Wind erosion-resistant modified polyurethane sand-fixing soil-repairing agent and preparation method

A technology for repairing soil and polyurethane, which is applied in the direction of soil protection, soil conditioning materials, chemical instruments and methods, etc., can solve problems such as large-scale damage, insufficient strength and toughness, and poor wind erosion resistance, so as to prolong the service life and improve Strength and toughness, effect of improving wind erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

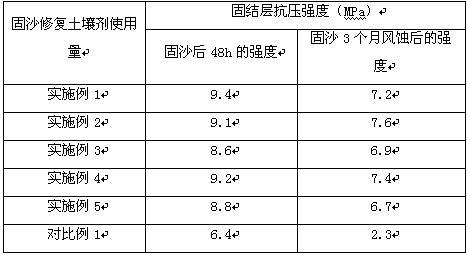

Examples

Embodiment 1

[0036] The sand-fixing and repairing soil agent is composed of A component of lignin nitrate modified by diatomite and B component composed of linear polyurethane prepolymer; a preparation method of a wind erosion-resistant modified polyurethane sand-fixing and repairing soil agent consists of the following steps :

[0037] (a) Preparation of component A: take water and polyethylene glycol according to the percentage by weight of 0.05:1, add polyethylene glycol into water, stir evenly to obtain a lignin derivative solvent, and set aside;

[0038] (b) first disperse 25kg of diatomaceous earth in 105kg of lignin derivative solvent prepared in step (a), then add 25kg of lignin nitrate therein, and stir at room temperature for 1.5h to obtain component A;

[0039] (c) Preparation of component B: Add polyethylene glycol with a low molecular weight of less than 1000 to the diisocyanate, stir and mix evenly, pass in nitrogen gas, react at 70°C for 4 hours, add dimethylol propionic aci...

Embodiment 2

[0042] The sand-fixing and repairing soil agent is composed of A component of lignin nitrate modified by diatomite and B component composed of linear polyurethane prepolymer; a preparation method of a wind erosion-resistant modified polyurethane sand-fixing and repairing soil agent consists of the following steps :

[0043] (a) Preparation of component A: take water and polyethylene glycol according to the percentage by weight of 0.15:1, add polyethylene glycol into water, stir evenly to obtain a lignin derivative solvent, and set aside;

[0044] (b) First disperse 25kg of diatomaceous earth in 120kg of lignin derivative solvent prepared in step (a), then add 25kg of lignin nitrate to it, and stir at room temperature for 1.5h to obtain component A;

[0045] (c) Preparation of component B: Add polyethylene glycol with a low molecular weight of less than 1000 to the diisocyanate, stir and mix evenly, pass in nitrogen gas, react at 70°C for 4 hours, add dimethylol propionic acid ...

Embodiment 3

[0048] The sand-fixing and repairing soil agent is composed of A component of lignin nitrate modified by diatomite and B component composed of linear polyurethane prepolymer; a preparation method of a wind erosion-resistant modified polyurethane sand-fixing and repairing soil agent consists of the following steps :

[0049] (a) Preparation of component A: take water and polyethylene glycol according to the percentage by weight of 0.10:1, add polyethylene glycol into water, stir evenly to obtain a lignin derivative solvent, and set aside;

[0050] (b) First disperse 45kg of diatomaceous earth in 120kg of lignin derivative solvent prepared in step (a), then add 25kg of lignin nitrate therein, and stir at room temperature for 1.5h to obtain component A;

[0051] (c) Preparation of component B: Add polyethylene glycol with a low molecular weight of less than 1000 to the diisocyanate, stir and mix evenly, pass in nitrogen gas, react at 70°C for 4 hours, add dimethylol propionic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com