Photo-Fenton oxidation catalyst as well as preparation method and application thereof

A Fenton oxidation and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of unsatisfactory treatment effect, high degradation efficiency, unpredictable catalytic effect, etc. The effect of low production cost, good stability, large specific surface area and specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Select the dewatered dry sludge from a municipal sewage plant, knead the dry sludge and dry it in an oven at 105°C to a constant weight, then put it in a crusher and crush it for 60 seconds. The crushed particles are obtained through a 120 mesh screen. Original sludge with uniform particles;

[0035] (2) Put the sieved sludge sample obtained in step (1) into a tube furnace for calcination, at 500mL / minN 2 In the atmosphere, the calcining temperature is 600°C, calcining for 4 hours, and cooling to room temperature.

[0036] (3) Take 1g of the sludge calcined in step (2), and add 20mL of 6mol / LH to 1g of sludge. 2 SO 4 For surface modification, control the modification temperature to -20°C and the soaking time to 24h. After soaking, the modified sludge peat is washed with pure water until the effluent pH is neutral, and then dried in an oven at a temperature of 30°C for 12 hours to obtain the required catalyst.

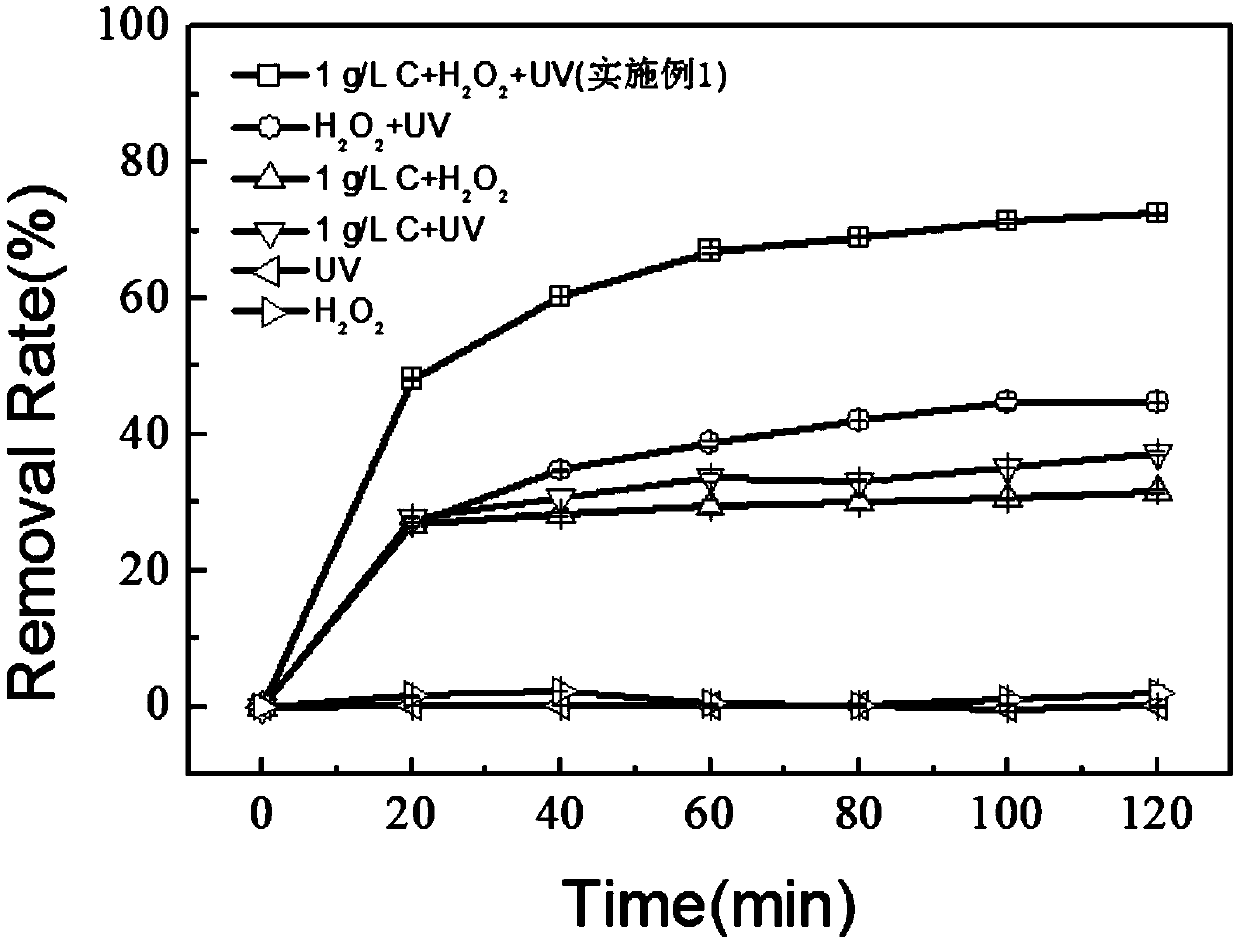

[0037] (4) The catalyst is used to treat ciprofloxacin wastew...

Embodiment 2

[0039] (1) Select the dewatered dry sludge from a municipal sewage plant, knead the dry sludge and dry it in an oven at 105°C to a constant weight, then put it in a crusher and crush it for 60 seconds. The crushed particles are obtained through a 120 mesh screen. Original sludge with uniform particles;

[0040] (2) Put the sieved sludge sample obtained in step (1) into a tube furnace for calcination, at 500mL / minN 2 In the atmosphere, the calcining temperature is 600°C, calcining for 4 hours, and cooling to room temperature.

[0041] (3) Take 1g of the sludge calcined in step (2), and add 20mL of 3mol / LH to 1g of sludge. 2 SO 4 For surface modification, control the modification temperature to -20°C and the soaking time to 24h. After soaking, the modified sludge is washed with pure water until the pH of the effluent is neutral, and then dried in an oven at a temperature of 30°C for 12 hours to obtain the required catalyst.

[0042] (4) The catalyst is used to treat ciprofloxacin wast...

Embodiment 3

[0044] (1) Select the dewatered dry sludge from a municipal sewage plant, knead the dry sludge and dry it in an oven at 105°C to a constant weight, then put it in a crusher and crush it for 60 seconds. The crushed particles are obtained through a 120 mesh screen. Original sludge with uniform particles;

[0045] (2) Put the sieved sludge sample obtained in step (1) into a tube furnace for calcination, at 150mL / minN 2 In the atmosphere, the calcining temperature is 500°C, calcining for 6 hours, and cooling to room temperature.

[0046] (3) Take 1g of the sludge calcined in step (2), and add 10mL of 6mol / LH to 1g of sludge. 2 SO 4 And 10mL of 6mol / LHNO 3 Place in the refrigerator for surface modification, control the modification temperature at 0°C, and the soaking time at 24h. After soaking, the modified sludge is washed with pure water until the pH of the effluent is neutral, and then dried in an oven at a temperature of 30°C for 12 hours to obtain the required catalyst.

[0047] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com