Equipment for waste liquid treatment in preparation of 3D printing consumables

A waste liquid treatment and 3D printing technology, applied in the direction of neutralization water/sewage treatment, filtration treatment, sedimentation treatment, etc., can solve the problems of low utilization rate, insignificant sewage treatment effect, scattered ABS sewage treatment, etc., to improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

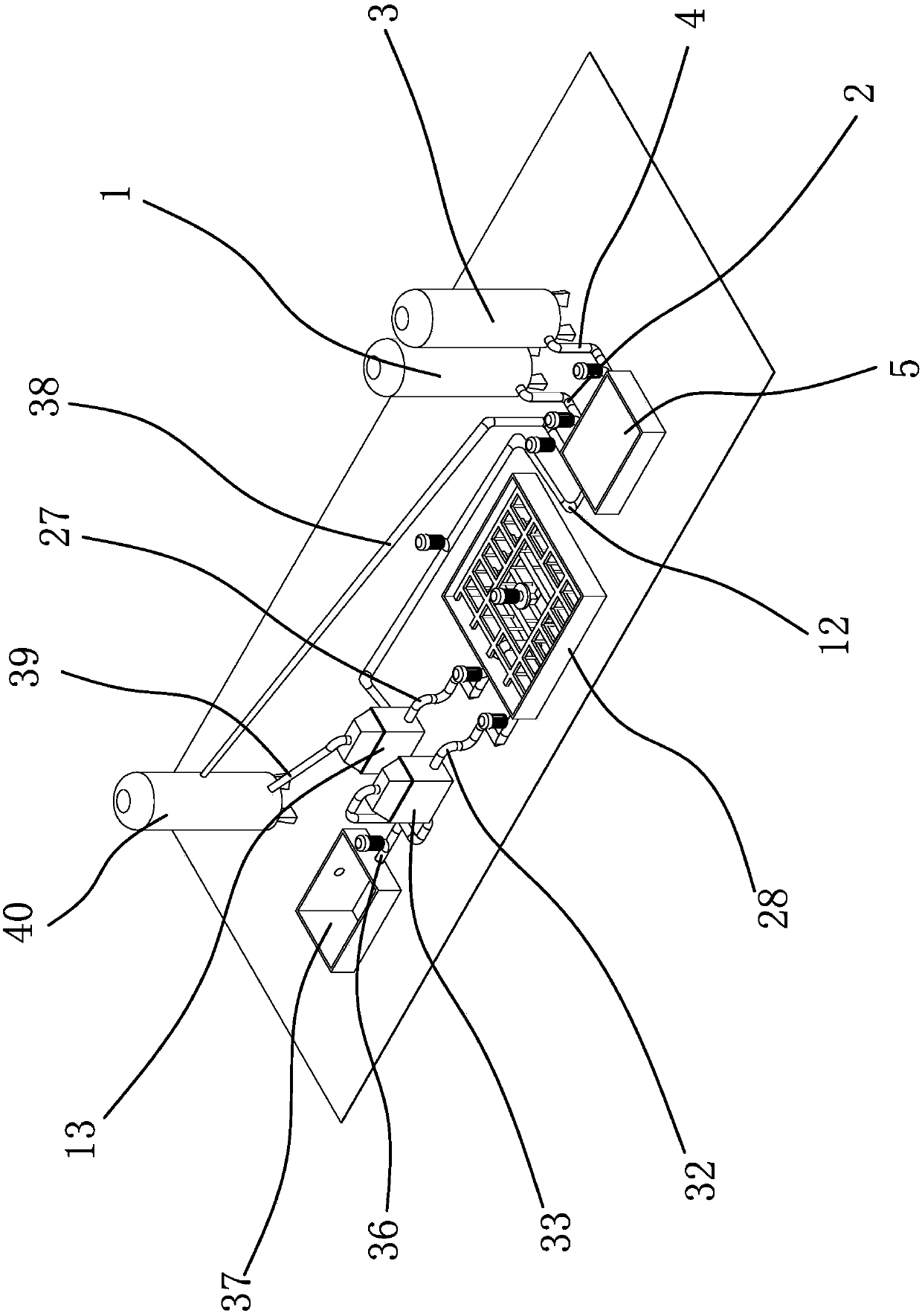

[0037] Such as figure 1 As shown, the equipment used for waste liquid treatment in the preparation of 3D printing consumables includes a workbench 41, and the workbench 41 is provided with a liquid storage tank 1, a liquid storage tank 3, a sedimentation tank 5, a filter 13, a good Oxygen pool 28, filter two 33, liquid collection pool 37 and waste tank 40; liquid storage tank one 1 is used to store acid waste liquid, and liquid storage tank two 3 is used to store alkaline waste liquid. The waste tank 40 has a collection chamber, and a partition plate is fixed in the waste collection chamber, and the partition plate divides the collection chamber into an upper collection chamber and a lower collection chamber, and the waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com