A kind of preparation method of anti-fibrillation cellulose fiber

A technology of cellulose and regenerated cellulose, applied in the field of fiber manufacturing, can solve the problems of poor anti-fibrillation effect, low strength, poor durability, etc., and achieve the effect of flexible method, excellent mechanical properties and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

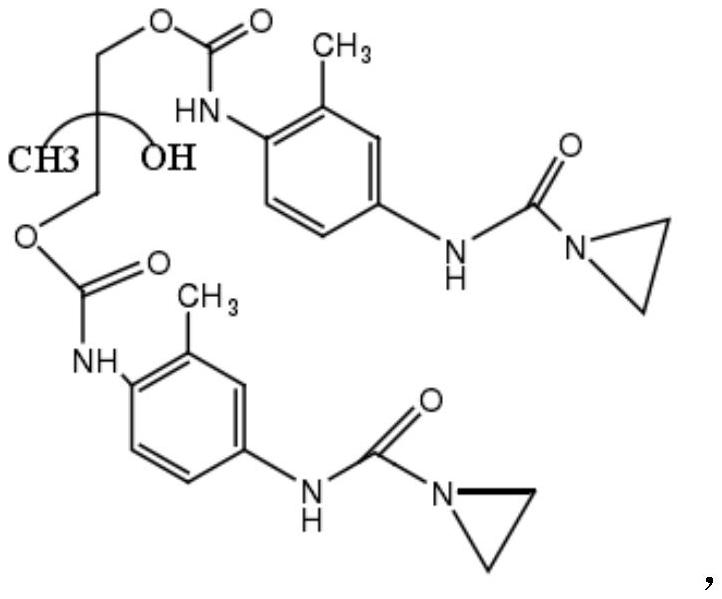

Method used

Image

Examples

Embodiment 1

[0041] Method for preparing antigen fiber cellulose fibers, the specific steps are as follows:

[0042] (1) Apparent concentration of 5% by weight of viscose fiber spinning fluid;

[0043] (2) The spinning liquid is extruded, solidified, stretched, and washed with water, washed with water, and the temperature of the water is 90 ° C, the termination conditions of the washed cleaning are: 40% by weight of the water washing wire;

[0044] (3) Soaking the water washing wire with a crosslinking agent, the crosslinking agent is 1 wt%, the crosslinking agent is a dihydroxy dihydroxy vinyl urea, and the temperature of the crosslinking agent is soaked. It is 65 ° C, soaking time is 5 seconds;

[0045] (4) Rinse and dry the soaked water washing and drying to prepare antigenic cellulose fibers, the rinsing temperature is 20 ° C, the time is 10s, the temperature of the hot air is dried, the temperature of the hot air is 95 ° C The water content of the fiber is 14.9 wt%.

[0046] The final pre...

Embodiment 2

[0058] Method for preparing antigen fiber cellulose fibers, the specific steps are as follows:

[0059] (1) Avate fiber spinning liquid having a concentration of 25 wt% was prepared;

[0060](2) extruding the dope through a spinneret, the coagulation, stretching and washing with water to obtain washed yarn, washing temperature was 99 deg.] C, washed termination condition is: the moisture content of washed silk 70wt%;

[0061] (3) with a crosslinking agent for aqueous spray washed silk, mass content of the crosslinking agent in an aqueous solution of the crosslinking agent is 10wt%, the crosslinking agent is 1,2,3,4-butane tetracarboxylic acid, spray cross-linker solution temperature was 90 ℃, spray time of 300 seconds;

[0062] (4) of the wire after washing with water and spray dried to obtain rinsing antigen cellulose fibers, rinsing temperature is 40 ℃, time is 100s, the dried hot air drying mode, the temperature of the hot air is 160 ℃, drying to a moisture content of fiber 13....

Embodiment 3

[0065] Method for preparing antigen fiber cellulose fibers, the specific steps are as follows:

[0066] (1) prepared at a concentration of 15wt% solution of Lyocell fiber;

[0067] (2) extruding the dope through a spinneret, the coagulation, stretching and washing with water to obtain washed yarn, washing temperature was 95 deg.] C, washed termination condition is: the moisture content of washed silk 55wt%;

[0068] (3) with a crosslinking agent aqueous solution washed silk soaked, the quality level of crosslinking agent in the crosslinking agent is an aqueous solution of 5wt%, the crosslinking agent is 2,4-dichloro-6-hydroxy-1,3,5 triazine, cross-linker solution soaking temperature of 75 ℃, soaking time of 100 seconds;

[0069] (4) washing the soaked yarn was rinsed and dried to obtain antigen cellulose fibers, rinsing temperature is 30 ℃, time is 50s, dried hot air drying mode, the temperature of the hot air is 125 ℃ , drying to a moisture content of fiber 14wt%.

[0070] Antige...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com