Preparation method of high purity domestic fungus vitamin D2 extract

A preparation process and high-purity technology, applied in the production of bulk chemicals, organic chemistry, etc., can solve the problems of low efficiency and long time required, and achieve the effect of reducing by-products and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

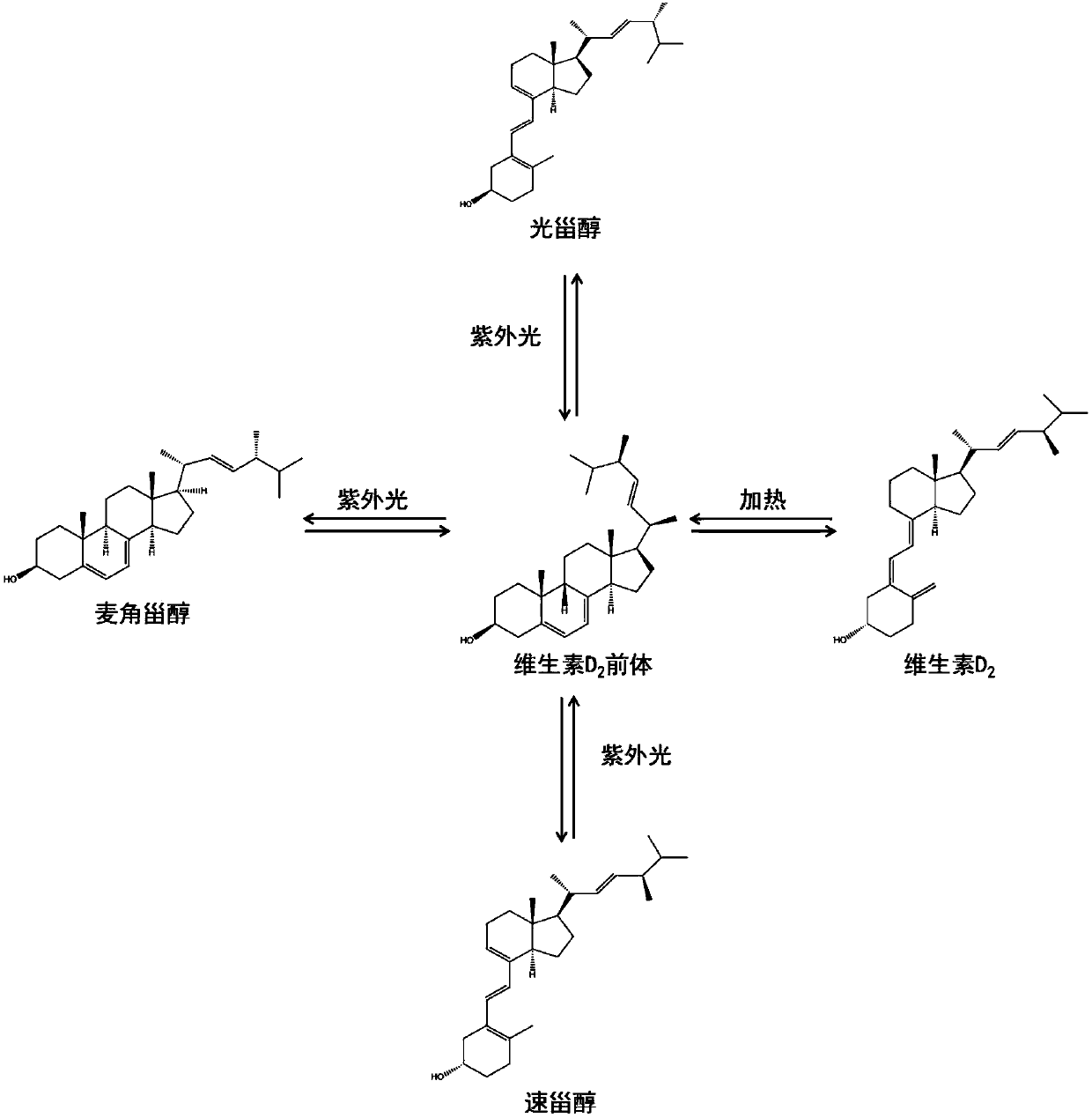

Method used

Image

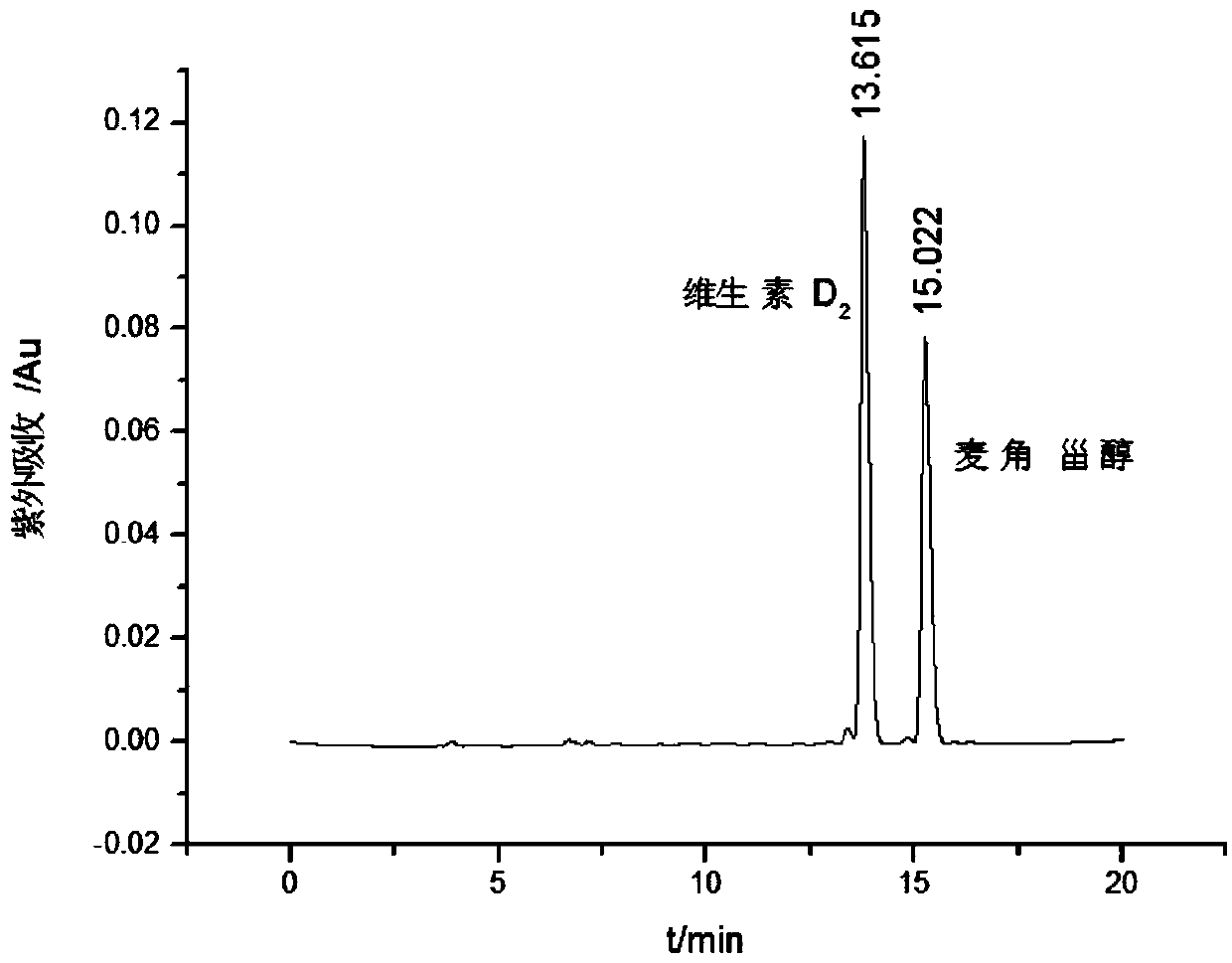

Examples

Embodiment 1

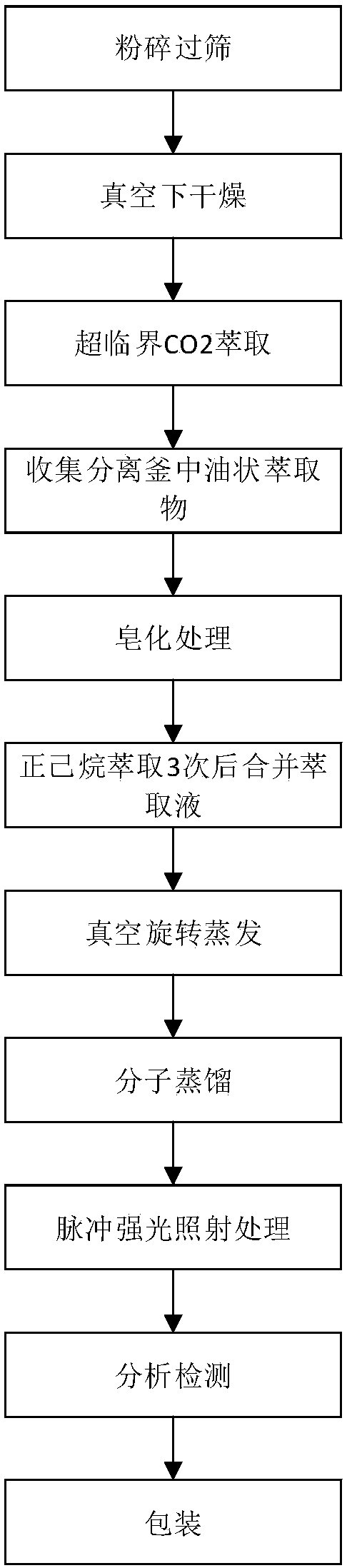

[0036] S1: crush the dried fruiting bodies of Hericium erinaceus and sieve with 40 meshes.

[0037] S2: After sieving, dry under vacuum at 60° C. for 1 hour. The drying equipment adopts the German Binder binder VD23 vacuum drying oven.

[0038] S3: After drying for 1 hour, weigh 150g and put it into the extraction kettle. 2 extraction. The extraction equipment adopts the American Thar supercritical fluid ultrafine micro-granulation system SFP, the extraction pressure is set to 35MPa, the time is 3h, the temperature is 50°C, and the CO 2 The flow rate was 20 g / min.

[0039] S4: Collect the oily extract in the separation kettle.

[0040] S5: Carry out saponification treatment on the collected oily extract, the saponification temperature is 85° C., and the saponification time is 30 min.

[0041] S6: After saponification, extract with 150 mL of n-hexane for 3 times and combine the extracts.

[0042] S7: After the extraction of n-hexane, vacuum rotary evaporation was performe...

Embodiment 2

[0049] A high-purity edible mushroom vitamin D 2 The preparation technology of extract comprises the following steps:

[0050] S1: Crush the mushroom seeds and sieve them through a 30-mesh sieve.

[0051] S2: After sieving, dry under vacuum at 50° C. for 1 hour. The drying equipment adopts the German Binder binder VD23 vacuum drying oven.

[0052] S3: After drying for 1 hour, weigh 160g and put it into the extraction kettle. 2 extraction. The extraction equipment adopts the American Thar supercritical fluid ultra-fine granulation system SFP, the extraction pressure is set to 25MPa, the time is 1h, the temperature is 45°C, CO 2 The flow rate was 10 g / min.

[0053] S4: Collect the oily extract in the separation kettle.

[0054] S5: Perform saponification treatment on the collected oily extract, the saponification temperature is 70° C., and the saponification time is 20 minutes.

[0055] S6: After saponification, extract with 100 mL of n-hexane for 3 times and combine the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com