A nickel-based arc spraying flux-cored welding wire and its preparation method

A technology of arc spraying and flux-cored welding wire, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of natural ecological damage, oil pipeline leakage, easy corrosion, etc., achieve small spatter, stable arc, spray coating uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

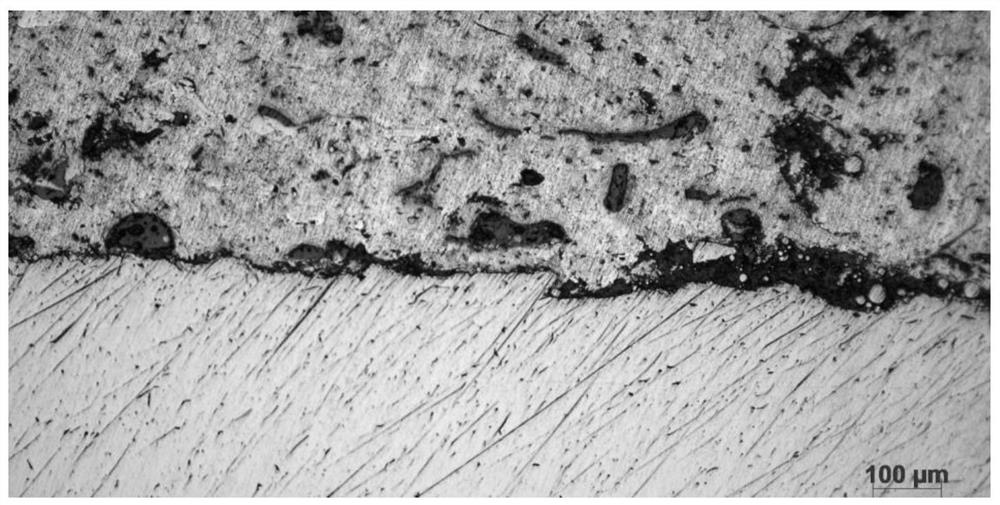

[0026] See figure 1 , Figure 5 A flux-cored welding wire for nickel-based arc spraying, including a nickel-chromium strip sheath and alloy powder wrapped therein, the alloy powder comprising by weight:

[0027] 15 parts of micro-carbon ferrochromium powder, 4.5 parts of high-carbon ferromanganese powder, 6 parts of ferromolybdenum powder, 55 parts of nickel powder, 7 parts of magnesium aluminum powder, 7 parts of reduced iron powder, 4 parts of rutile powder, 1 part of feldspar powder, Fluorite powder 0.2 part, sodium fluorosilicate 0.3 part.

[0028] The preparation method of nickel-based arc spraying flux-cored welding wire is to mix rutile powder, feldspar powder and fluorite powder and heat up to 800°C, and keep it warm for 3 hours; reduce iron powder, micro-carbon ferrochrome powder, high-carbon ferromanganese powder, Powder, nickel powder, magnesium-aluminum powder and sodium fluorosilicate are mixed and heated to 300°C, kept for 2 hours, then the two parts are mixed,...

Embodiment 2

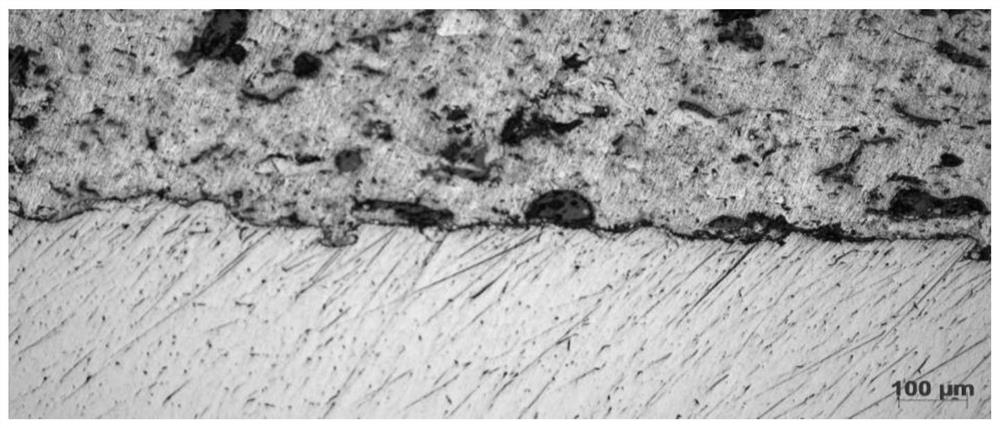

[0035] See figure 2 , Figure 5 A flux-cored welding wire for nickel-based arc spraying, including a nickel-chromium strip sheath and alloy powder wrapped therein, the alloy powder comprising by weight:

[0036] 20 parts of micro-carbon ferrochromium powder, 5 parts of high-carbon ferromanganese powder, 5 parts of ferromolybdenum powder, 51 parts of nickel powder, 5 parts of magnesium aluminum powder, 8 parts of reduced iron powder, 3 parts of rutile powder, 2.2 parts of feldspar powder, 0.4 parts of stone powder, 0.4 parts of sodium fluorosilicate.

[0037] The preparation method of nickel-based arc spraying flux-cored welding wire is to mix rutile powder, feldspar powder and fluorite powder and heat up to 800°C, and keep it warm for 3 hours; reduce iron powder, micro-carbon ferrochrome powder, high-carbon ferromanganese powder, Powder, nickel powder, magnesium-aluminum powder and sodium fluorosilicate are mixed and heated to 300°C, kept for 2 hours, then the two parts are...

Embodiment 3

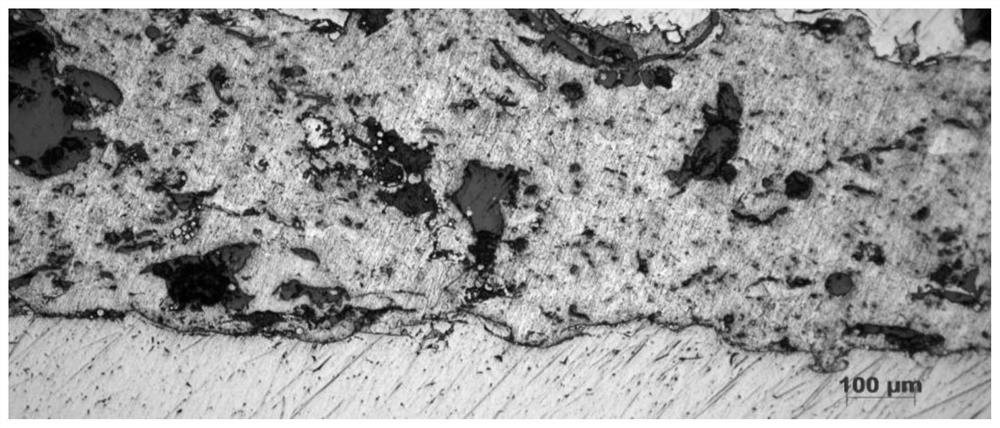

[0044] See image 3 , Figure 5 A flux-cored welding wire for nickel-based arc spraying, including a nickel-chromium strip sheath and alloy powder wrapped therein, the alloy powder comprising by weight:

[0045] 20 parts of micro-carbon ferrochrome powder, 8 parts of high-carbon ferromanganese powder, 6 parts of ferromolybdenum powder, 45 parts of nickel powder, 8 parts of magnesium aluminum powder, 7 parts of reduced iron powder, 2.4 parts of rutile powder, 3 parts of feldspar powder, 0.3 parts of fluorite powder, 0.3 parts of sodium fluorosilicate.

[0046] The preparation method of nickel-based electric arc spraying flux-cored welding wire is to mix rutile powder, feldspar powder and fluorite powder and then heat up to 800°C and keep it warm for 3 hours; Powder, nickel powder, magnesium aluminum powder and sodium fluorosilicate are mixed and heated to 300°C, and kept for 2 hours, then the two parts are mixed, heated to 300°C, kept for 2 hours, then air-cooled to room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com