes comprises the following steps:

[0021] 1) Heat treatment: After the cotton kernels are shelled and cake-pressed, add 40% water, heat-treat at 120°C for 25 minutes, dry at 50°C, and pulverize;

[0022] 2) Bacterial enzyme coordinated fermentation: inoculate 0.6% Bacillus subtilis seed liquid and 1.5% Saccharomyces cerevisiae seed liquid into cooled cotton kernels, add alkaline protease 50 u / g, mix well and place at 30°C 24 hours, during which the material was turned twice, and after the fermentation was completed, it was dried at 50°C to obtain full-fat, high-energy, low-gossypol and high-quality cotton kernels.

[0023] The preparation step of Bacillus subtilis seed solution is to inoculate the Bacillus subtilis bacillus subtilis whose preservation number is CCTCC NO: M 2017591 on the slant medium for activation, and then use the ...

Embodiment 2

[0026] A method for producing full-fat, high-energy, low-gossypol and high-quality cotton kernels through co-fermentation with bacteria and enzymes comprises the following steps:

[0027] 1) Heat treatment: After the cotton kernels are shelled and cake-pressed, add 45% water, heat-treat at 125°C for 22 minutes, dry at 45°C, and pulverize;

[0028] 2) Bacteria-enzyme coordinated fermentation: Inoculate 0.7% Bacillus subtilis seed liquid and 1.8% Saccharomyces cerevisiae seed liquid into cooled cotton kernels, add alkaline protease 60 u / g, mix well and place at 28°C 24 hours, during which the material was turned twice, and after the fermentation was completed, it was dried at 50°C to obtain full-fat, high-energy, low-gossypol and high-quality cotton kernels.

[0029] The preparation step of Bacillus subtilis seed solution is to inoculate the Bacillus subtilis bacillus subtilis with the preservation number of CCTCC NO: M 2017591 on the slant medium for activation, and then use th...

Embodiment 3

[0032] Get 1000kg cotton kernel, measure the content of its components such as crude protein, crude fat, crude fiber, free gossypol and amino acid, it is randomly divided into two parts, one part is used as the test group, and processed according to the following steps:

[0033] 1) Heat treatment: After the cotton kernels are shelled and cake-pressed, add 43% water, heat-treat at 130°C for 20 minutes, dry at 45°C, and pulverize;

[0034] 2) Bacteria and enzyme coordinated fermentation: inoculate 0.8% Bacillus subtilis seed liquid and 1.5% Saccharomyces cerevisiae seed liquid into cooled cotton kernels, add alkaline protease 60 u / g, mix well and place at 28°C 24 hours, during which the material was turned twice, and after the fermentation was completed, it was dried at 50°C to obtain full-fat, high-energy, low-gossypol and high-quality cotton kernels. Wherein, the preparation step of the Bacillus subtilis seed solution is to inoculate the Bacillus subtilis with the preservation n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com