Manufacturing method of embedded flash memory

A manufacturing method and embedded technology, applied in the direction of electrical components, electrical solid-state devices, circuits, etc., can solve the problems of increasing the manufacturing cost of embedded flash memory and increasing the complexity of the manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

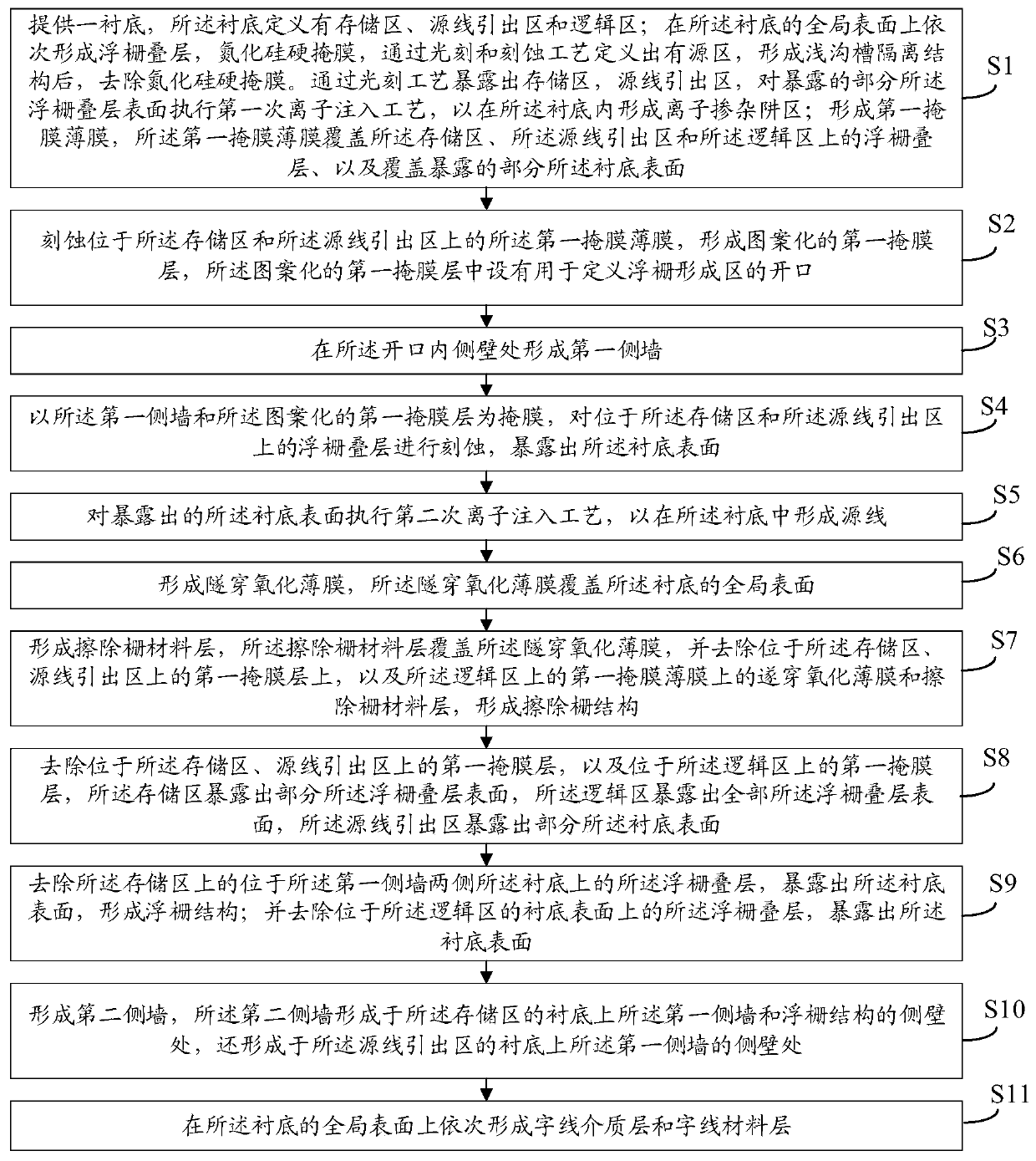

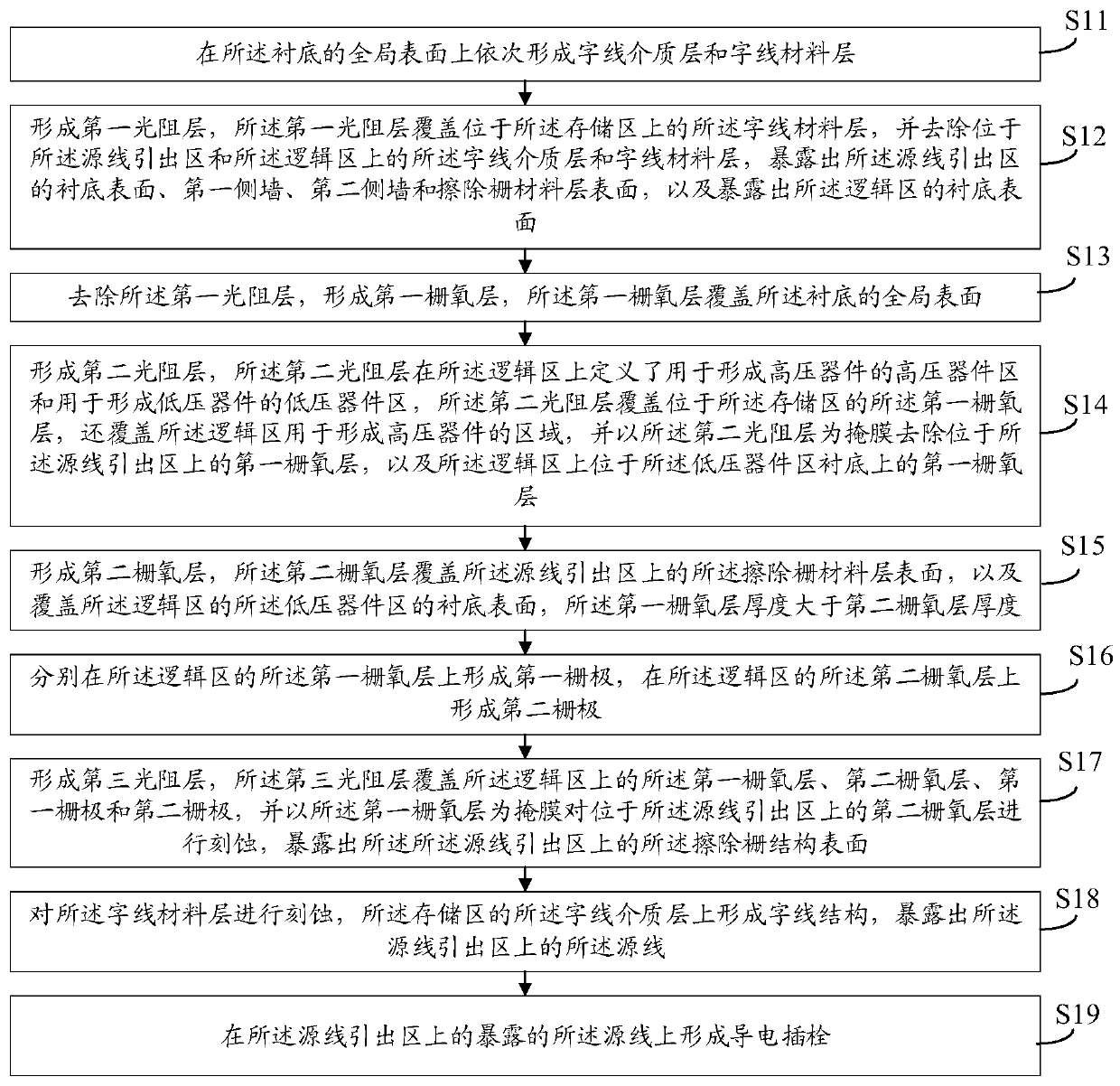

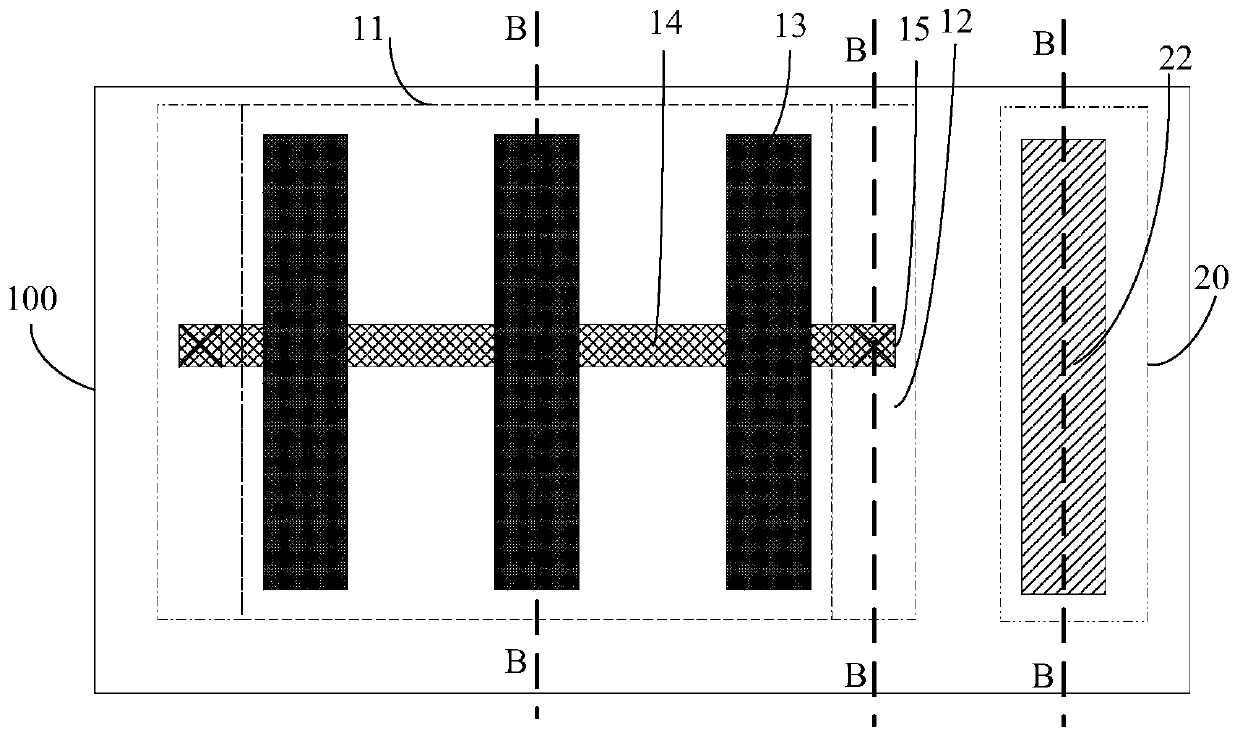

[0025] As described in the background, in the prior art, when preparing the conductive plug used to lead out the source line, additional photomasks and photolithography steps are used to increase the manufacturing cost of preparing the embedded flash memory. The problem of increasing the complexity of its manufacturing process is that the processes of memory cells (storage area) and logic transistors (logic area or peripheral area) are often performed on the same substrate at the same time. In the existing embedded flash memory manufacturing process, the embedded source line (Source line) is used as a buried layer under the erase gate (erase gate, EG) of the embedded flash memory, and the source line needs to use an additional Define the photomask with the pattern of the conductive plug leading out the source line, and remove the erasing gate material layer in the area used to form the conductive plug in combination with the photolithography process, The region forms a conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com