Oil-water two-phase flow measuring device and method based on combination of power rotary centrifugal differential pressure method and liquid flowmeter

A liquid flow meter and dynamic rotation technology, applied in the field of multiphase flow measurement, can solve the problems of poor real-time performance, high investment cost, poor real-time measurement performance, etc., and achieve good measurement resolution and accuracy, simple structure and processing technology, and flow measurement. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with specific embodiments, so that those skilled in the art can understand.

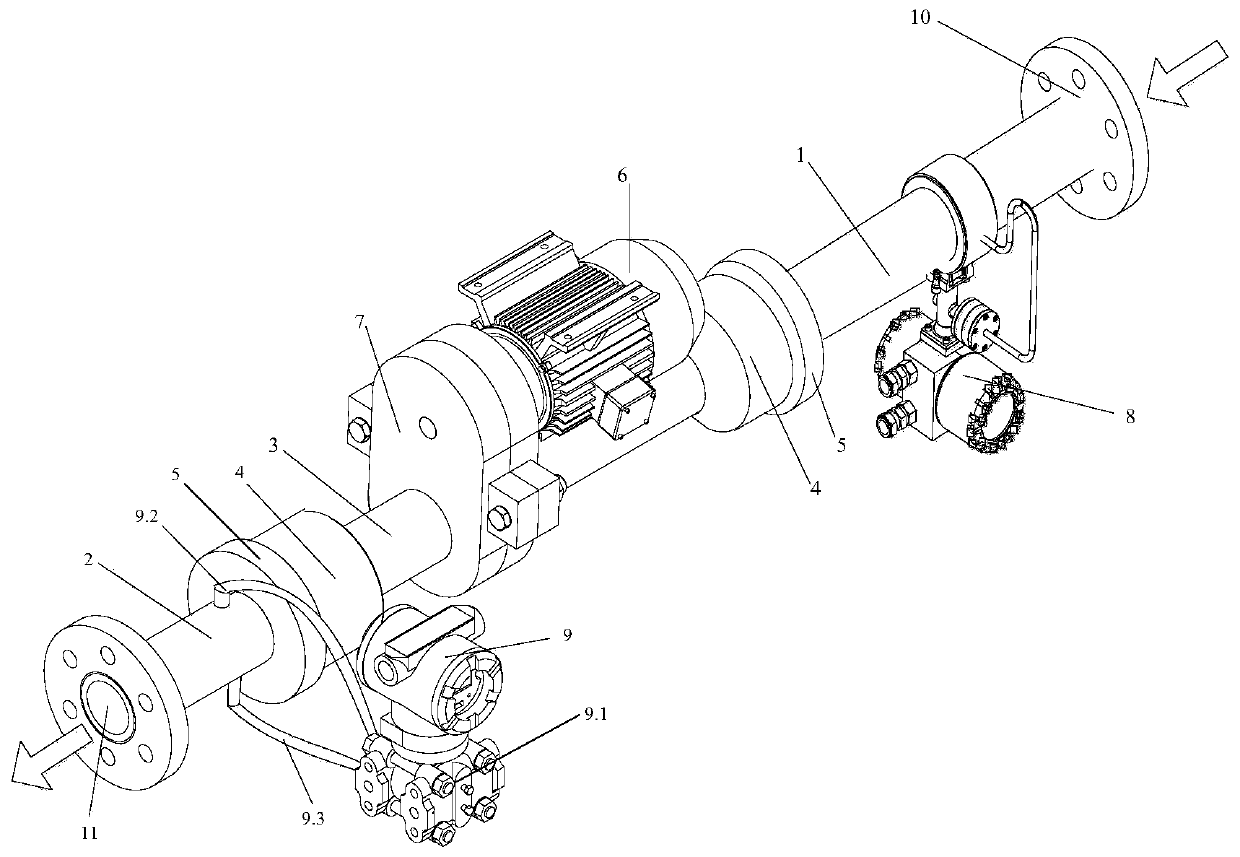

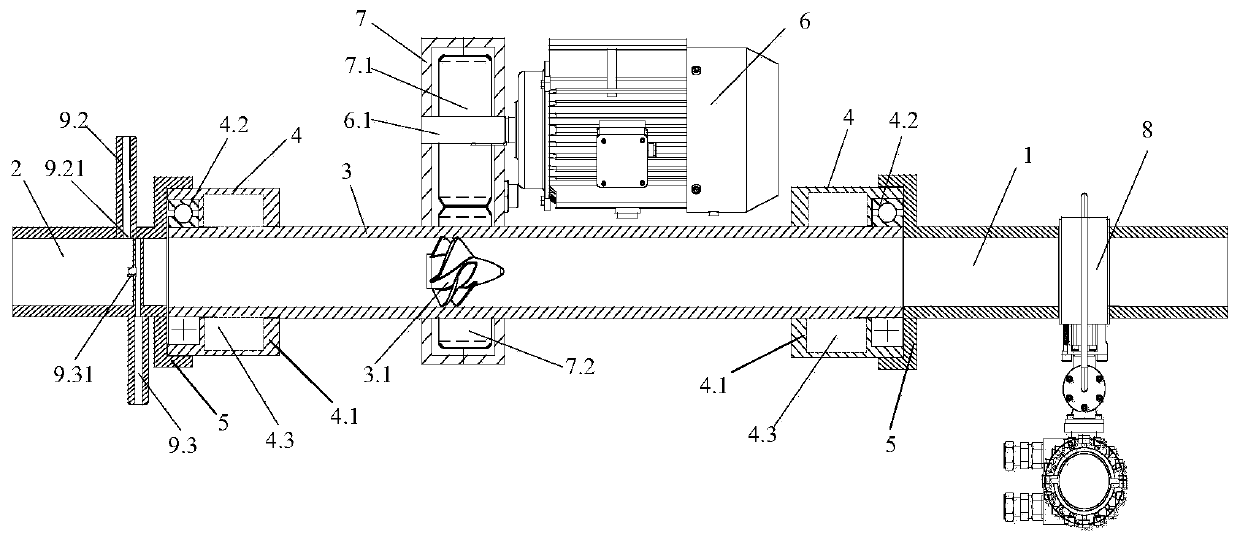

[0040] Such as Figure 1~2 The shown oil-water two-phase flow measurement device based on the combination of the power rotating centrifugal differential pressure method and the liquid flowmeter, it sequentially includes a coaxial inlet connecting flange 10, an inlet pipe 1, a power rotating pipe 3, The outlet pipe 2 and the outlet connecting flange 11; and the inner diameters of the inlet pipe 1, the power rotating pipe 3 and the outlet pipe 2 are the same, the pipe wall of the inlet pipe 1 is provided with a liquid flow meter 8, and the outer walls of the power rotating pipe 3 two ends are uniform A bearing and a sealing box 4 are provided;

[0041] The bearing and seal box 4 includes a shaft seal box 4.1 with an opening at one end and arranged on the outer wall of the power rotating tube 3, a bearing 4.2 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com