Cryogenic treatment method for enhancing anti-fatigue strength of stainless steel wire mesh

A cryogenic treatment, stainless steel technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of easy fracture and deformation, and achieve the effect of economical convenience, enhanced fatigue resistance, and improved fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

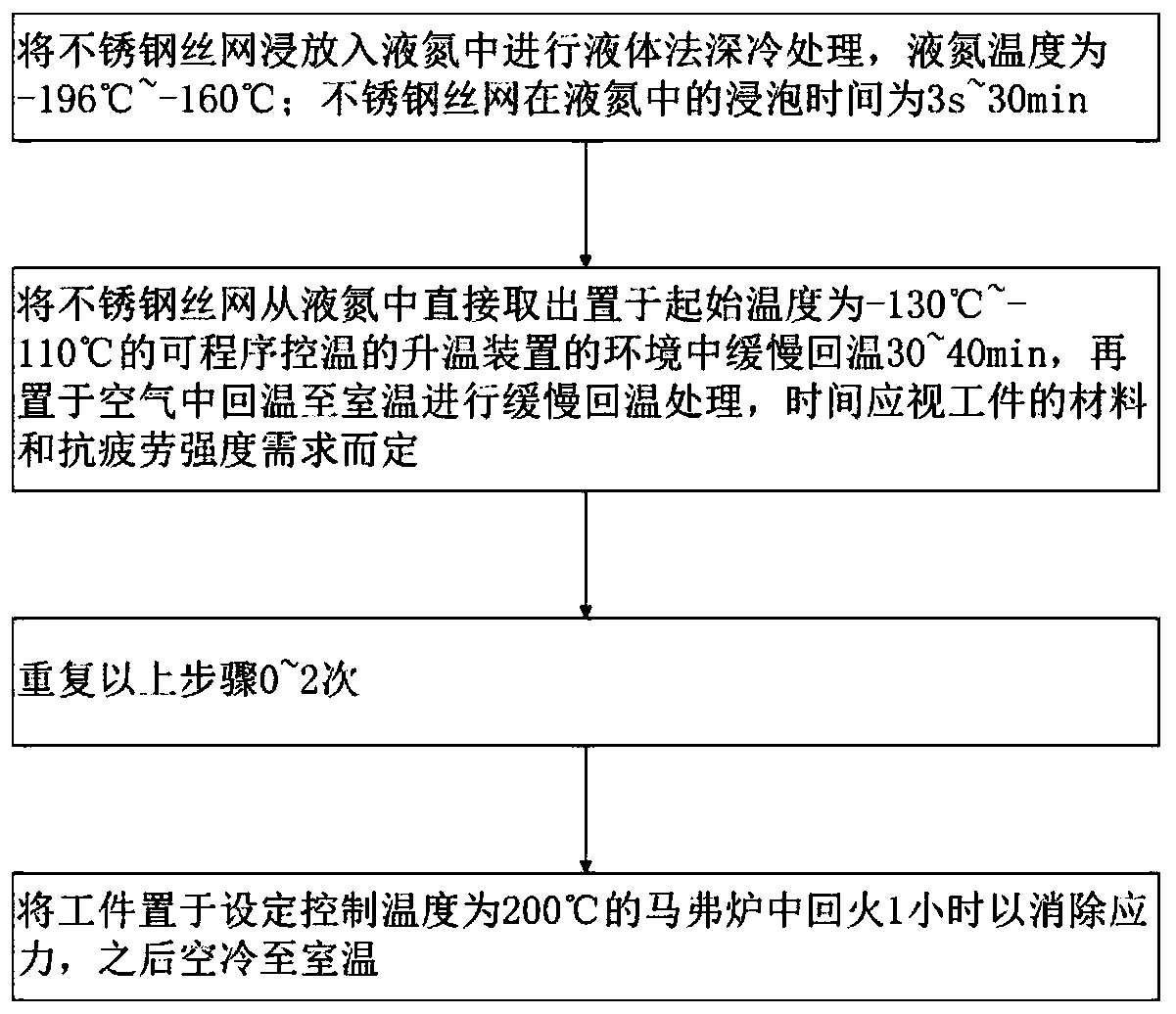

Method used

Image

Examples

Embodiment 1

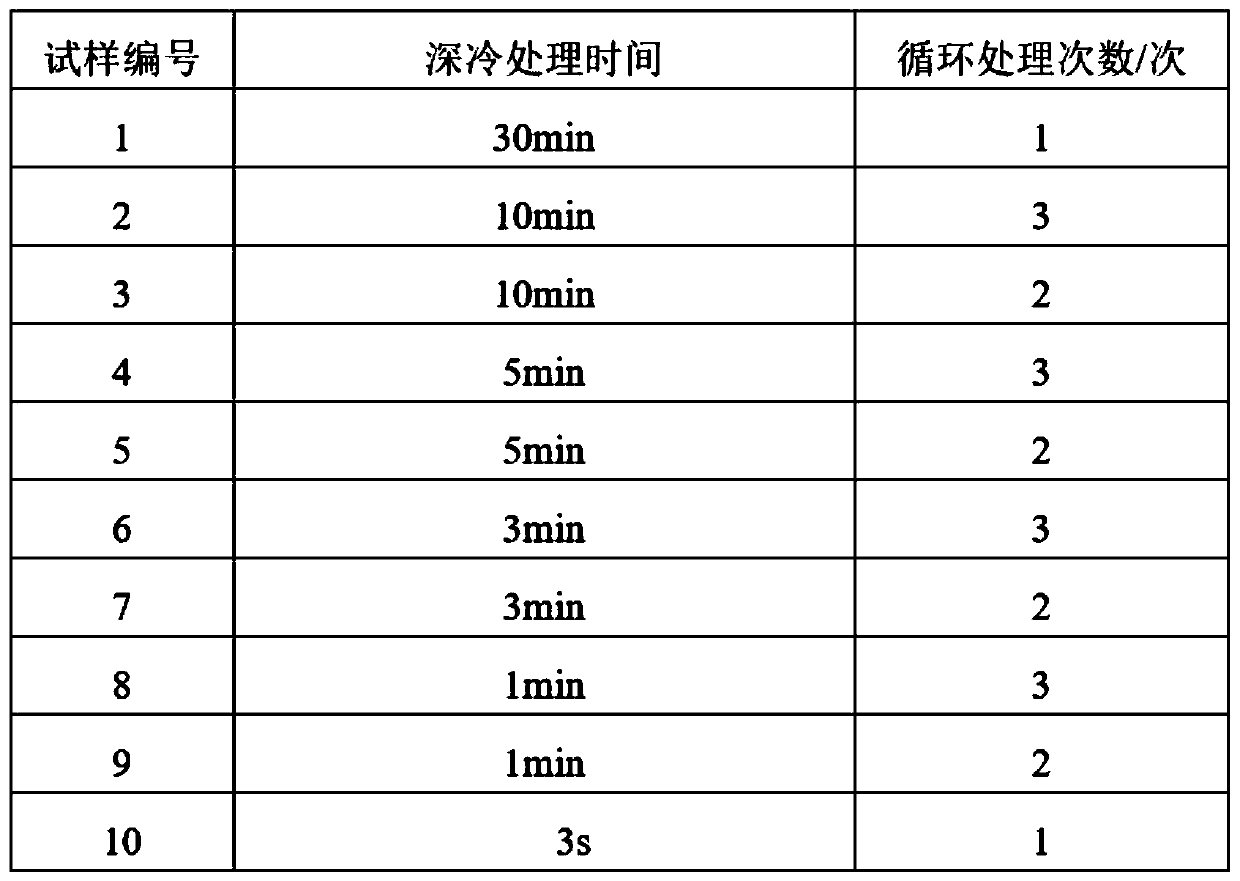

[0023] Embodiment 1: a kind of cryogenic treatment method that strengthens stainless steel wire mesh anti-fatigue strength, it is characterized in that: comprise the following steps:

[0024] (1) Dip the stainless steel wire mesh into liquid nitrogen for liquid cryogenic treatment, the liquid nitrogen temperature is -196°C; the immersion time of the stainless steel wire mesh in liquid nitrogen is 30 minutes;

[0025] (2) Take the stainless steel wire mesh out of the liquid nitrogen directly and place it in the environment of a programmable temperature heating device with an initial temperature of -130°C and slowly return to the temperature for 30 minutes, and then place it in the air to return to room temperature for slow return. heat treatment;

[0026] (2) Temper the workpiece in a muffle furnace with a set control temperature of 200°C for 1 hour to relieve stress, and then air cool to room temperature.

[0027] The stainless steel wire mesh is 316L stainless steel wire mes...

Embodiment 2

[0031] Embodiment 2: a kind of cryogenic treatment method that strengthens stainless steel wire mesh anti-fatigue strength, it is characterized in that: comprise the following steps:

[0032] (1) Dip the stainless steel wire mesh into liquid nitrogen for liquid cryogenic treatment, the liquid nitrogen temperature is -196°C; the immersion time of the stainless steel wire mesh in liquid nitrogen is 10 minutes;

[0033] (2) Take the stainless steel wire mesh out of the liquid nitrogen directly and place it in the environment of a programmable temperature heating device with an initial temperature of -130°C and slowly return to the temperature for 30 minutes, and then place it in the air to return to room temperature for slow return. heat treatment;

[0034] (3) Repeat the above steps 2 times;

[0035] (4) Temper the workpiece in a muffle furnace with a set control temperature of 200°C for 1 hour to relieve stress, and then air cool to room temperature.

[0036] The stainless st...

Embodiment 3

[0040] Embodiment 3: a kind of cryogenic treatment method that strengthens stainless steel wire mesh anti-fatigue strength, it is characterized in that: comprise the following steps:

[0041] (1) Dip the stainless steel wire mesh into liquid nitrogen for liquid cryogenic treatment, the liquid nitrogen temperature is -196°C; the immersion time of the stainless steel wire mesh in liquid nitrogen is 10 minutes;

[0042] (2) Take the stainless steel wire mesh out of the liquid nitrogen directly and place it in the environment of a programmable temperature heating device with an initial temperature of -130°C and slowly return to the temperature for 30 minutes, and then place it in the air to return to room temperature for slow return. heat treatment;

[0043] (3) Repeat the above steps once;

[0044] (4) Temper the workpiece in a muffle furnace with a set control temperature of 200°C for 1 hour to relieve stress, and then air cool to room temperature.

[0045] The stainless steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com