Crayfish tin can product and processing method thereof

A processing method and technology of tinplate cans, which are applied in the field of tinplate braised crayfish cans and their processing, can solve the problems of long shelf life and decline in meat taste, and achieve the effects of short heating time at high temperature, convenient eating, and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

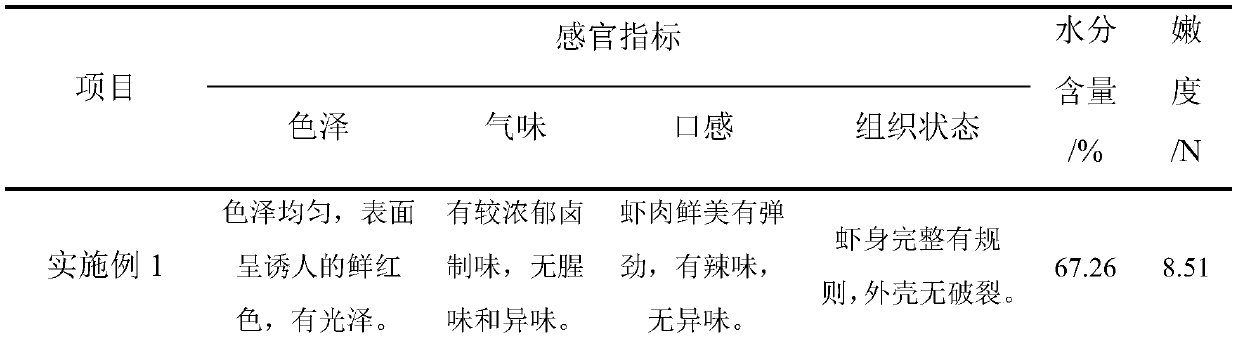

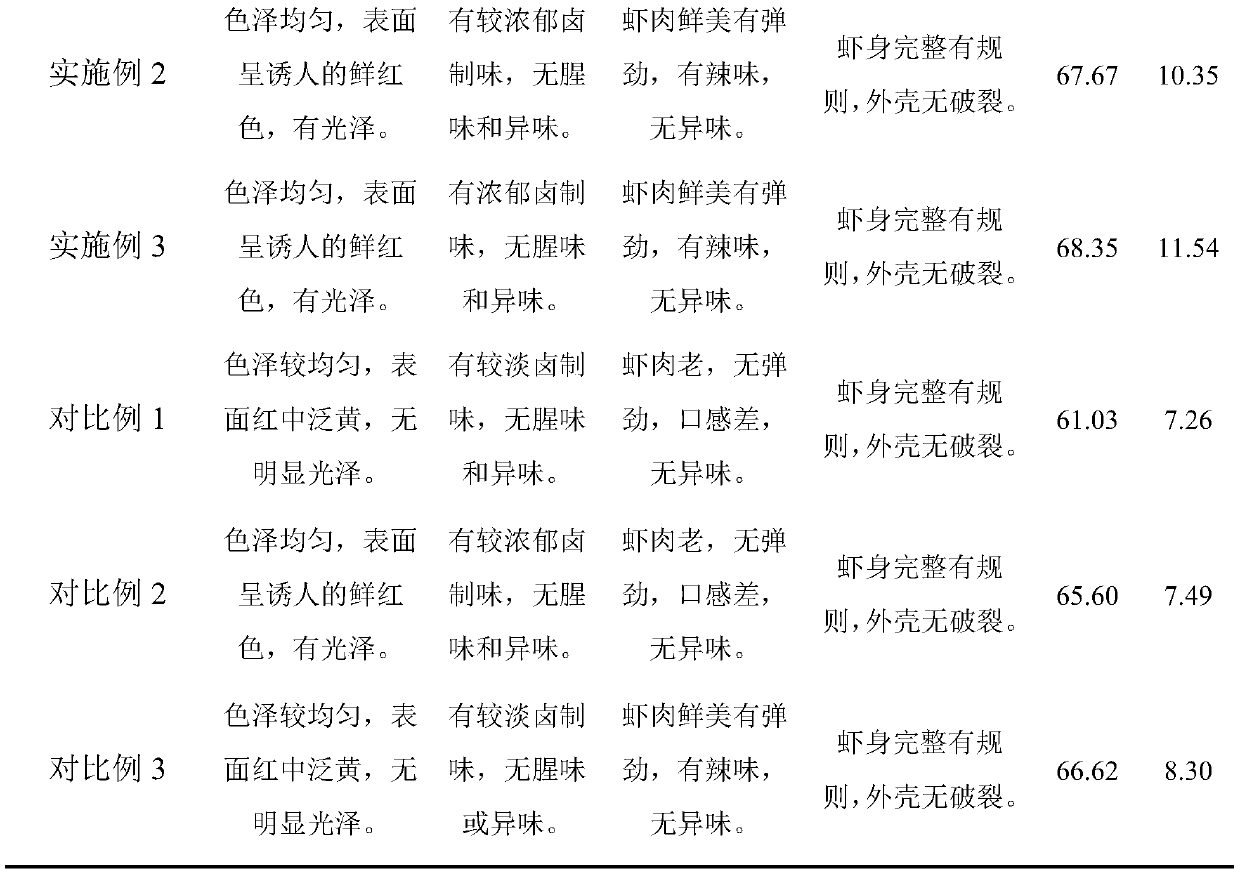

Embodiment 1

[0045] (1) Select fresh and live crayfish, each weighing between 25 and 35g.

[0046] (2) Scrub the crayfish with a brush dipped in water, then place it in a compound bacteria-reducing solution with an effective concentration of immobilized chlorine dioxide of 100 mg / L, ultrasonically clean it at a preset frequency for 1 hour, and then rewash the crayfish with running water until there is no peculiar smell , drain the water. The preset frequency refers to 1min of ultrasound at 25KHz, 1min of ultrasound at 40KHz, and 1min of ultrasound at 25KHz, repeating the above alternating ultrasound steps.

[0047] (3) put the washed and drained crayfish in proportion (the ratio of crayfish and brine is 1:3) into brine with a salt concentration of 4% (wt) and boiled, and cool the brine in the container by a cold bath, Soak for 2h.

[0048] (4) Fry the soaked crayfish in soybean oil at 130°C for 120s, remove from the pan, and cool at room temperature until the shrimp heads are not loosened....

Embodiment 2

[0051] The difference from Example 1 is that in step (5), 50 mL of boiled brine was added.

Embodiment 3

[0053] The difference from Example 1 is that in step (5), staged sterilization (80°C / 15min→100°C / 8min→121°C / 3min).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com