Hydrophobic graphene aerogel and preparation method and application thereof

A graphene aerogel, graphene hydrogel technology, applied in aerogel preparation, graphene, separation methods and other directions, can solve problems such as low hydrophobicity, improve hydrophobic performance, reduce preparation cost, reduce energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the hydrophobic graphene airgel of the present invention comprises: a preparation step and a soaking step of the graphene airgel. A detailed description is given below.

[0028]

[0029] The preparation step of graphene airgel comprises: (1) the step of preparing graphene oxide dispersion; (2) the step of preparing foam; (3) the step of preparing graphene hydrogel; (4) washing graphene water The step of gelling; (5) the step of freezing and drying under normal pressure.

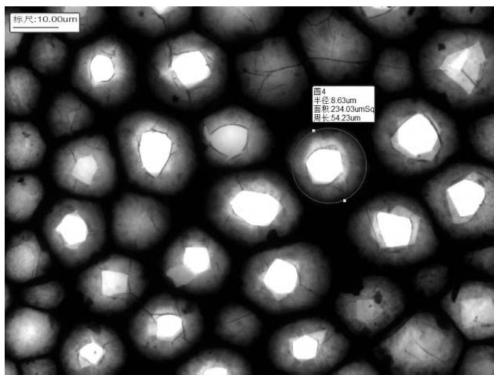

[0030] In step (1), the graphene oxide and the reducing agent are added into water to disperse uniformly to obtain a graphene oxide dispersion. In order to disperse the graphene oxide in water more fully, ultrasonic dispersion can be used for 10-30 minutes. The graphene oxide sheet diameter may be 5-40 μm; preferably, the graphene oxide sheet diameter is 10-35 μm; more preferably, the graphene oxide sheet diameter is 20-45 μm. Using the graphene oxide with the above sheet...

Embodiment 1

[0056] (1) Add 480 mg of ascorbic acid and 240 mg of graphene oxide into 60 ml of water, disperse evenly by ultrasonic oscillation for 15 minutes, and obtain a graphene oxide dispersion liquid with a graphene oxide concentration of 4 mg / ml.

[0057] (2) Add 3 ml of sodium dodecylbenzenesulfonate aqueous solution with a concentration of 50 mg / ml into the graphene oxide dispersion, and stir at a speed of 10000 rpm to obtain a foam.

[0058] (3) Put the foam at 80° C. for 6 hours of reduction reaction, and then cool it down to 25° C. to obtain graphene hydrogel.

[0059] (4) immerse and wash the graphene hydrogel with 1 vol% ethanol aqueous solution for 24 hours to obtain the graphene hydrogel after washing.

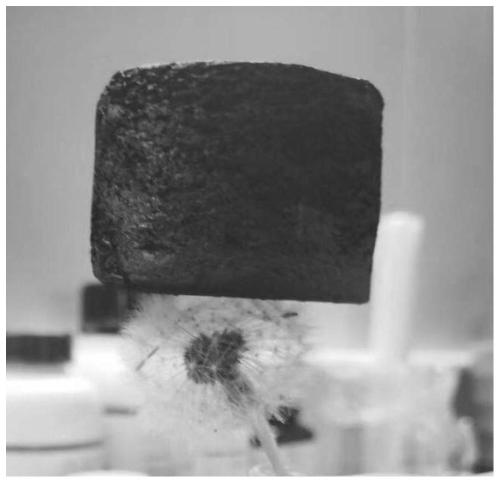

[0060] (5) Take the washed graphene hydrogel out and freeze it at -45°C, then take it out and heat it up to 25°C to melt, and then dry it under normal pressure to obtain the graphene aerogel.

[0061] (6) Soak the graphene airgel in a mixed solution containing ammonia wate...

Embodiment 2

[0063] (1) Add 480 mg of ascorbic acid and 300 mg of graphene oxide into 60 ml of water, disperse evenly by ultrasonic oscillation for 15 minutes, and obtain a graphene oxide dispersion liquid with a graphene oxide concentration of 5 mg / ml.

[0064] (2) Add 3 ml of sodium dodecylbenzenesulfonate aqueous solution with a concentration of 50 mg / ml into the graphene oxide dispersion, and stir at a speed of 10000 rpm to obtain a foam.

[0065] (3) Put the foam at 80° C. for 6 hours of reduction reaction, and then cool it down to 25° C. to obtain graphene hydrogel.

[0066] (4) immerse and wash the graphene hydrogel with 1 vol% ethanol aqueous solution for 24 hours to obtain the graphene hydrogel after washing.

[0067] (5) Take the washed graphene hydrogel out and freeze it at -45°C, then take it out and heat it up to 25°C to melt, and then dry it under normal pressure to obtain the graphene aerogel.

[0068] (6) Put the graphene airgel in a mixed solution containing ammonia and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com